Preparation method of microorganism desilting agent

A technology of dredging agent and microorganism, which is applied in the field of preparation of microbial dredging agent, can solve the problems that it is difficult to play the role of sediment dredging and water purification, it is easy to lose with the water flow, and the microbial dredging agent cannot sink to the bottom, etc., to achieve high Physical and chemical adsorption performance, improvement of stability performance, effect of improvement of adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

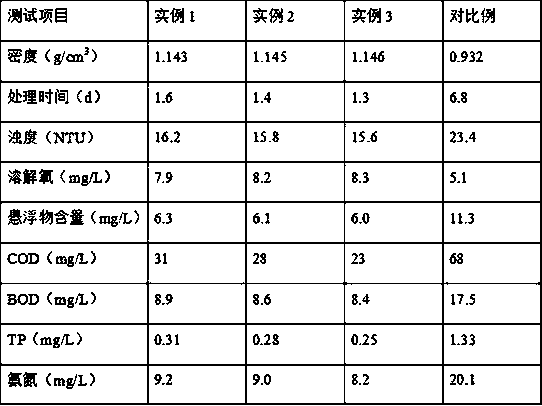

Examples

example 1

[0026]Mix sodium metaaluminate, urea and deionized water at a mass ratio of 1:2:10 and put them into a beaker to obtain a mixed solution. Heat the mixed solution to 70°C, and then add 25% of the mixed solution dropwise to the beaker. Orthosilicic acid, heat preservation and stirring for 2 hours to obtain a prefabricated solution; mix the above prefabricated solution with sodium hexametaphosphate at a mass ratio of 15:1 and move it into a high-pressure hydrothermal kettle, and seal the high-pressure hydrothermal kettle under a pressure of 2.6MPa Heat up to 220°C, perform hydrothermal reaction for 20 hours, filter and separate the reaction filter residue after the hydrothermal reaction is completed, and obtain the modified zeolite after natural drying; mix the above-mentioned modified zeolite with calcium chloride and 30% by weight Mix the hydrogen peroxide solution in a mass ratio of 1:7:25 and put it into a beaker, stir and mix with a magnetic stirrer at a speed of 200r / min for...

example 2

[0028] Mix sodium metaaluminate, urea and deionized water at a mass ratio of 1:2:10 and put them into a beaker to obtain a mixed solution. Heat the mixed solution to 75°C, and then add 25% of the mixed solution dropwise to the beaker. Orthosilicic acid, heat preservation and stirring for 2 hours to obtain the prefabricated solution; mix the above prefabricated solution with sodium hexametaphosphate at a mass ratio of 15:1 and move it into a high-pressure hydrothermal kettle, and seal the high-pressure hydrothermal kettle under a pressure of 2.7MPa Heat up to 235°C, perform hydrothermal reaction for 22 hours, filter and separate to obtain the reaction filter residue after the hydrothermal reaction is completed, and obtain the modified zeolite after natural drying; mix the above-mentioned modified zeolite with calcium chloride and 30% of the supernatant The hydrogen peroxide solution was mixed according to the mass ratio of 1:7:25 and put into a beaker, stirred and mixed with a m...

example 3

[0030] Mix sodium metaaluminate, urea and deionized water at a mass ratio of 1:2:10 and put them into a beaker to obtain a mixed solution. Heat the mixed solution to 80°C, and then add 25% of the mixed solution dropwise to the beaker. Orthosilicic acid, heat preservation and stirring for 3 hours to obtain the prefabricated solution; mix the above prefabricated solution and sodium hexametaphosphate at a mass ratio of 15:1 and move it into a high-pressure hydrothermal kettle, and seal the high-pressure hydrothermal kettle under a pressure of 2.8MPa Heat up to 250°C, perform hydrothermal reaction for 24 hours, filter and separate to obtain the reaction filter residue after the hydrothermal reaction is completed, and obtain the modified zeolite after natural drying; mix the above-mentioned modified zeolite, calcium chloride and 30% supernatant Hydrogen oxide solution is mixed according to the mass ratio of 1:7:25 and put into a beaker, stirred and mixed with a magnetic stirrer at a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com