Preparation method and application for high-activity hydrogenation reaction catalyst

A hydrogenation reaction and catalyst technology, which is applied in the preparation of organic compounds, catalysts for physical/chemical processes, organic compounds/hydrides/coordination complex catalysts, etc. High reproducibility, easy storage, and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1. Preparation of polystyrene aldehyde-based microspheres:

[0025] (1) Add 18mL of absolute ethanol, 25mL of deionized water and 2.5g of polyvinylpyrrolidone (PVP) into a three-necked flask equipped with a condenser, and place it in a constant temperature water bath at 70°C, mechanically stir and keep the speed at 315r / min.

[0026] (2) Dissolve 0.1 g of initiator AIBN in 6 mL of styrene to obtain monomeric styrene in which the initiator AIBN is dissolved.

[0027] (3) Add monomer styrene dissolved in initiator AIBN to the system obtained in (1), and add 2.53g (3.0ml) acrolein (C 3 h 4 O), after constant temperature reaction for 7 hours, add hydrochloric acid and increase the temperature of constant temperature water bath to 80°C for 12 hours, after stopping the reaction, wash with ethanol / water and ultrasonic several times, centrifuge and dry to obtain polystyrene aldehyde Ball (PS-CHO).

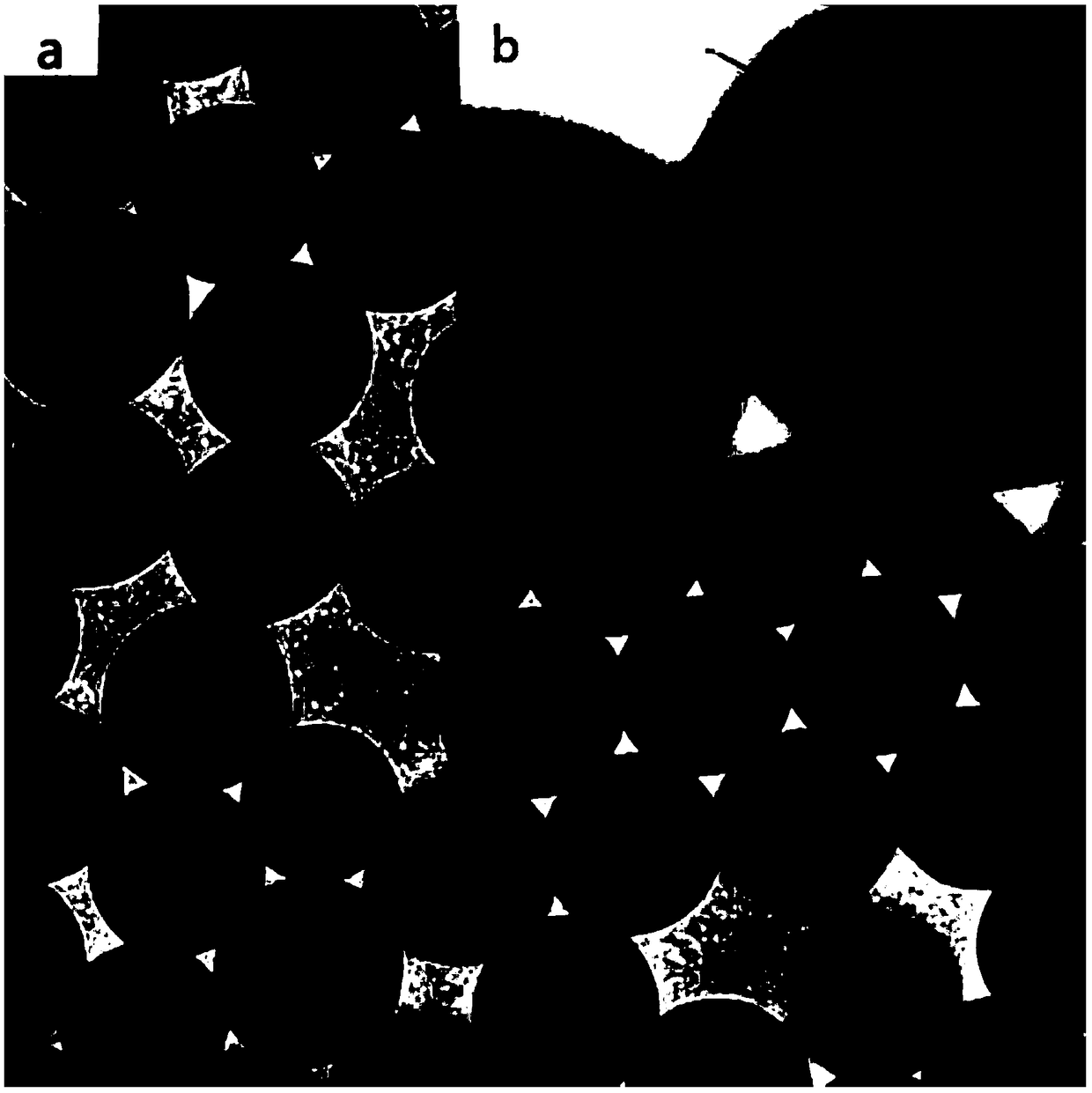

[0028] 2. Preparation of surface-modified palladium nanoparticles (PS-CHO@P...

Embodiment 2、3、4、5

[0036] The same steps as in Example 1 will not be repeated here, only the reaction time for preparing aniline in step 3 is changed, which are 5h, 24h, 48h, and 49h, respectively.

[0037] Other steps are the same as in Example 1.

[0038] Two, embodiment 1-5 test result analysis:

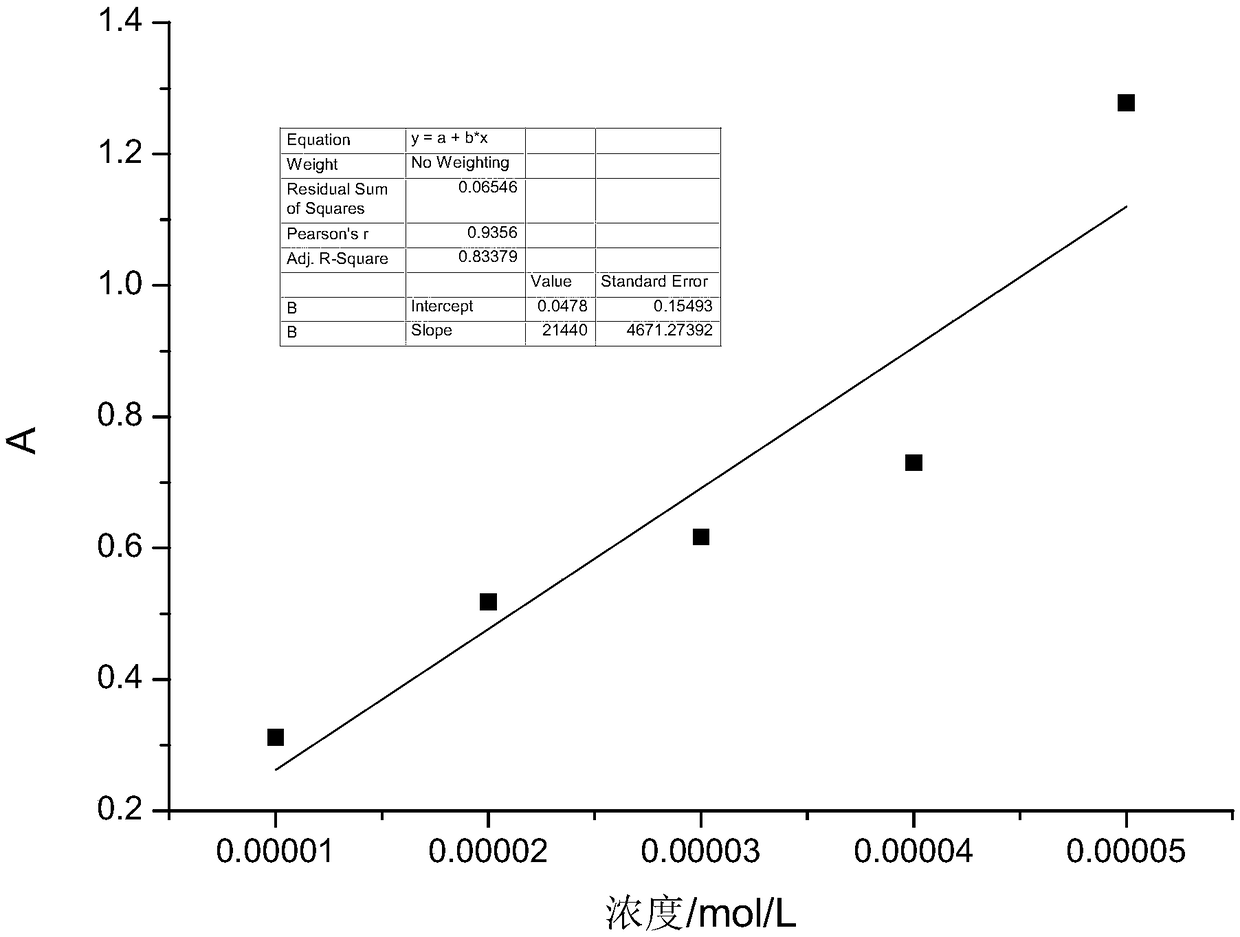

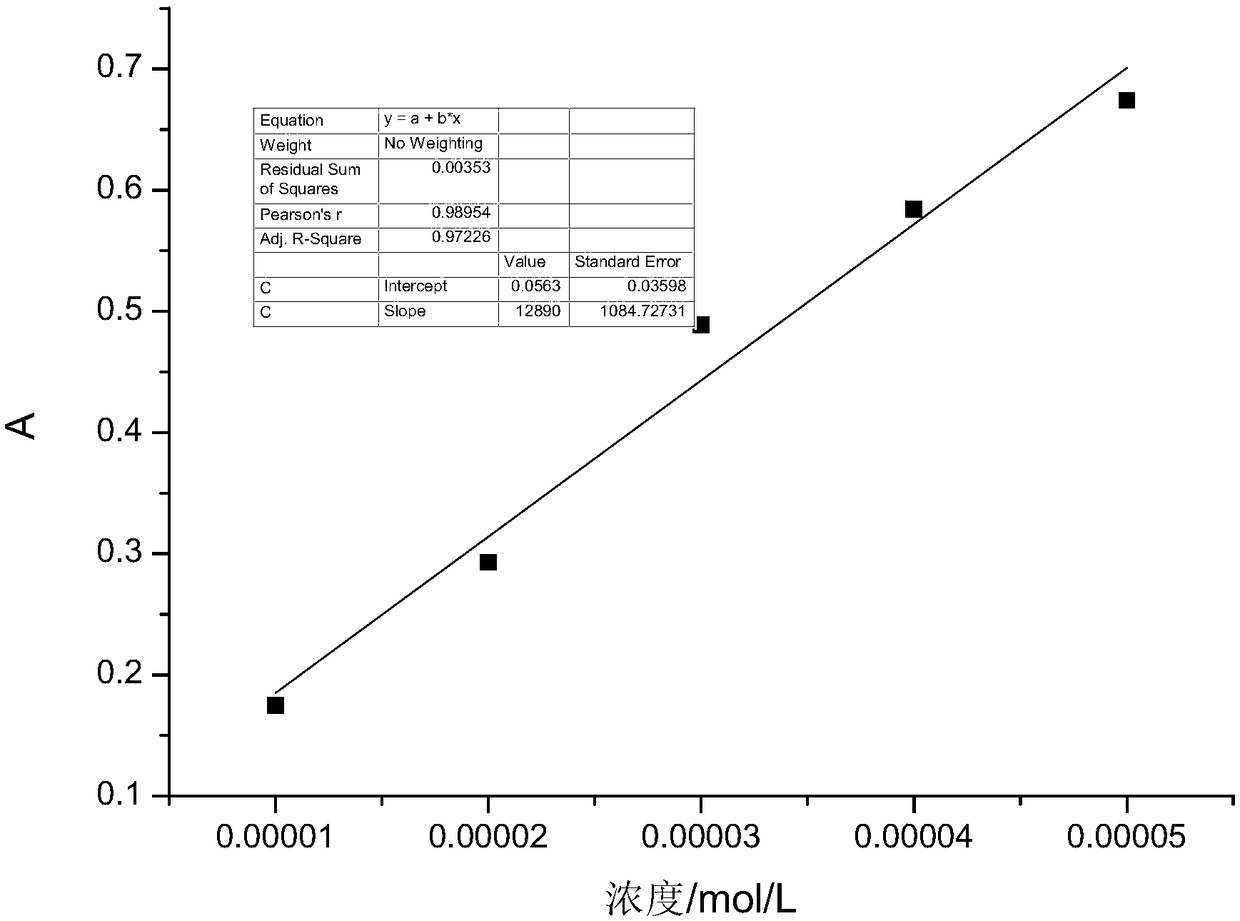

[0039] UV spectrum characterization:

[0040] The ultraviolet spectrum characterization was carried out on a UV-721 ultraviolet spectrophotometer, the experimental temperature was 25°C, and the solution was diluted to 10 -5~10 -6 Order of magnitude, the measurement wavelength range is 200-800nm, find out the maximum absorption peak, the absorption peak of nitrobenzene is around 260nm, and the absorption peak of aniline is around 286nm. At 4h, 5h, 24h, 48h, and 49h, the conversion rates of nitrobenzene were 5%, 7.66%, 20.01%, 40.53%, and 42.24% respectively; the yields of aniline were 0, 0, 6.8%, 8.7%, respectively. 11.82%.

Embodiment 6

[0042] A preparation method for a highly active hydrogenation reaction catalyst, comprising the steps of:

[0043] 1) Using azobisisobutyronitrile as the initiator, polyvinylpyrrolidone as the dispersant, and ethanol and water as the solvent, copolymerize styrene and acrolein to prepare a polystyrene aldehyde-based microsphere emulsion, which is centrifuged Separation, washing, and drying to obtain polystyrene aldehyde-based microspheres; wherein the mass of dispersant, initiator, styrene and acrolein are 2.4g, 0.08g, 5g (5.5ml), 2.2g (2.6ml) respectively; The specific method is: Dissolve polyvinylpyrrolidone in a mixed solution of ethanol and deionized water to form a polyvinylpyrrolidone solution, wherein the dosages of polyvinylpyrrolidone, ethanol and deionized water are 2.4g and 14g (17.5ml) respectively , 24g (24ml); The initiator azobisisobutyronitrile is dissolved in styrene to obtain the monomeric styrene that is dissolved with the initiator AIBN; then the polyvinylpy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com