A resin grinding wheel for grinding cadmium zinc telluride wafer, its preparation method and application

A technology of cadmium zinc telluride wafer and resin grinding wheel, which is applied in grinding/polishing equipment, grinding device, abrasives, etc., can solve the problems of easy inlaying of particles, slow efficiency, and inability to be removed by polishing, etc. Good inlay and surface texture consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

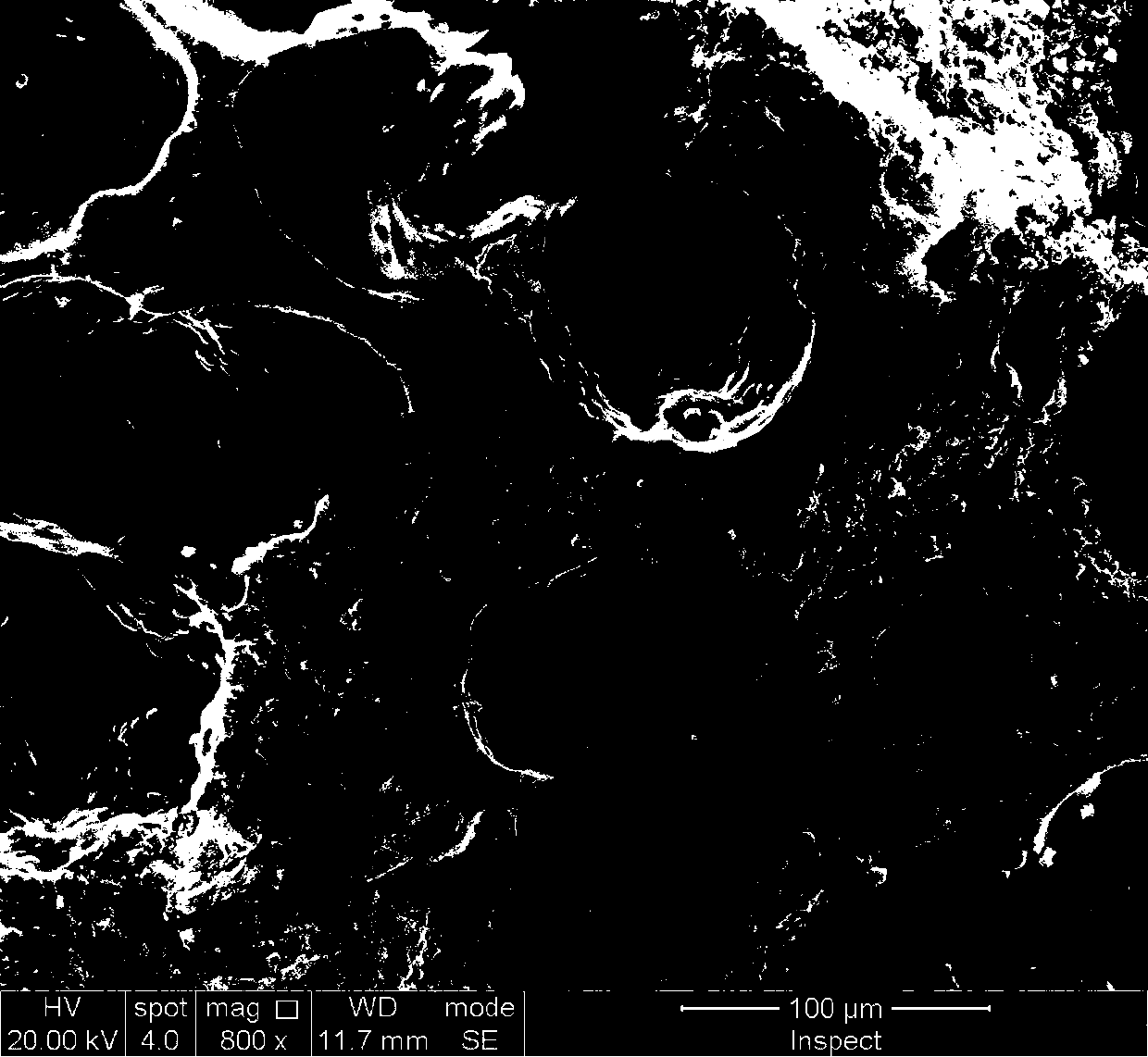

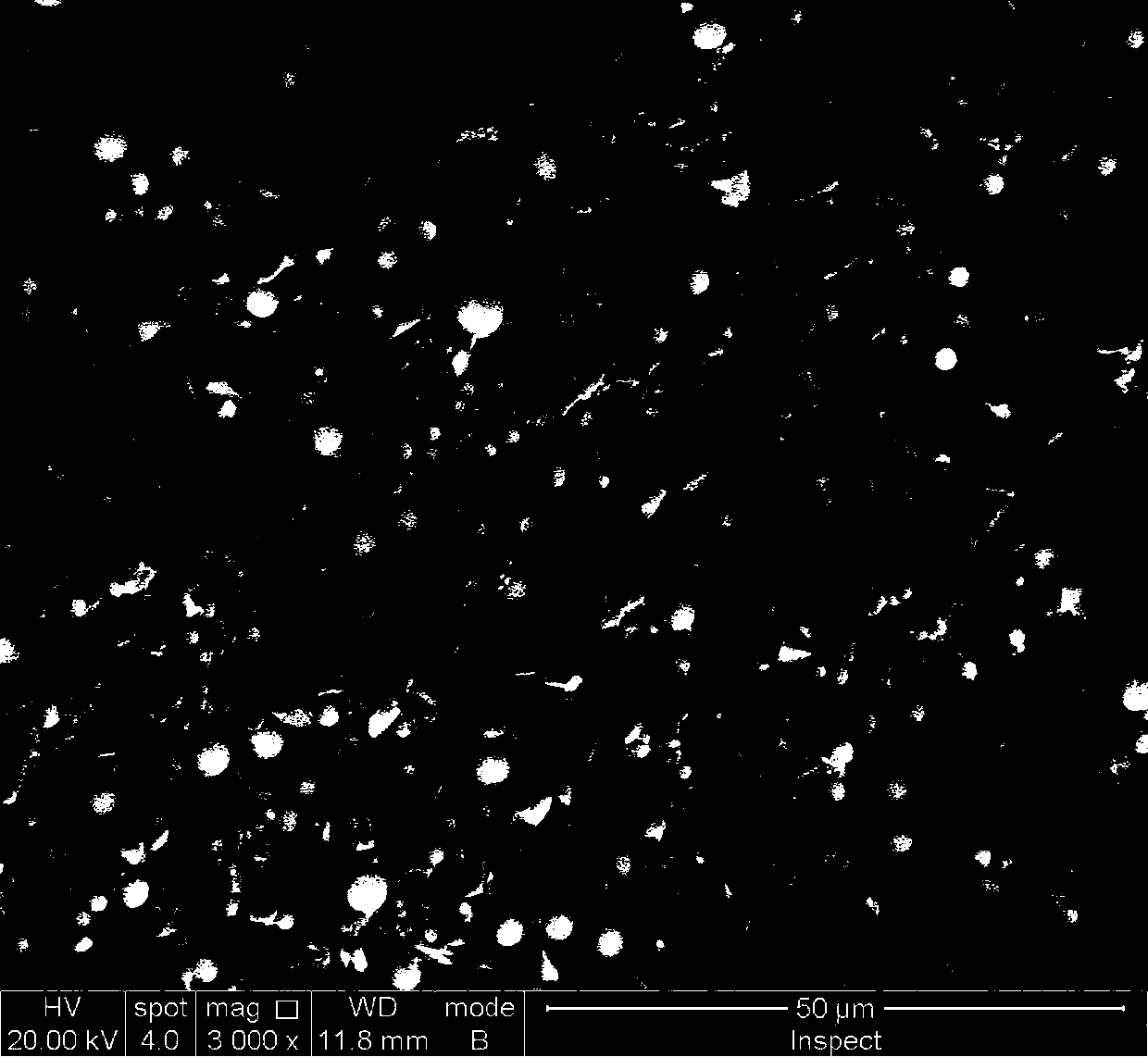

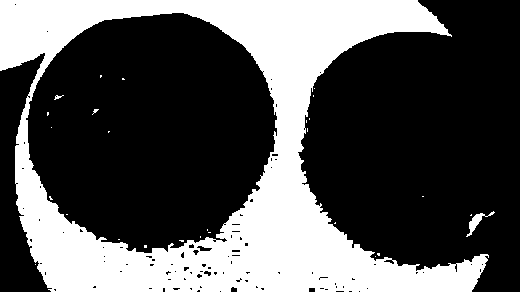

[0030] A method for preparing a resin grinding wheel for grinding cadmium zinc telluride wafers, the resin grinding wheel is composed of the following raw materials in parts by volume: 12 parts of diamond with a particle size of 4 μm; 1 part of pore-forming agent; 3 parts of silicon carbide, The particle size is 2 μm; 8 parts of coupling agent; 15 parts of spherical silica with a hollow structure, the model is d01, and the median value is 0.9 μm; 15 parts of phenolic resin; specifically include the following steps:

[0031] (1) Pass the pore-forming agent through a 350-mesh sieve for 3 times before use; the phenolic resin is ball-milled with a liquid nitrogen ball mill for 120 hours and then pass through a 350-mesh sieve once for use; pass the silicon carbide and hollow spherical silica through a 280-mesh sieve respectively for 3 Mix after the second time to get mixed powder I;

[0032] (2) Treat the diamond surface with NaOH solution (mass fraction: 10%) at 90°C for 120 minut...

Embodiment 2

[0036] The difference between the method of this example and Example 1 is that in the grinding wheel formula, there are 19 parts of diamond with a particle size of 6 μm; 2 parts of pore-forming agent; 2 parts of silicon carbide; 5 parts of coupling agent; 8 parts of spherical silica 12 parts of phenolic resin;

[0037] Preparation method, the condition of hot alkali treatment in step (2) is KOH solution at 80°C (mass fraction is 40%), step (3) mix powder III and corundum ceramic balls for 2 hours, check under a microscope after ball milling For the uniformity of the mixture, 8 places are randomly selected to detect whether there are bright spots and uneven mixing.

Embodiment 3

[0039] The difference between the method of this embodiment and Example 1 is that in the grinding wheel formula, 10 parts of diamond; 0.5 parts of pore-forming agent; 2 parts of silicon carbide; 5 parts of coupling agent; 8 parts of spherical silica; 12 parts of phenolic resin share;

[0040] The preparation method, the ball milling time of phenolic resin in step (1) is 72h, the hot alkali treatment time in step (2) is 60min; the volume of acetone added is 300mL, and the ultrasonic treatment time is 15min; the weight of the mixed powder III and corundum ceramic balls in step (3) The ratio is 3:1; in step (4), the initial temperature is 180°C, the initial pressure is 1.8Mpa, keep the constant temperature and pressure for 1min, increase the pressure to 5.8Mpa, deflate 3 times, and hold the heat for 60min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com