Schottky diode device

A Schottky diode and Schottky metal technology, applied in semiconductor devices, electrical components, circuits, etc., can solve problems such as surface breakdown, increase in forward conduction loss, and increase in drift region doping concentration and drift region thickness. , to achieve uniform electric field distribution, reduce conduction loss, and improve the effect of forward conduction voltage drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

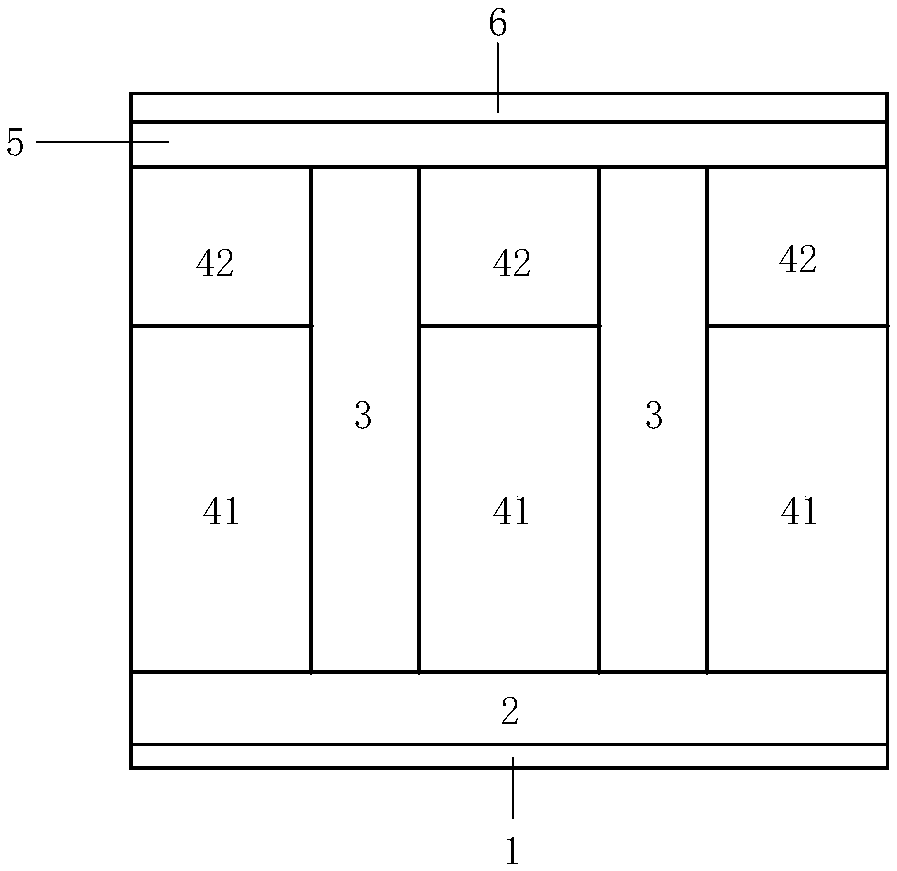

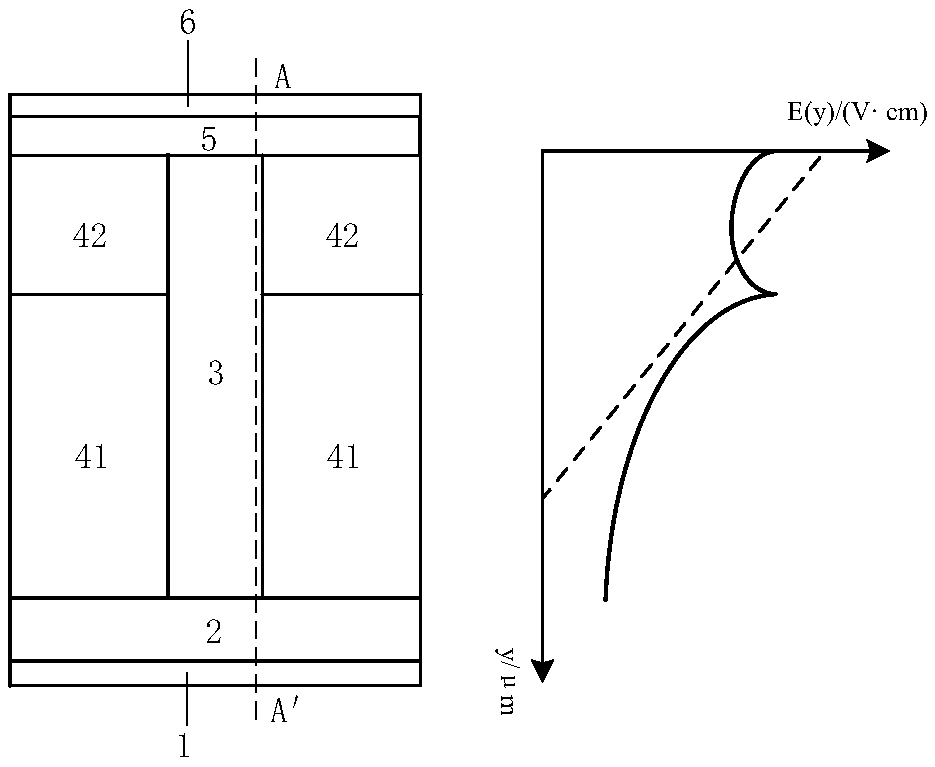

[0022] This embodiment provides a Schottky diode, such as figure 1 As shown, its structure includes a metallized cathode 1, an N+ semiconductor substrate 2, an N-type semiconductor nanowire array, a Schottky metal 5, and a metallized anode 6 arranged sequentially from bottom to top, and is characterized in that: the N-type The semiconductor nanowire array is composed of N-type semiconductor nanowires 3 that are independent of each other and do not contact each other. In this implementation, the diameter of the N-type semiconductor nanowires 3 ranges from 10nm to 1000nm; a composite insulating medium layer is arranged between the N-type semiconductor nanowire arrays 4; the composite insulating dielectric layer 4 is formed by stacking a first insulating dielectric layer 41 and a second insulating dielectric layer 42 from bottom to top, and the dielectric constant of the first insulating dielectric layer 41 is smaller than that of the second insulating dielectric layer The dielec...

Embodiment 2

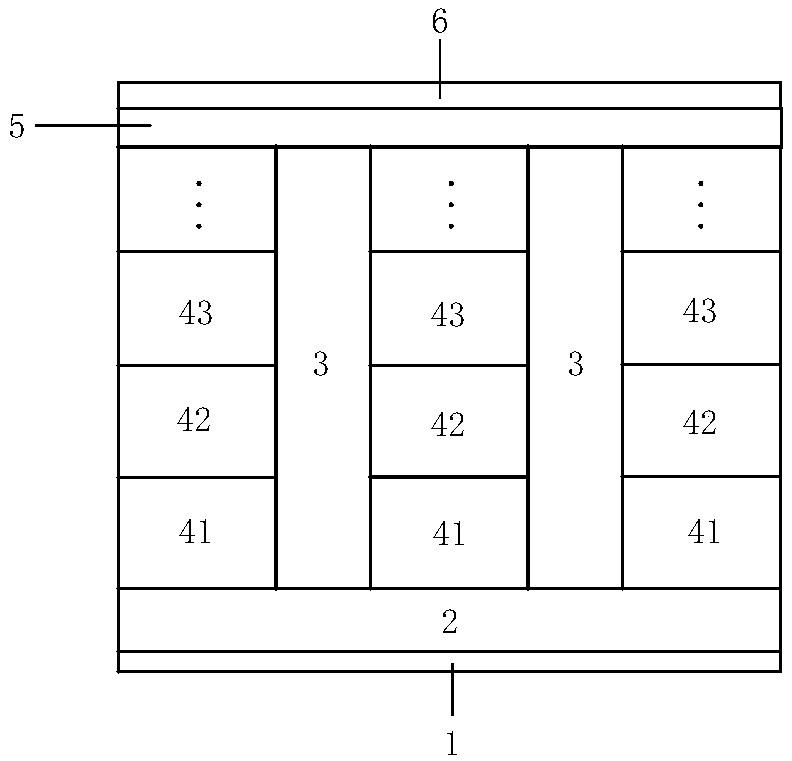

[0026] The difference between this embodiment and Embodiment 1 is that the composite insulating dielectric layer includes multiple insulating dielectric layers such as a first insulating dielectric layer 41, a second insulating dielectric layer 42, a third insulating dielectric layer 43, etc., and multiple insulating dielectric layers The dielectric constant of the dielectric layer decreases sequentially from top to bottom, and the rest of the structure is the same as that of Embodiment 1.

[0027] In this embodiment, since a plurality of insulating dielectric layers are provided, the electric field distribution inside the N-type semiconductor nanowire can be made more uniform, the contradictory relationship between the breakdown voltage of the Schottky diode and the forward conduction voltage drop can be further improved, and the conduction of the device can be reduced. loss.

[0028] Figure 4 to Figure 6 Three-dimensional schematic diagrams of Schottky diodes with differen...

Embodiment 3

[0030] The present invention provides the manufacturing technological process of silicon nanowire Schottky diode as shown in embodiment 1, and main technological step is as follows:

[0031] Step 1: Monocrystalline silicon substrate preparation and semiconductor nanowire 3 growth:

[0032] Such as Figure 7 As shown, select N+ single crystal silicon as the substrate material, use a mask to define the region of N-type semiconductor nanowire 3, partially expose the surface of the single crystal silicon substrate, and then grow on the surface of this region by selective vapor phase epitaxy (VPE) N-type semiconductor nanowires 3 that are independent of each other and do not contact each other are formed to form a semiconductor nanowire array with a certain arrangement;

[0033] Step 2: depositing the first insulating dielectric layer 41:

[0034] Such as Figure 8 As shown, after forming the array of N-type semiconductor nanowires 3, a first insulating dielectric layer 41 is de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com