Polyimide thin dielectric film, preparation method and application thereof

A technology of polyimide film and polyimide electricity, which is applied in the field of high-temperature-resistant polyimide dielectric film and its preparation for film capacitors, can solve the problem of low g and achieve high dielectric constant and low dielectric Loss, highlight the effect of heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

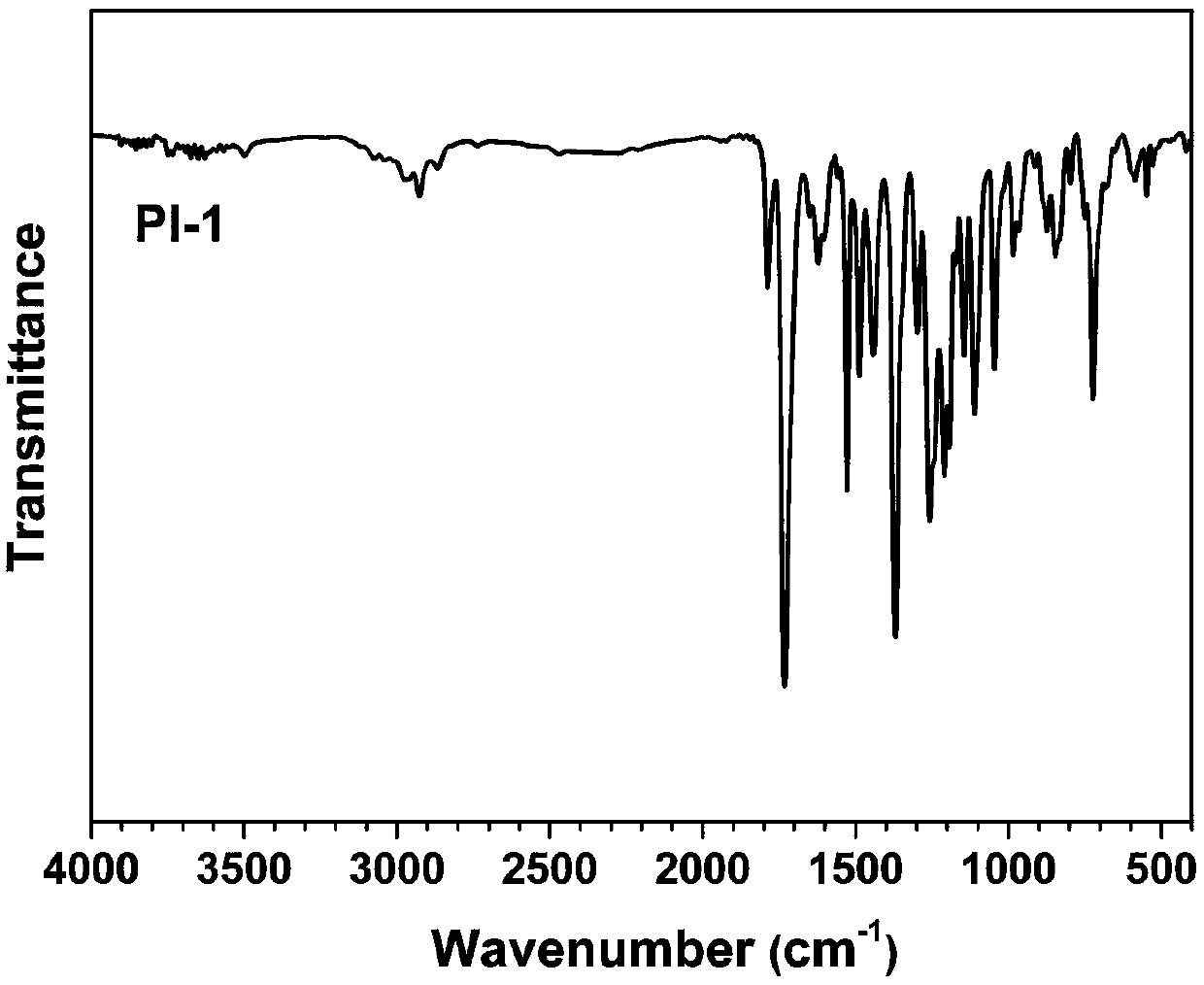

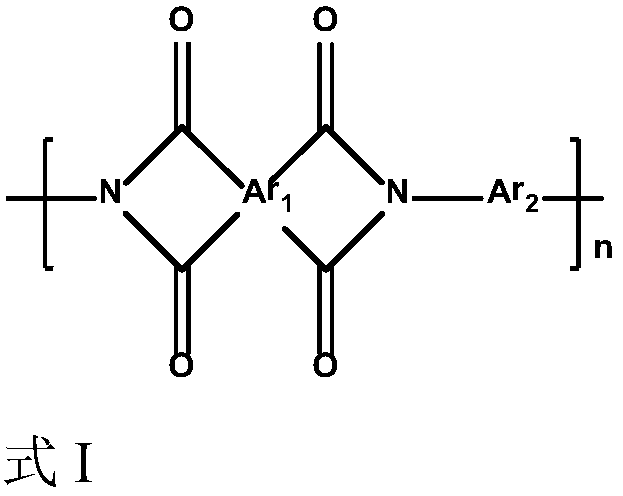

[0044] Embodiment 1, the preparation of polyimide dielectric film

[0045] At room temperature and normal pressure, in a three-neck round-bottomed flask equipped with mechanical stirring and a nitrogen inlet and outlet, add 1.9623 grams of 0.0098 moles of 4,4'-diaminodiphenyl ether and 40.1 grams of N-methylpyrrolidone (NMP), Stir under nitrogen protection until completely dissolved, add 2.4922 grams of 0.01 mole 3,3',4,4'-biphenyltetraacid dianhydride to obtain a homogeneous solution with a solid content of 10wt.%, and continue to react for 6 hours to obtain Polyamic acid solution.

[0046] After the above polyamic acid solution is filtered and vacuum degassed, it is coated on a glass plate with a smooth surface. The temperature is raised in the step of ℃, an imidization reaction occurs, and a polyimide film is obtained. Place the glass plate in deionized water to peel off the film automatically, and dry it in vacuum to obtain a polyimide dielectric film with a thickness of...

Embodiment 2

[0049] Embodiment 2, the preparation of polyimide dielectric film

[0050] At room temperature and normal pressure, in a three-necked round-bottomed flask equipped with mechanical stirring and a nitrogen inlet and outlet, add 1.9826 grams of 0.01 mole 4,4'-diaminodiphenylmethane and 28.8 grams of dimethyl sulfoxide (DMSO), Stir under nitrogen protection until completely dissolved, then add 3.1020 grams of 0.01 mole 3,3',4,4'-diphenyl ether tetraacid dianhydride to obtain a homogeneous solution with a solid content of 15wt.%, and continue the reaction for 8 hours to obtain a polyamic acid solution.

[0051] After the above polyamic acid solution is filtered and vacuum defoamed, it is coated on a silicon wafer with a smooth surface. °C, 250 °C for 1 hour, and 300 °C for 0.5 hour, and the imidization reaction occurred to obtain a polyimide film. The silicon wafer was placed in deionized water to peel off the film automatically, and dried in vacuum to obtain a polyimide dielectr...

Embodiment 3

[0053] Embodiment 3, preparation and characterization of polyimide dielectric film

[0054] At room temperature and normal pressure, in a three-necked round-bottomed flask equipped with mechanical stirring and a nitrogen inlet and outlet, add 3.5571 grams of 0.0095 moles of 1,4-bis(4-aminobenzoic acid) hydroquinone ester and dimethyl sulfoxide ( DMSO) and N,N-dimethylformamide (DMF) mixed solvent 20.3 grams, volume ratio DMSO:DMF=1:1, stirred under nitrogen protection until completely dissolved, added 3.2223 grams of 0.01 mole of 3,3', 4,4'-benzophenonetetraacid dianhydride to obtain a homogeneous solution with a solid content of 25 wt.%, and continue to react for 6 hours to obtain a polyamic acid solution.

[0055] After the above polyamic acid solution is filtered and vacuum degassed, it is coated on a glass plate with a smooth surface. The temperature is raised in the step of ℃, an imidization reaction occurs, and a polyimide film is obtained. Place the glass plate in dei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com