Vehicle purifier for in-situ degradation of VOCs

A purifying agent, a technology for vehicles, applied in chemical instruments and methods, gas treatment, membrane technology, etc., can solve problems such as human harm and secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0009] The present invention also provides a preparation method of the vehicle purifier for in-situ degradation of VOCs, comprising the following steps:

[0010] (1) Add foaming agent to polypropylene resin and mix evenly, then obtain polypropylene fiber by electrospinning, and calcinate polypropylene fiber at 300-450°C for 2-4 hours to obtain porous carbon fiber;

[0011] (2) Mix porous carbon fiber, kaolin, soluble metal salt, silane coupling agent and organic titanate in a solvent to obtain a mixed system, then add inorganic acid to adjust the pH of the mixed system to be acidic, and then sonicate for 15~ 30min, then sealed and reacted at 80-120°C for 3-6h to obtain modified porous carbon fibers;

[0012] (3) Ultrasonic disperse the modified porous carbon fiber in the solvent for 15-30 minutes, then add polydiallyldimethylammonium chloride, continue ultrasonication for 30-45 minutes, then add graphene oxide, stir for 30-45 minutes and then dry , to obtain a car purifier fo...

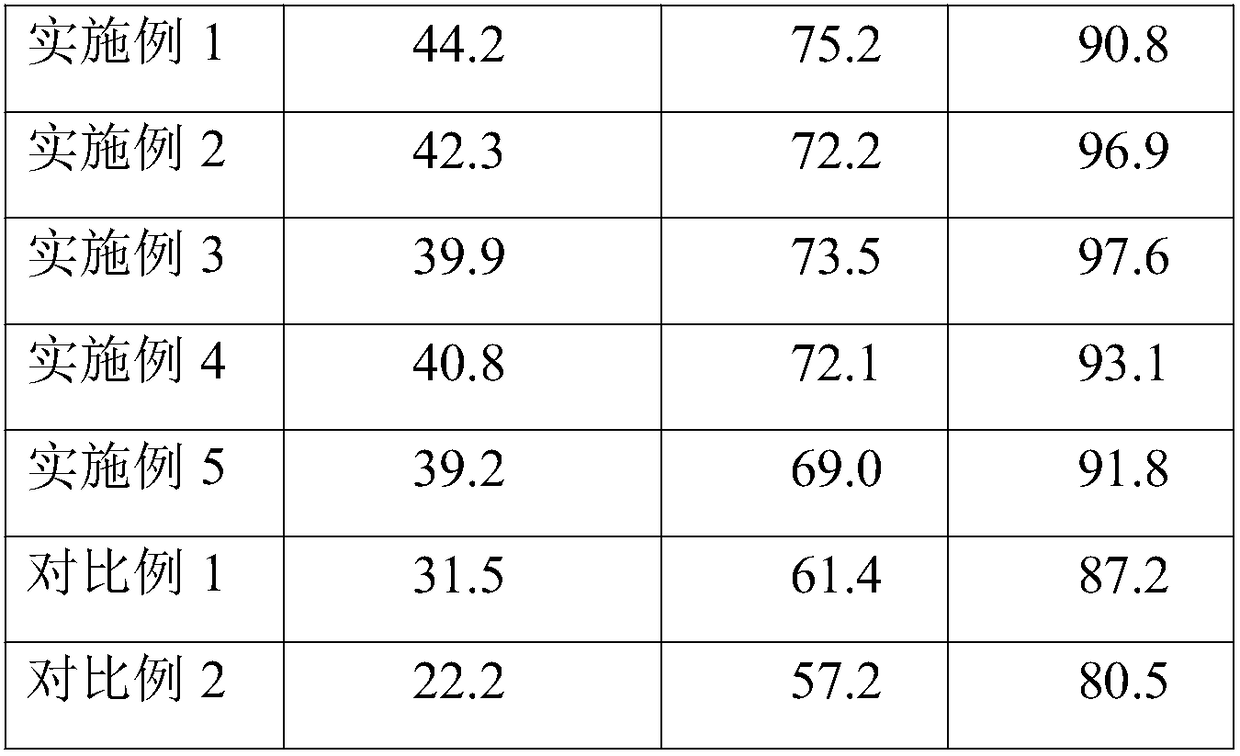

Embodiment 1

[0023] A car purifier for in-situ degradation of VOCs, made of the following parts by weight: 8 parts by weight of kaolin, 8 parts by weight of tetraethyl titanate, 0.5 parts by weight of nickel acetate, and silane coupling agent KH792

[0024] 1.5 parts by weight, 4 parts by weight of graphene oxide, 4 parts by weight of polydiallyldimethylammonium chloride, 3 parts by weight of N,N'-dinitrosopentamethylenetetramine, 105 parts by weight of polypropylene resin parts, 4 parts by weight of hydrochloric acid (2M), and 50 parts by weight of ethanol.

[0025] The preparation method of the vehicle-use purifying agent of described in-situ degradation VOCs, comprises the following steps:

[0026] (1) Add N,N'-dinitrosopentamethylenetetramine to polypropylene resin and mix evenly, then obtain polypropylene fiber by electrospinning. The electrospinning process is: power supply voltage 50kV, spinning The temperature is 35°C, the relative humidity is 75%; the needle spacing of the multi-...

Embodiment 2

[0032]A car purifier for in-situ degradation of VOCs, made of the following parts by weight: 12 parts by weight of kaolin, 5 parts by weight of tetraisopropyl titanate, 0.8 parts by weight of ferric chloride, and silane coupling agent KH5801.8 Parts by weight, 6 parts by weight of graphene oxide, 5 parts by weight of polydiallyldimethylammonium chloride, 2 parts by weight of N,N'-dinitrosopentamethylenetetramine, 100 parts by weight of polypropylene resin , 3 parts by weight of hydrochloric acid (3M), and 45 parts by weight of water.

[0033] (1) Add N,N'-dinitrosopentamethylenetetramine to polypropylene resin and mix evenly, then obtain polypropylene fiber by electrospinning. The electrospinning process is: power supply voltage 50kV, spinning The temperature is 35°C, the relative humidity is 75%; the needle spacing of the multi-needle spinneret unit is 35cm, and the number of needleheads of the spinneret unit is 90;

[0034] Calcining polypropylene fibers at 400°C for 2.5 ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com