A kind of preparation method of positive electrode material of lithium ion battery and precursor thereof

A technology for lithium-ion batteries and positive electrode materials, applied in battery electrodes, secondary batteries, chemical instruments and methods, etc., can solve the problems of narrow particle size distribution of precursors, low compaction density of positive electrode materials, and low yield of positive electrode materials. Achieve the effects of being suitable for large-scale industrial production, avoiding low compaction density, and ensuring synthesis stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

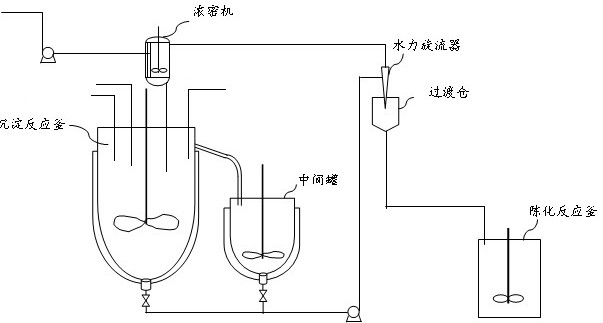

[0045] Dissolve nickel sulfate, cobalt sulfate, and manganese sulfate according to the metal molar ratio of 85:10:5 to obtain a 1.5mol / L nickel-cobalt-manganese mixed salt solution; dissolve sodium hydroxide into an alkali solution with a concentration of 6mol / L as Precipitating agent: Dissolve ammonia water into a complexing agent solution with a concentration of 6mol / L.

[0046] The nickel-cobalt-manganese mixed salt solution, the alkali solution and the complexing agent solution are respectively fed into the 5m with bottom liquid and overflow pipe through their respective liquid inlet pipes. 3 Continuous reaction is carried out in the precipitation reactor, nitrogen protection is introduced during the reaction process, the flow rate of nickel-cobalt-manganese mixed salt solution is controlled to be 200L / h, the flow rate of complexing agent solution is 40L / h, and the stirring speed is maintained at 110 rpm. Constant, the reaction temperature is 50°C, and the reaction pH is 1...

Embodiment 2

[0053] Dissolve nickel nitrate and cobalt nitrate according to the metal molar ratio of 9:1 to obtain a 1mol / L nickel-cobalt mixed salt solution; mix aluminum nitrate and sodium hydroxide according to a molar ratio of 1:5 to obtain an aluminum ion concentration of 0.3mol / L aluminum solution; dissolving zirconium nitrate into a zirconium nitrate solution with a concentration of 0.05mol / L; dissolving sodium hydroxide into an alkali solution with a concentration of 4mol / L as a precipitating agent; mixture solution.

[0054] The nickel-cobalt mixed salt solution, aluminum solution, zirconium nitrate solution, alkali solution, and complexing agent solution are respectively fed into the 5m tank with bottom liquid and overflow pipe through their respective liquid inlet pipes. 3 The continuous reaction is carried out in the precipitation reactor, the flow rate of nickel-cobalt mixed salt solution is 155L / h, the flow rate of aluminum solution is 16L / h, the flow rate of zirconium nitrat...

Embodiment 3

[0059] Dissolve nickel sulfate, cobalt chloride, and manganese chloride according to the metal molar ratio of 6:2:2 to obtain a 2.5mol / L nickel-cobalt-manganese mixed salt solution; dissolve lanthanum nitrate into lanthanum nitrate with a concentration of 0.05mol / L solution; the TiO 2 The nanopowder was formulated into TiO with a concentration of 0.1mol / L 2 Suspension: Dissolve sodium hydroxide into an alkali solution with a concentration of 10mol / L; dissolve ammonia water into a complexing agent solution with a concentration of 12mol / L.

[0060] Mix nickel-cobalt-manganese salt solution, lanthanum nitrate solution, TiO 2Suspension liquid, alkali solution, and complexing agent solution flow through their respective liquid inlet pipes and flow into the 5m pipe with bottom liquid and overflow pipe. 3 The continuous reaction is carried out in the precipitation reactor, nitrogen protection is introduced during the reaction process, the flow rate of the nickel-cobalt-manganese mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com