Novel high thermal conductive stainless steel cooker manufacturing method

A stainless steel pot with high thermal conductivity technology, which is applied in the field of molten salt heat transfer, can solve the problems of inconvenient use by housewives, decreased thermal conductivity of the bottom of the pot, and heavy weight of the pot, so that it is not easy to stick to the pot and reduce heat Stress and shear force, effect of pot body weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

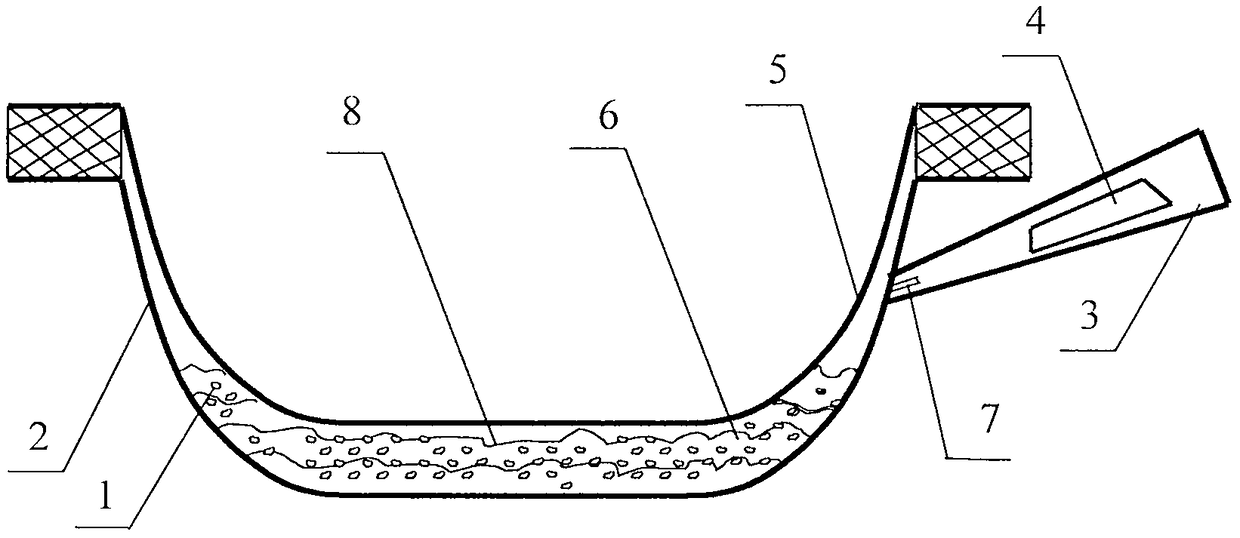

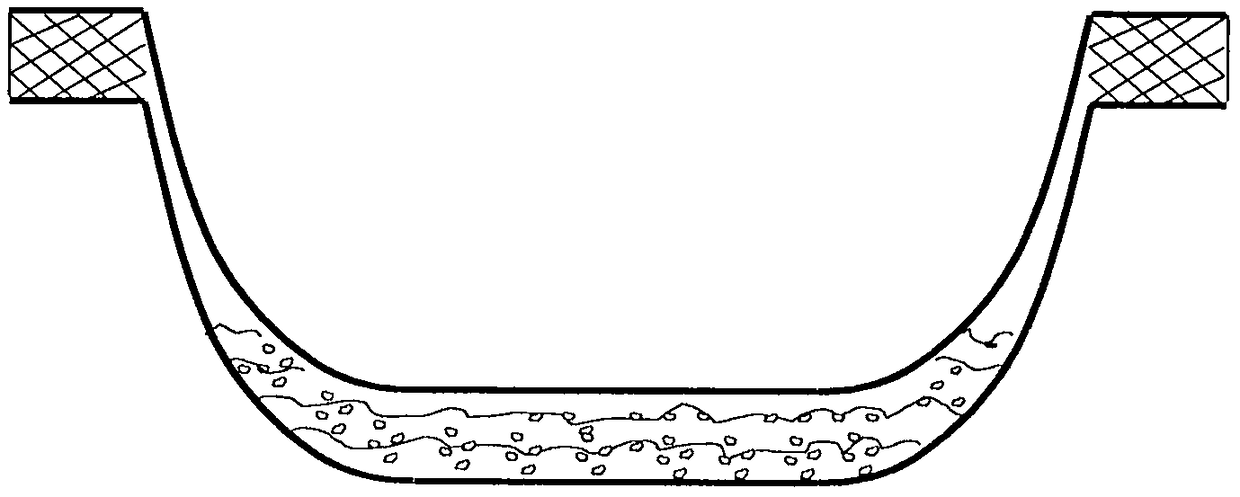

[0015] Specific embodiment 1, in conjunction with figure 1 , 2 and image 3 Specifically explaining this embodiment, the high thermal conductivity stainless steel pot includes a pot body, a pot handle, and a pot cover if necessary. The pot body is a double-layer stainless steel sandwich structure. These two layers of stainless steel plates are molded to form the upper pot body 5 and the lower pot body 2 respectively, and then the upper and lower pot bodies are welded together along the edge of the pot by welding. At the same time, the vacuum pumping pipeline 7 is reserved on the welding of the lower pot body 2 for leak detection, and the double-layer stainless steel interlayer structure is guaranteed to be in a sealed state, and the oil and dust are cleaned and polished for later use.

[0016] For the preparation of the molten salt heat conductor, the solid aluminum chloride+sodium chloride+potassium chloride molten salt product with a melting point of about 100°C is selecte...

specific Embodiment 2

[0019] Specific embodiment 2, in conjunction with figure 2 , image 3 Specifically explaining this embodiment, the high thermal conductivity stainless steel pot includes a pot body, a pot handle, and a pot cover if necessary. The pot body is a double-layer stainless steel sandwich structure. The two layers of stainless steel plates are molded to form the upper pot body 5 and the lower pot body 2 respectively, and then the upper pot body 5 and the handle 3 are connected by riveting, and then the Clean oil and dust, polish and dry before use. Squeeze a barbed wire 8 slightly smaller than the lower pot body with a mold, remove rust and clean oil stains, dust, polish and dry it for later use.

[0020] Select the solid sodium nitrate+potassium nitrate+sodium nitrite molten salt product with a melting point of about 100°C, and melt it for use. Assemble the upper pot body 5 and the lower pot body 2, put the barbed wire 8 into the interlayer, weld the edge part of the lower pot bo...

specific Embodiment 3

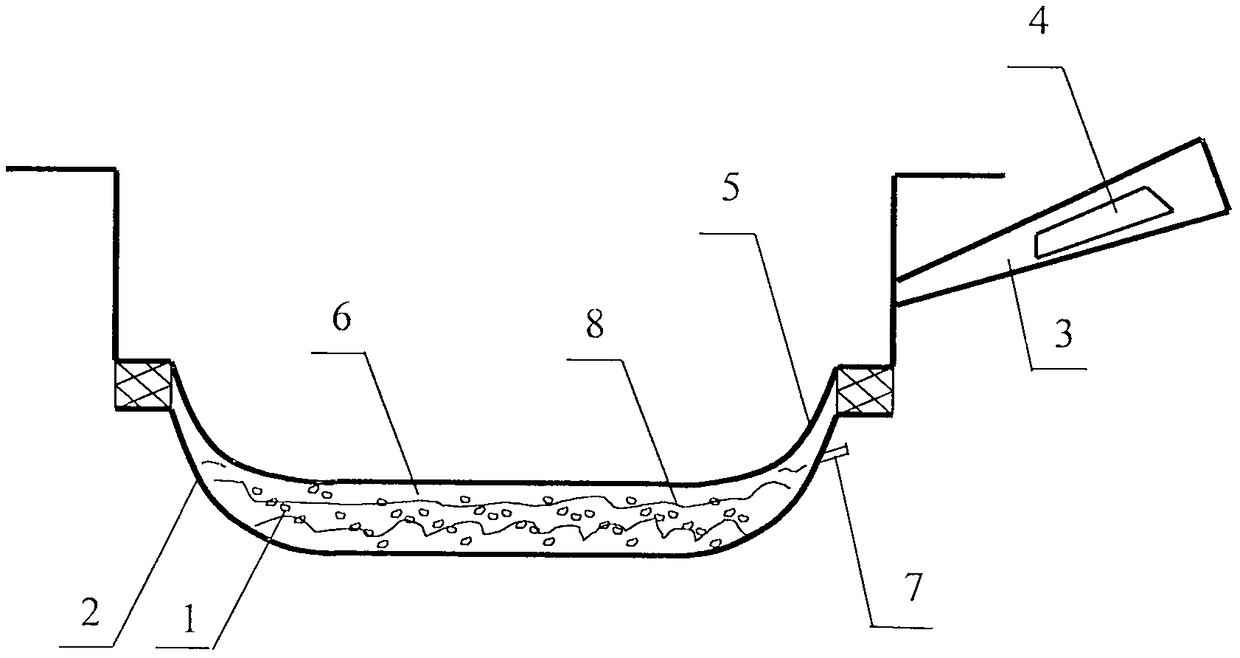

[0023] Specific embodiment 3, electric rice cooker uses high thermal conductivity stainless steel liner pot body. The pot body is a double-layer stainless steel sandwich structure. These two layers of stainless steel plates are molded to form the upper pot body 5 and the lower pot body 2 respectively, and then the oil and dust are cleaned and polished for use.

[0024] For the preparation of the molten salt heat conductor 6, solid aluminum chloride+sodium chloride+potassium chloride molten salt products with a melting point of about 100° C. are selected, and after melting, 40-mesh aluminum powder with a weight ratio of 2% is added, and The 40-mesh iron powder with 10% by weight is used as the sacrificial anode 1 and the ferromagnetic material 8 to become the molten salt heat conductor 6 . Pour the melted molten salt heat conductor 6 into a mold similar to the shape and volume of the interlayer gap of the pot body. The volume of the molten salt heat conductor 6 is about 50% of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com