Immunosorbent for removing inflammatory factors in blood and preparation method thereof

An immunoadsorbent and inflammatory factor technology, applied in the field of biomedicine, can solve the problem of low selectivity, achieve high adsorption performance, avoid non-specific adsorption and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

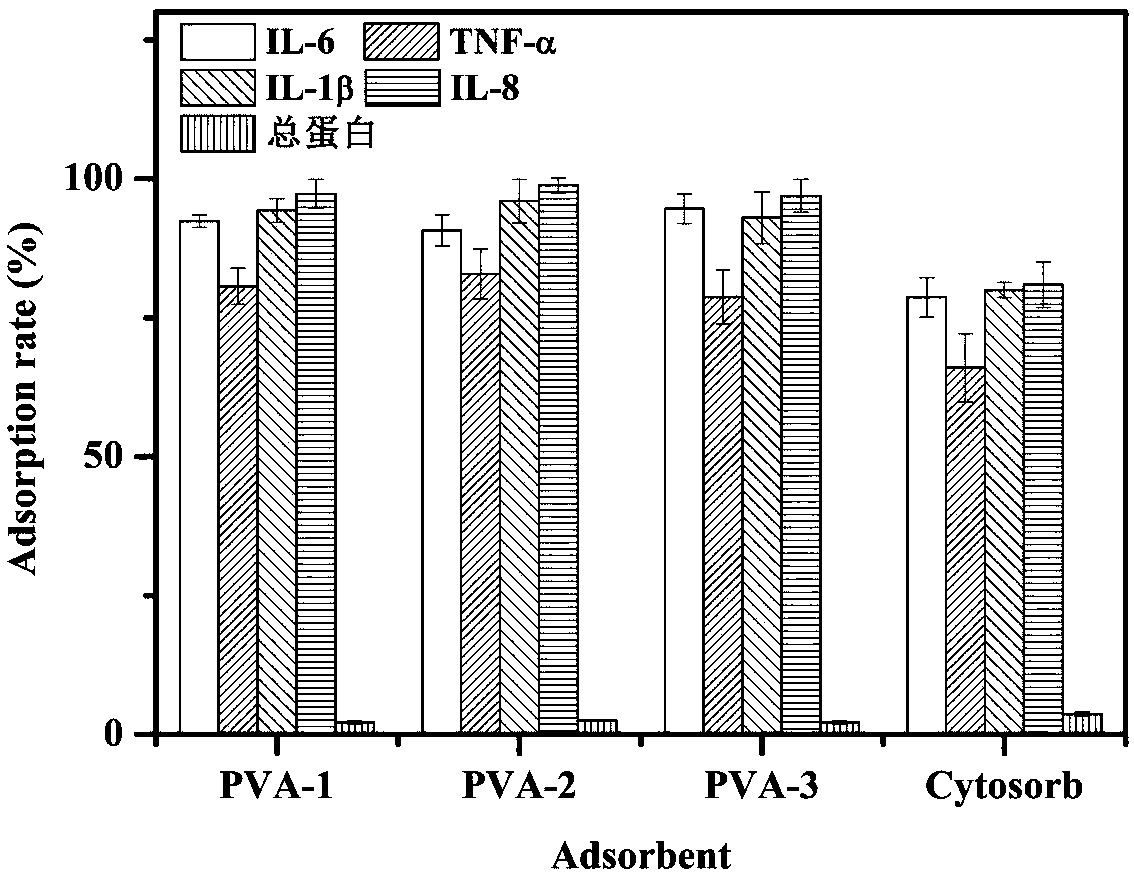

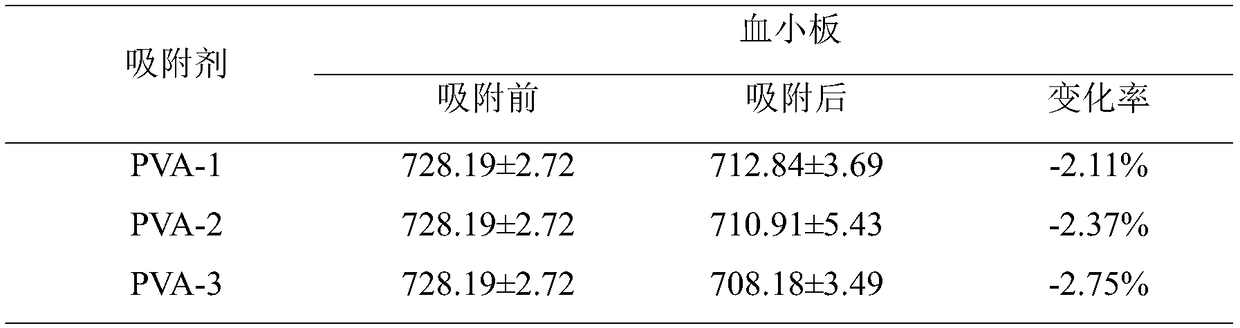

Examples

Embodiment 1

[0023] (1) Preparation of polystyrene microspheres

[0024] Add monomer 53g vinyl acetate and crosslinking agent 10g triallyl isocyanurate into a 250mL beaker and mix well, then add 35.2g ethyl acetate, 35.9g n-heptane, 23.4g n-hexane The alkane and 0.6 g of benzoyl peroxide are stirred to dissolve them. After the dissolution is complete, they are mixed thoroughly to obtain an oil phase. Then the system solution was added to 252mL 2.8% polyvinyl alcohol solution (with 1.2% NaCl), the stirring rate was adjusted to disperse the system into uniform small oil beads, after the temperature was raised to 52°C, after the reaction for 5.5h, Then continue to heat up to 79℃ to react for 3.5h, filter, the reaction system is filtered and washed with hot water after treatment, then extracted with methanol for 16h to remove the porogen, vacuum dried for 36h to obtain white copolymer microspheres and added to 1.2% In the NaOH / methanol solution, the transesterification was carried out at 40°C fo...

Embodiment 2

[0030] (1) Preparation of polystyrene microspheres

[0031] Add monomer 62.6g vinyl acetate and crosslinking agent 17.4g triallyl isocyanurate into a 500mL beaker and mix well, then add 84.5g ethyl acetate, 153.6g n-heptane, 145.9 g n-hexane and 4.64 g of benzoyl peroxide are stirred to dissolve them, and after the dissolution is complete, they are mixed thoroughly to obtain an oil phase. Then the system solution was added to 1299.2mL 0.65% polyvinyl alcohol solution (containing 9.6% NaCl), the stirring rate was adjusted to disperse the system into uniform small oil beads, after the temperature was raised to 59°C, after 3.5 hours of reaction, Then continue to heat up to 72℃ to react for 5h, filter, the reaction system is filtered and washed with hot water after treatment, then extracted with methanol for 28h to remove the porogen, vacuum dried for 24h to obtain white copolymer microspheres and added to 4.9% In NaOH / methanol solution, the transesterification was carried out at 60...

Embodiment 3

[0037] (1) Preparation of polystyrene microspheres

[0038] Add monomer 49.2g vinyl acetate and crosslinking agent 30.8g triallyl isocyanurate into a 500mL beaker and mix well, then add 29.6g ethyl acetate, 118.2g n-heptane, 92.2 g n-hexane and 2.08 g of benzoyl peroxide are stirred to dissolve, and after the dissolution is complete, mix well to obtain an oil phase. Then add the system solution to 740.8 mL of 1.7% polyvinyl alcohol solution (with 5.2% NaCl), adjust the stirring rate to disperse the system into uniform small oil beads. After the temperature is raised to 55°C, the reaction time is 4.5 hours. Then continue to heat up to 76℃ to react for 4.5h, filter, the reaction system is filtered and washed with hot water after treatment, and then extracted with methanol for 36h to remove the porogen, vacuum dried for 12h to obtain white copolymer microspheres and added to 2.6% In the NaOH / methanol solution, the transesterification was carried out at 50°C for 48h, filtered, extra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com