A degradable drug-loaded occluder, forming and unfolding method of the occluder

An occluder and drug-loading technology, which is applied in the field of medical devices, can solve the problems of non-degradable nickel-titanium-cobalt alloy wire occluders and large fluctuations in blood drug concentration, so as to avoid metal poisoning and complications, reduce pain, and avoid The effect of the attenuation of plasma drug concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

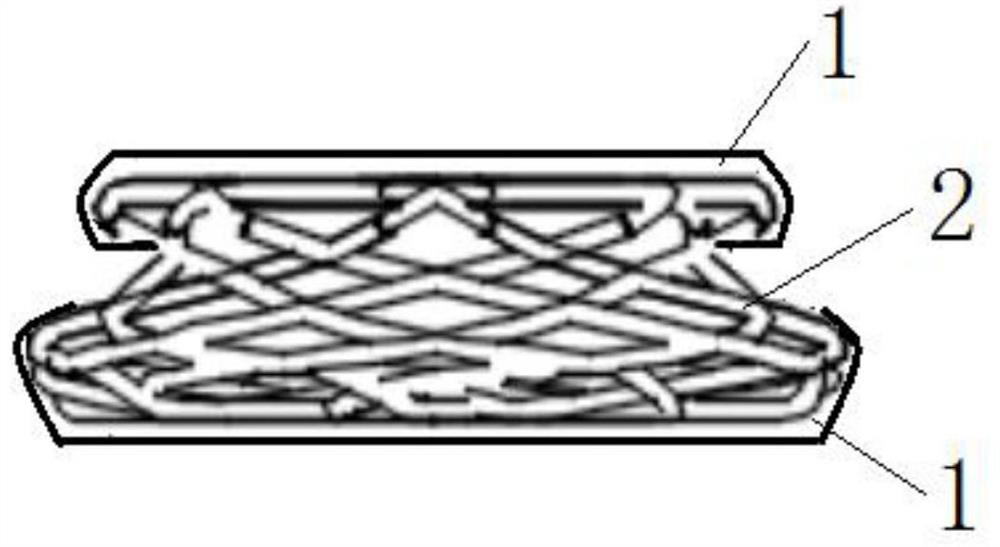

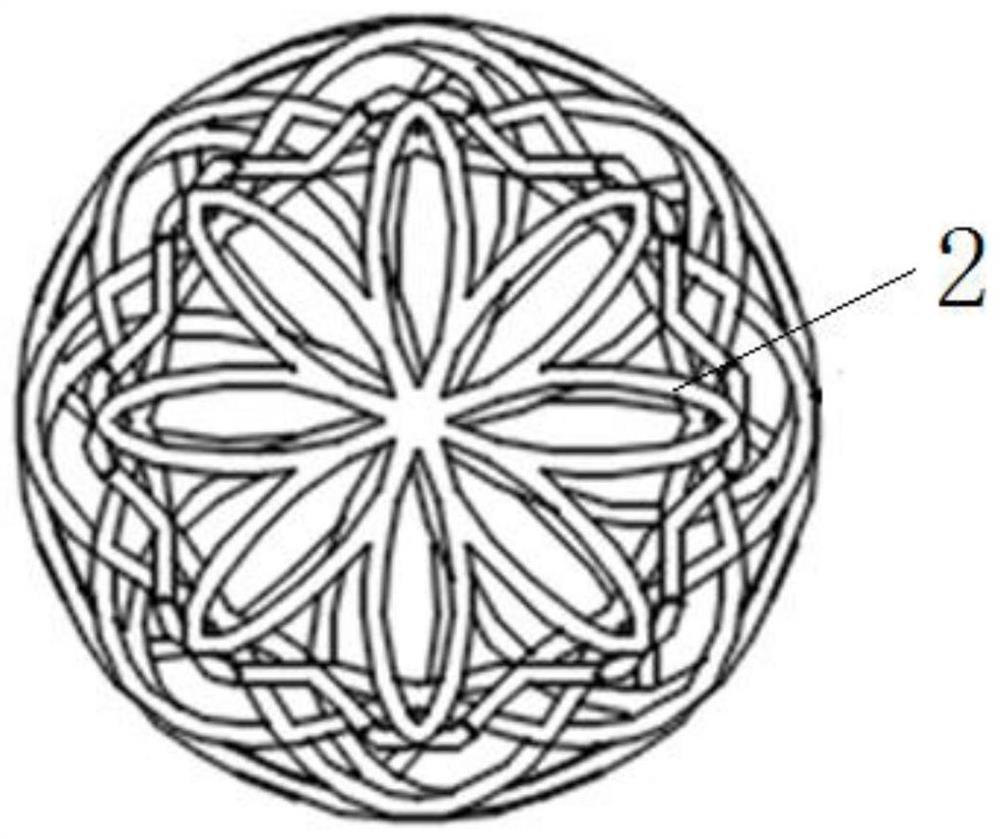

[0066] Such as Figure 2-Figure 4 and Figure 6 Shown is a schematic diagram of the unfolded state of the degradable drug-loaded occluder based on fused deposition 4D printing. The support structure of the occluder is a degradable shape memory polymer, which is petal-shaped and double-disc thin-waisted structure, and its surface has a micro-nano structure that can be loaded with drugs 2-1, such as Figure 6 shown. Before implantation, the support structure 2 is immersed in the medical solution that is beneficial to the patient's recovery in the early stage after the operation, and the micro-nano structure 2 automatically loads the drug, and the concentration of the drug is controlled according to the concentration of the drug solution.

Embodiment 2

[0068] The support structure 2 is a degradable shape-memory polymer, including a mixture of one or more of shape-memory polylactic acid, shape-memory polycaprolactone, shape-memory chitosan, and shape-memory polyurethane; its glass transition temperature is 38 In the range of -50°C, the driving method is one or more of thermal driving, solution driving and magnetic driving. The polymer is mixed with ferric oxide and developer, and the developer includes barium sulfate, metal tantalum, molybdenum target, diatrizoate meglumine, iohexol or iotaramic acid, and the developer is in It plays a positioning function during the delivery and deployment of the occluder. At the same time, the polymer also contains drugs that are beneficial to the patient during the rehabilitation stage, including cefuroxime, ankexin, clindamycin, amoxicillin, piperacillin, One or more mixtures of penicillin sodium.

[0069] It can be configured according to the following components in terms of mass percen...

Embodiment 3

[0071] A 4D printing-based developable and degradable drug-loaded occluder unfolds and collapses as follows:

[0072] The drive mode is magnetic drive

[0073] 1. Heating the occluder in the expanded state to above the glass transition temperature of the shape-memory polymer of the support structure; the occluder includes the following components: a mixture of ferroferric oxide and shape-memory polymer and a flow-blocking membrane ;

[0074] 2. Apply an axial pulling force to the occluder until the occluder is in a closed state, maintain the load and quickly cool down to below the glass transition temperature of the shape memory polymer used, and fix the closed state;

[0075] 3. Put the occluder in the collapsed state into the delivery sheath, and send the head of the sheath to the defect;

[0076] 4. The sheath is connected to the air pump, and when it reaches the defect site, the air pump will push the occluder out of the sheath;

[0077] 5. A local magnetic field is app...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com