Treatment method for acrylonitrile wastewater

A technology for the treatment of acrylonitrile wastewater, which is applied in water/sewage treatment, natural water treatment, flotation water/sewage treatment, etc., and can solve problems such as long start-up time, increased cost of treatment chemicals, and increased ion concentration of wastewater. Achieve the effects of strong impact resistance to wastewater concentration fluctuations, support for sustainable development, and considerable economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

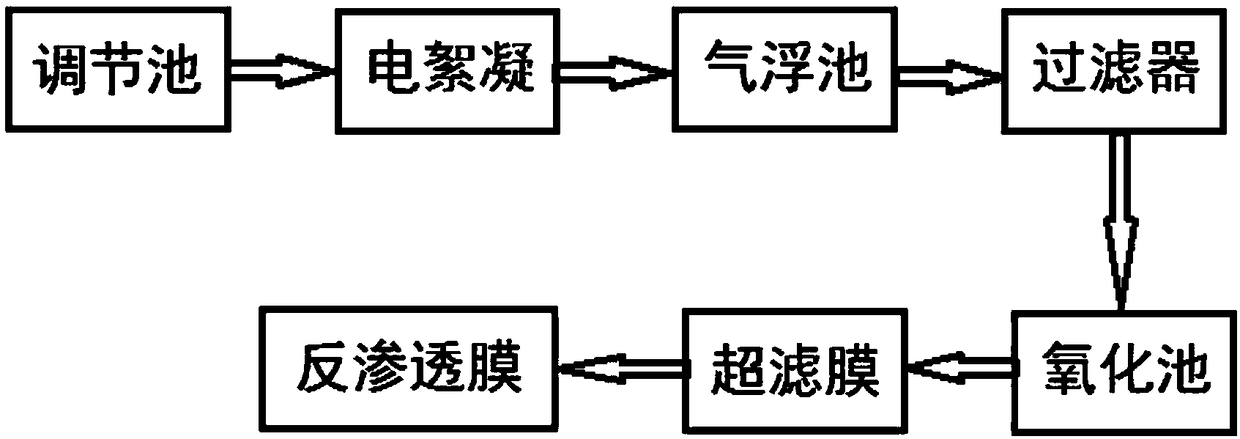

[0036] See figure 1 . A method for treating acrylonitrile wastewater, including the following steps:

[0037] (1) The treated acrylonitrile wastewater is the wastewater produced during the process of propylene ammoxidation to produce acrylonitrile. The main pollutants and concentration ranges in the wastewater are: COD: 1200~3000mg / L; TKN: 200~500mg / L; NH3 -N: 100~250mg / L; TCN: 30~100mg / L.

[0038] The acrylonitrile wastewater is adjusted to pH 6.5 with sulfuric acid or sodium hydroxide and then sent to an adjustment tank equipped with a paddle agitator or jet agitator, and the wastewater is homogenized and uniformly mixed. The wastewater stays in the adjustment tank At least 4 hours.

[0039] (2) The waste water after the uniformity and quantity adjustment of the adjustment tank is sent to the electro-flocculation device for adjustment treatment: the anode of the electro-flocculation device is a rod-shaped material made of aluminum, and the cathode of the electro-flocculation dev...

Embodiment 2

[0050] Follow figure 1 . A method for treating acrylonitrile wastewater, including the following steps:

[0051] (1) The treated acrylonitrile wastewater is the wastewater generated during the process of propylene ammoxidation to produce acrylonitrile (same as Example 1).

[0052] The acrylonitrile wastewater is adjusted to pH 8.5 with sulfuric acid or sodium hydroxide, and then sent to an adjustment tank equipped with a paddle agitator or jet agitator, and the wastewater is homogenized and uniformly mixed. The wastewater stays in the adjustment tank At least 4 hours.

[0053] (2) The waste water after the uniformity and quantity adjustment of the adjustment tank is sent to the electro-flocculation device for adjustment treatment: the anode of the electro-flocculation device is a plate material made of iron, and the cathode of the electro-flocculation device is made of iron For plate-shaped materials, the concentration range of iron ions produced by the electric flocculation devic...

Embodiment 3

[0061] See you again figure 1 . A method for treating acrylonitrile wastewater, including the following steps:

[0062] (1) The treated acrylonitrile wastewater is the wastewater generated during the process of propylene ammoxidation to produce acrylonitrile (same as Example 1).

[0063] The acrylonitrile wastewater is adjusted to pH 7.5 with sulfuric acid or sodium hydroxide and then sent to an adjustment tank equipped with a paddle stirrer or jet agitator, and the wastewater is homogenized and uniformly mixed. The wastewater stays in the adjustment tank At least 4 hours.

[0064] (2) The waste water after the uniformity and quantity adjustment of the conditioning tank is sent to the electro-flocculation device for adjustment treatment: the anode of the electro-flocculation device is a plate material made of aluminum, and the cathode of the electro-flocculation device is made of carbon Rod-shaped material, the concentration range of aluminum ions produced by the electric floccula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Filter pore size | aaaaa | aaaaa |

| Recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com