Preparation technology of solid-state lithium ion battery

A lithium-ion battery and preparation process technology, which is applied in the field of solid-state lithium-ion battery preparation technology, can solve the problems of difficult preparation process of thin ceramic sheets, poor contact between ceramic sheets and positive and negative electrodes, and low ion conductivity, etc. Application prospects and advantages, excellent electrochemical performance, and the effect of high ionic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

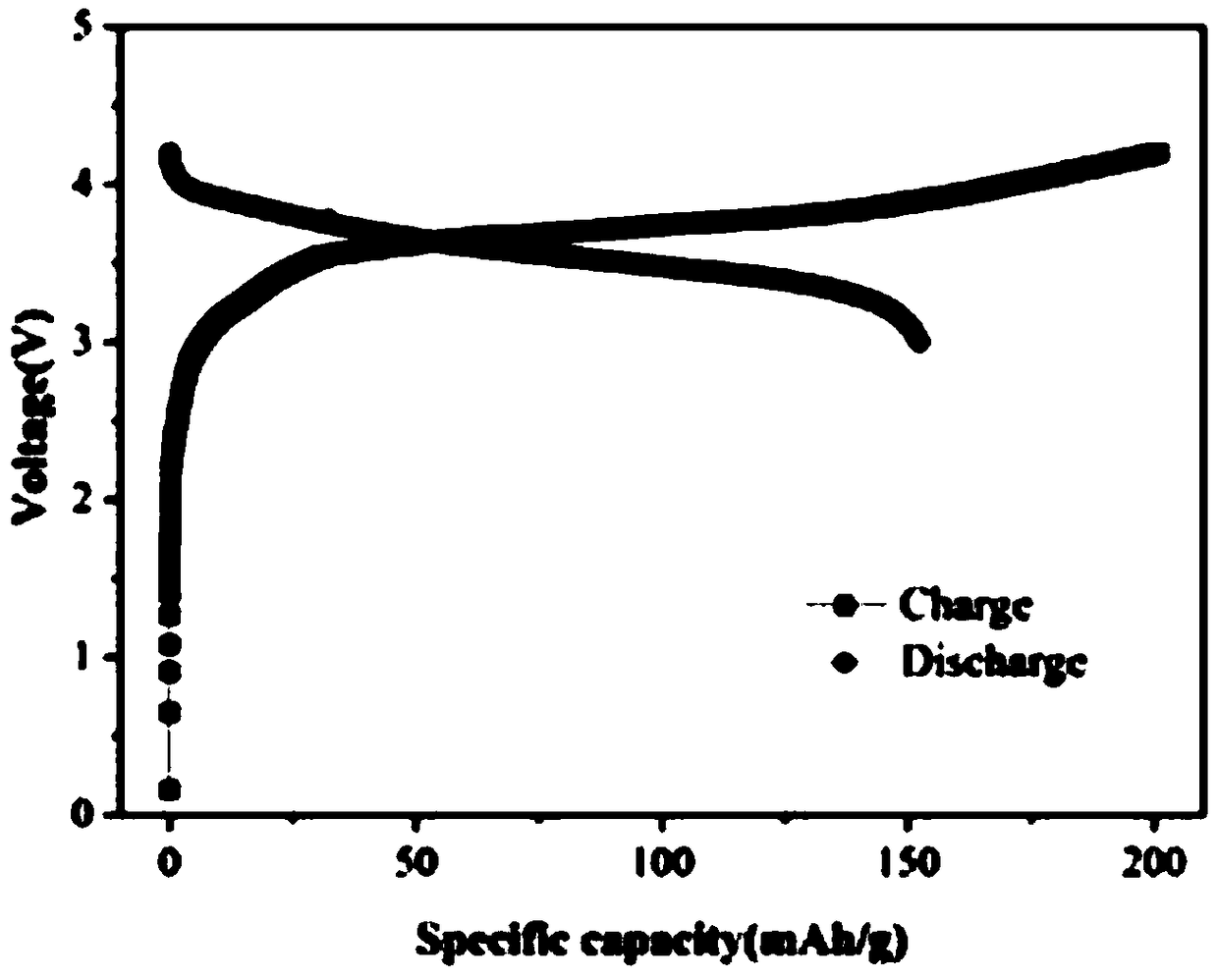

Image

Examples

Embodiment 1

[0019] Such as figure 1 Shown: the preparation technology of a kind of solid-state lithium-ion battery of the present invention, comprises the following steps: Step 1: the lithium lanthanum zirconium oxygen that mass percent is doped with tantalum of 35wt%, the polytetrafluoroethylene emulsion of 5wt% and 10wt% Lithium bistrifluoromethanesulfonylimide was mixed evenly in 50wt% nitrogen methyl pyrrolidone solvent to obtain a coating slurry, which was respectively coated on the surface of the positive electrode sheet and the negative electrode sheet, and dried to obtain an inorganic coating with a coating thickness of 10 μm. Integrated electrode material coated with ceramic electrolyte;

[0020] Step 2: Stir and mix polyether silane with a mass percentage of 50wt%, 40wt% lithium bistrifluoromethanesulfonimide, and 10wt% ethylene carbonate to obtain a polymer solid electrolyte, which is respectively coated on the inorganic ceramic electrolyte On the surface of the electrode, an ...

Embodiment 2

[0024] Such as figure 1 Shown: the preparation technology of a kind of solid-state lithium ion battery of the present invention, comprises the following steps: Step 1: the lithium hexafluorophosphate that mass percent is 45wt% lithium lanthanum titanium oxide, 5wt% polymethyl methacrylate and 20wt% lithium hexafluorophosphate 30wt% nitrogen methyl pyrrolidone solvent is mixed uniformly to obtain a coating slurry, which is respectively coated on the surface of the positive electrode sheet and the negative electrode sheet, and dried to obtain an integrated electrode material coated with an inorganic ceramic electrolyte with a coating thickness of 50 μm;

[0025] Step 2: Stir and mix 40 wt% polymethyl methacrylate, 55 wt% lithium tetrafluoroborate and 15 wt% dimethyl carbonate to obtain a polymer solid electrolyte, which is coated on electrodes coated with inorganic ceramic electrolytes On the surface, an electrode with a double solid electrolyte with a polymer solid electrolyte ...

Embodiment 3

[0029] Such as figure 1 Shown: the preparation technology of a kind of solid-state lithium ion battery of the present invention, comprises the following steps: Step 1: the mass percentage is the lithium lanthanum zirconium oxygen of 20wt%, the polyvinylidene fluoride emulsion of 10wt% and the tetrafluoroethylene of 10wt% Lithium borate is uniformly mixed in 60wt% nitrogen methyl pyrrolidone solvent to obtain a coating slurry, which is respectively coated on the surface of the positive electrode sheet and the negative electrode sheet, and dried to obtain an inorganic ceramic electrolyte-coated integrated electrode with a coating thickness of 100 μm Material;

[0030] Step 2: Stir and mix perfluoropolyether with a mass percentage of 60wt%, 35wt% lithium dioxalate borate, and 5wt% ethyl methyl carbonate to obtain a polymer solid electrolyte, which is coated on the electrode surface coated with an inorganic ceramic electrolyte, Obtain an electrode with a double solid electrolyte ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com