Method for SPME (solid phase micro-extraction)-MS (mass spectrometry) combined online enrichment detection of nicotine compounds in tobaccos

A technology for nicotinic compounds and compounds, which is applied in the field of solid-phase microextraction-mass spectrometry online enrichment detection of nicotinic compounds in tobacco, which can solve the problems of affecting the accuracy of inspection results, affecting the performance of mass spectrometry analysis, and the content of target compounds is low. problems, achieve good enrichment performance and selectivity, simplify the pretreatment process, and achieve the effect of small sample volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] First use methanol for 15min, water for 15min, 0.1mol L -1 HCl solution for 30 minutes to wash the whole empty capillary column (with an inner diameter of 150 μm) to remove organic and inorganic impurities remaining on the inner wall of the capillary. Next, feed secondary water until the solution that flows out is basically neutral. Then use 0.1mol L -1 The NaOH solution activates the inner wall of the capillary monolithic column for about 3 hours, then passes through secondary water again to neutrality, and finally passes through methanol for 30 minutes, and blows dry with nitrogen for 30 minutes.

[0031] A mixture of methanol:γ-MAPS=50:50 (v / v) was evenly injected into the activated capillary, and reacted for 24 hours to silanize the inner wall of the capillary. After the silanized capillary column is passed through methanol, the silane reagent is washed away. Blow dry with nitrogen.

[0032] Reaction monomer: NIPAAm (60mg); Cross-linking agent: DVB (80mg), MBAA ...

Embodiment 2

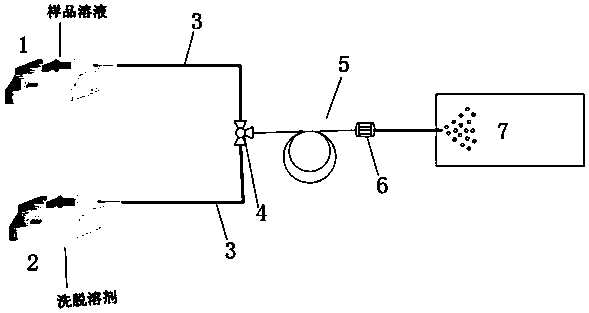

[0034] The poly(NIPAAm-co-DVB-co-MBAA) polymer monolithic column is used in combination with API-MS, and the connection method is as follows figure 2 shown. Two micro-sampling syringe pumps A 1 and B 2 are respectively used as the driving force for the analysis sample and the elution solvent, passing through the PEEK tube 3, the tee tube 4 and the poly(NIPAAm-co-DVB-co-MBAA) polymer monolithic column 5 to link up. Then through a two-way tube 6 and a PEEK tube 3, it is connected to the ESI of the vacuum chamber in the vacuum electrospray-mass spectrometer detector API-M7S. The analyte undergoes sample extraction, elution and other procedures, and finally enters the mass spectrometer for analysis.

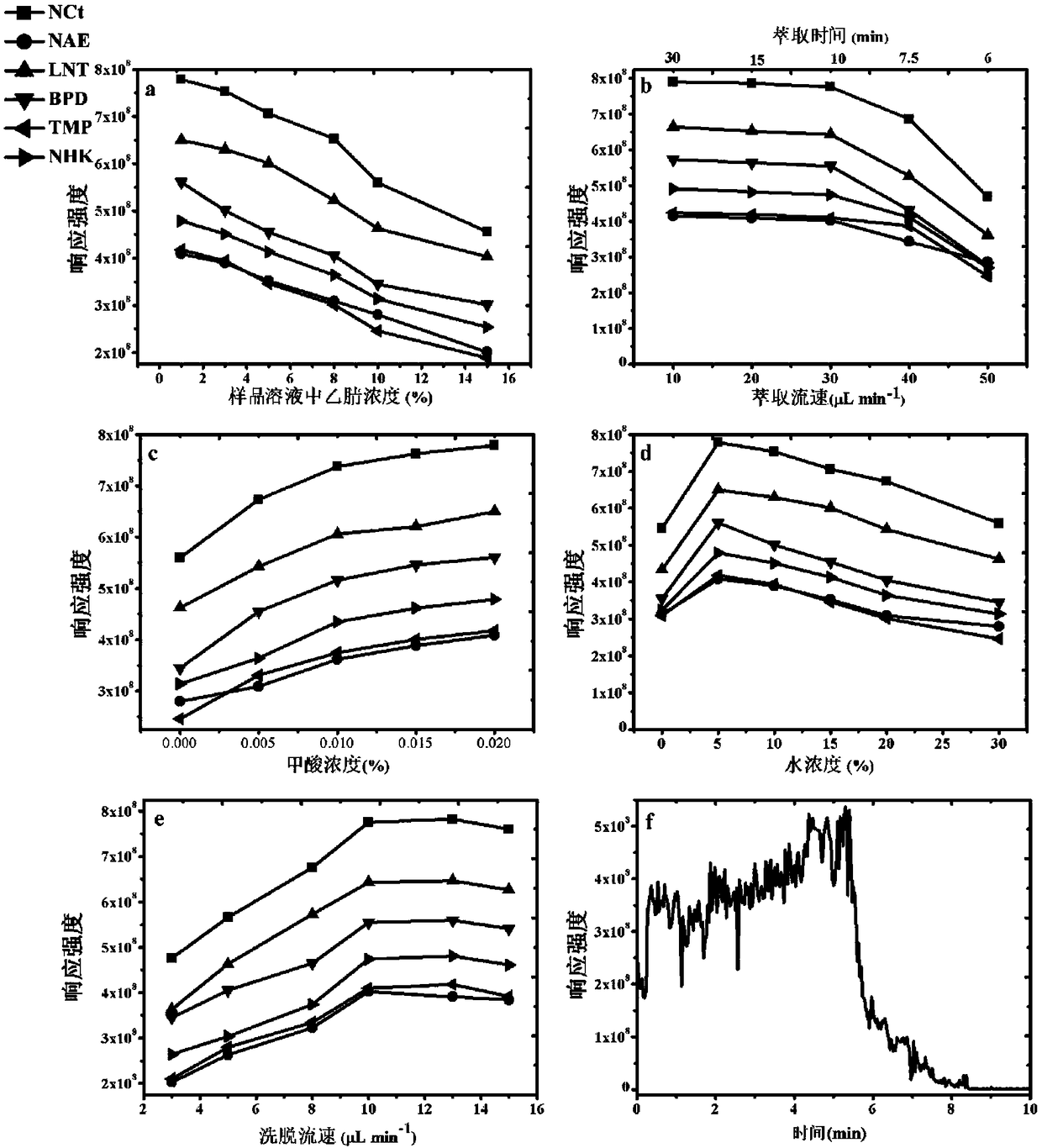

[0035] After condition optimization, the optimal conditions are: the content of acetonitrile (99%, v / v) in the sample, the extraction flow rate (30μLmin -1 ), formic acid concentration (0.01%, v / v), water concentration, elution flow rate, elution time, adopt the following enrichm...

Embodiment 3

[0038] Sample solution: 300 μL; solvent is water: ACN=99:1 (v / v); injection flow rate: 30 μL min -1 ; Extraction time: 10min; Elution solution: ACN: 0.01% formic acid aqueous solution = 95:5 (v / v); Elution flow rate: 10 μ L min -1 ; Elution time: under the condition of 10 minutes, the method is used to detect and analyze six kinds of nicotine compounds in tobacco samples, and the detection range is 1-100 ng / mL, and the detection parameters are shown in Table 1.

[0039] Table 1 Analytical parameters obtained by analyzing six kinds of nicotine compounds by solid-phase microextraction-mass spectrometry in tube

[0040]

[0041] Note: R2 correlation coefficient; RSD relative standard deviation.

[0042] The results in Table 1 show that the detection limit can reach 0.140~0.644ng·mL -1 , the lowest detection amount can reach 1.99~4.06ng·mL -1 , the deviation in the same day is 5.89-6.43%, and the deviation in different days is 10.3-12.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com