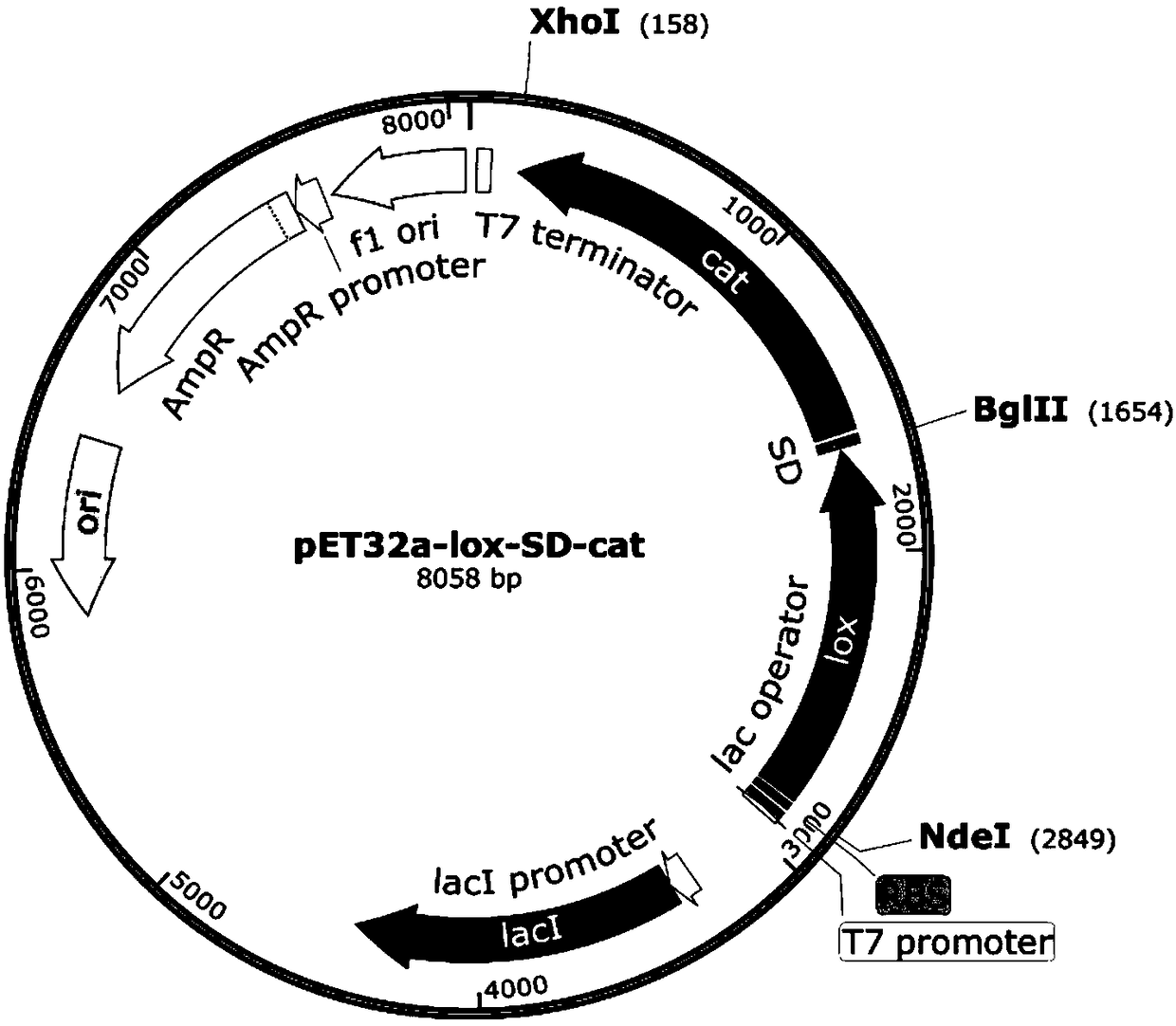

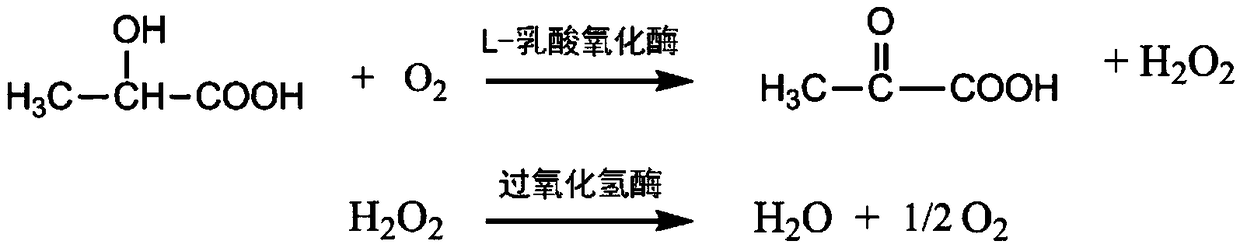

Method for coupling production of sodium pyruvate by co-expressing L-lactate oxidase and hydrogen peroxide

A technology of lactate oxidase and catalase, which is applied in the field of enzyme catalysis, can solve the problems of unsuitability for industrialization, high cost and low yield of enzymatic conversion methods, and achieve the effects of increased yield, simple post-treatment, and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Cultivation of engineering bacteria: Transplant permanent bacteria into the primary medium in a sterile environment, cultivate for 9 hours at a temperature of 37°C and a rotation speed of 220rpm, transfer to the secondary medium after the OD600 reaches 3-4, and then transfer to the secondary medium at a temperature of 37°C. Cultivate at 220rpm for 4-5 hours; then connect it to a fermenter for 37°C cultivation, start feeding when the pH and dissolved oxygen rise, and when the bacterial concentration OD600 reaches 22-28, start to cool down to 30°C, add 0.1mM induction Induced culture with agent IPTG for 12 hours, put in tanks, and collect the bacteria for later use.

[0048] Transformation experiment: 3L 0.2M system transformation was done in a 5L fermenter, the dosage of wet bacteria was 20g / L, the substrate L-sodium lactate was 0.2M, and the content of disodium EDTA was 10mM. Add 60g of the bacteria obtained from fermentation to 1.2L of water, stir well and pour into th...

Embodiment 2

[0051] Cultivation of engineering bacteria: In a sterile environment, transplant permanent bacteria into the primary medium, cultivate at a temperature of 37°C and a rotation speed of 220rpm for 9 hours, and transfer to the secondary medium after the OD600 reaches 3 to 4. Cultivate at 220rpm for 4-5 hours; then connect it to a fermenter for cultivation at 37°C, start feeding when the pH and dissolved oxygen rise, and when the bacterial concentration OD600 reaches 22-28, start to cool down to 30°C, add 0.1mM IPTG to induce culture for 12 Put it in the tank for an hour, and collect the bacteria for later use.

[0052] Transformation experiment: Transform 3L of 0.5M system in a 5L fermenter, the dosage of wet bacteria is 30g / L, the substrate L-sodium lactate is 0.5M, and the content of disodium EDTA is 10mM. Add 90g of wet bacteria to 1.2L of water, stir well and pour into the transformation tank; add 168.8g of L-lactic acid (80%) in total to dilute with water, react with NaOH to...

Embodiment 3

[0055] Cultivation of engineering bacteria: in a sterile environment, inoculate the permanent bacteria in the primary medium, cultivate at a temperature of 37°C and a rotational speed of 220rpm for 9 hours, and transfer to the secondary medium after the OD600 reaches 3-4, and incubate at a temperature of 37°C with a rotational speed of 220 Cultivate at 220rpm for 4-5 hours; then connect to a fermenter for cultivation at 37°C, start feeding when the pH and dissolved oxygen rise, and when the bacterial concentration OD600 reaches 22-28, start to cool down to 30°C, add 0.1mM IPTG to induce cultivation for 12 hours Put it in a tank and collect the bacteria for later use.

[0056] Transformation experiment: Transform 6L of 1.0M system in a 10L fermenter, the dosage of wet bacteria is 40g / L, the substrate L-sodium lactate is 1.0M, and the content of disodium EDTA is 10mM. Add 240g of wet bacteria to 2.4L of water, stir well and pour into the transformation tank; add 675g of L-lactic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com