Apparatus and method for electrochemically assisting aerobic composting of organic solid waste

An organic solid and aerobic composting technology, which is applied in the fields of solid waste removal, organic fertilizer preparation, chemical instruments and methods, etc., can solve the problems of complex and cumbersome system configuration, cumbersome start-up process, and incomplete killing, etc., to achieve The effect of overcoming a large number of ineffective aeration, improving the killing efficiency, and increasing the degree of humification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

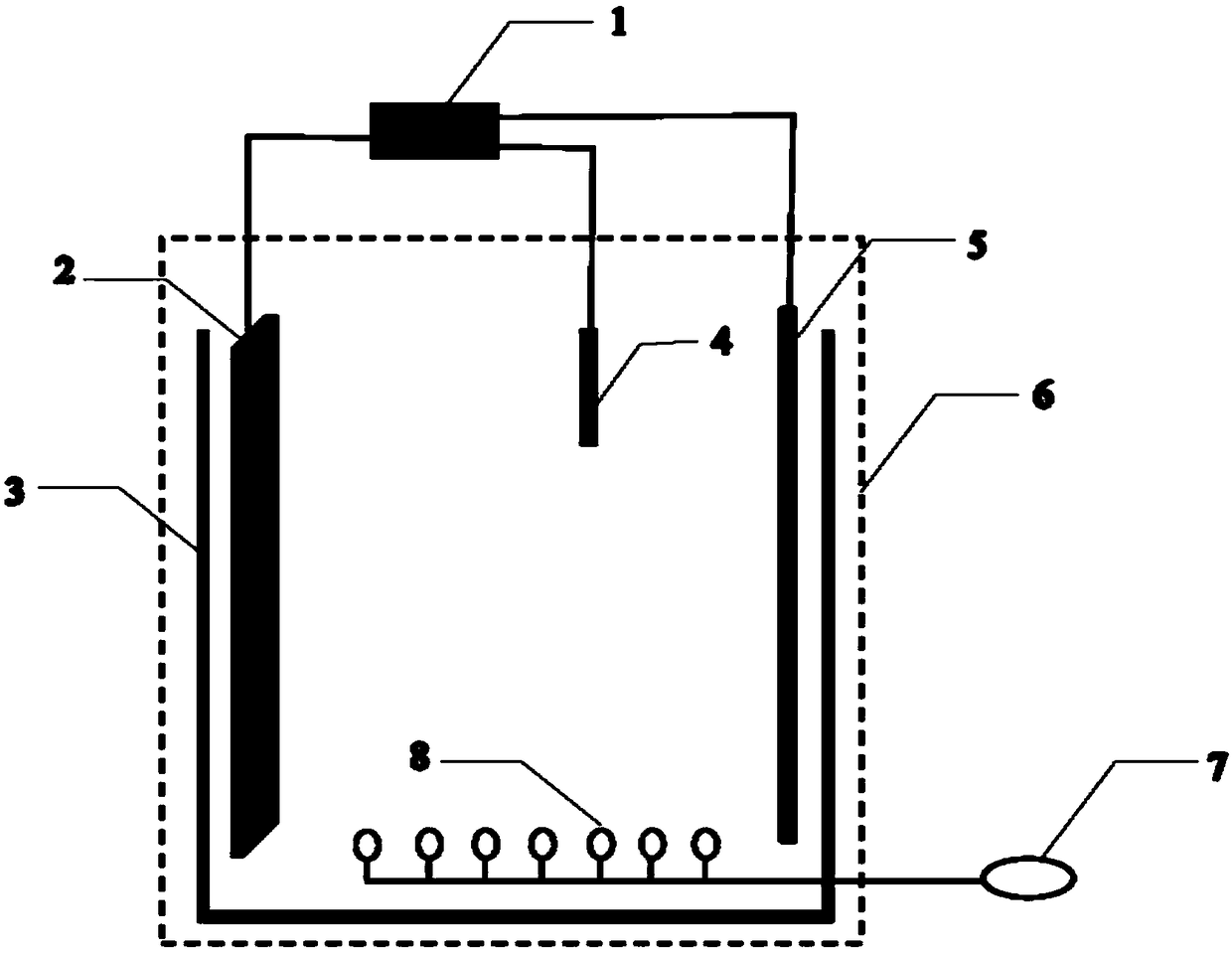

[0047] 1) Design of composting reactor:

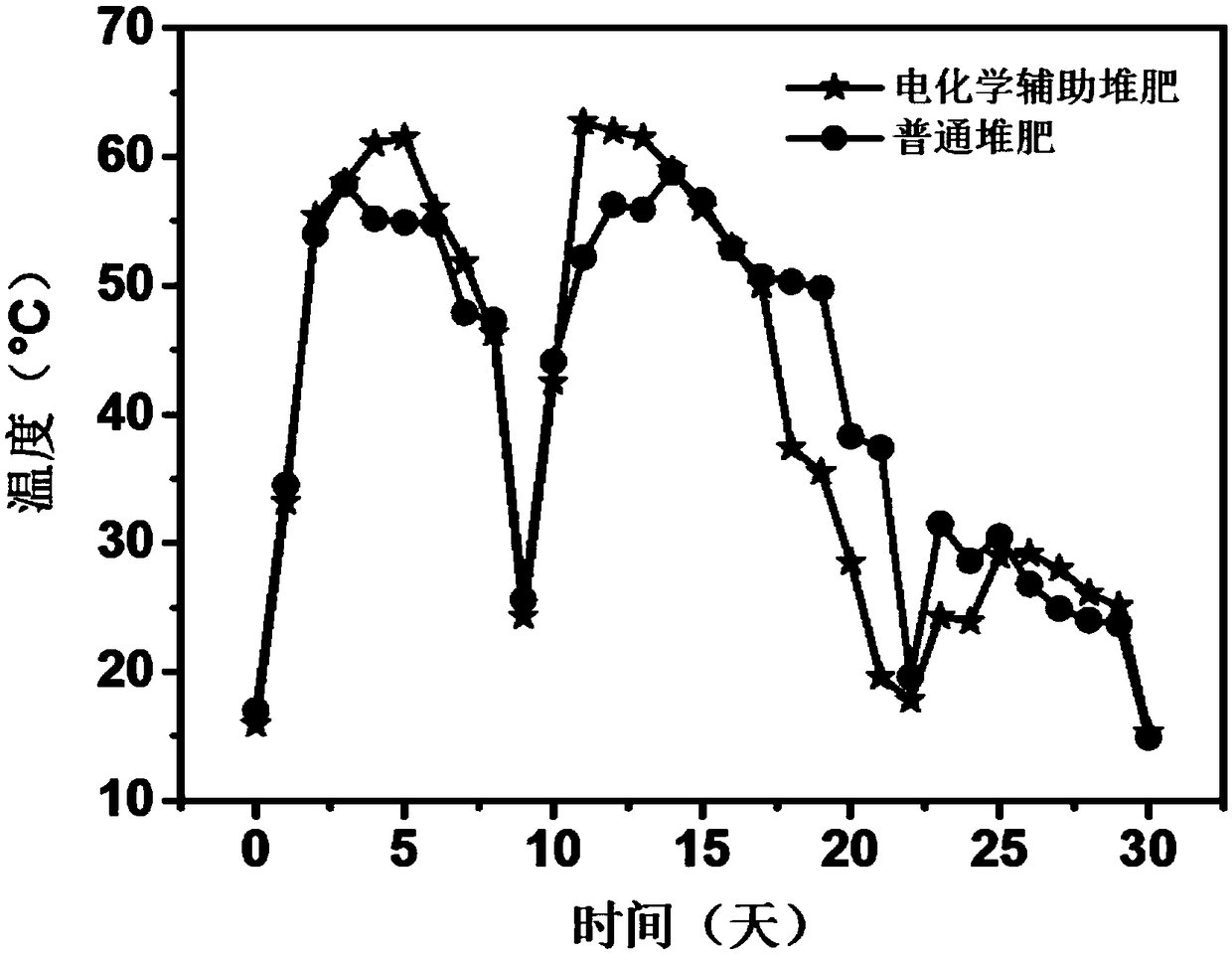

[0048] A cylindrical composting reactor is used: 55cm in diameter and 100cm in height. Arrange a rectangular working electrode along the inner wall of the plastic barrel, the material is stainless steel plate, the area is 3-5m 2 . In the center of the plastic barrel, place a cylindrical auxiliary electrode: a circular tube as the inner center, with a diameter of 5 cm and a height of 80 cm; on the upper part of the plastic barrel, connect a saturated calomel reference electrode. Plastic bucket bottom setting In order to make the aeration uniform, the height of the ventilation pipe is 30-50cm, and an aeration hole is made every 10cm from the bottom to 30cm, and an aeration hole is made every 20cm at 30-50cm. The outer wall of the plastic barrel is wrapped with cotton fiber, which is used for the insulation of the reactor. At the same time, an online thermometer is set around the plastic barrel to record the temperature change of the...

Embodiment 2

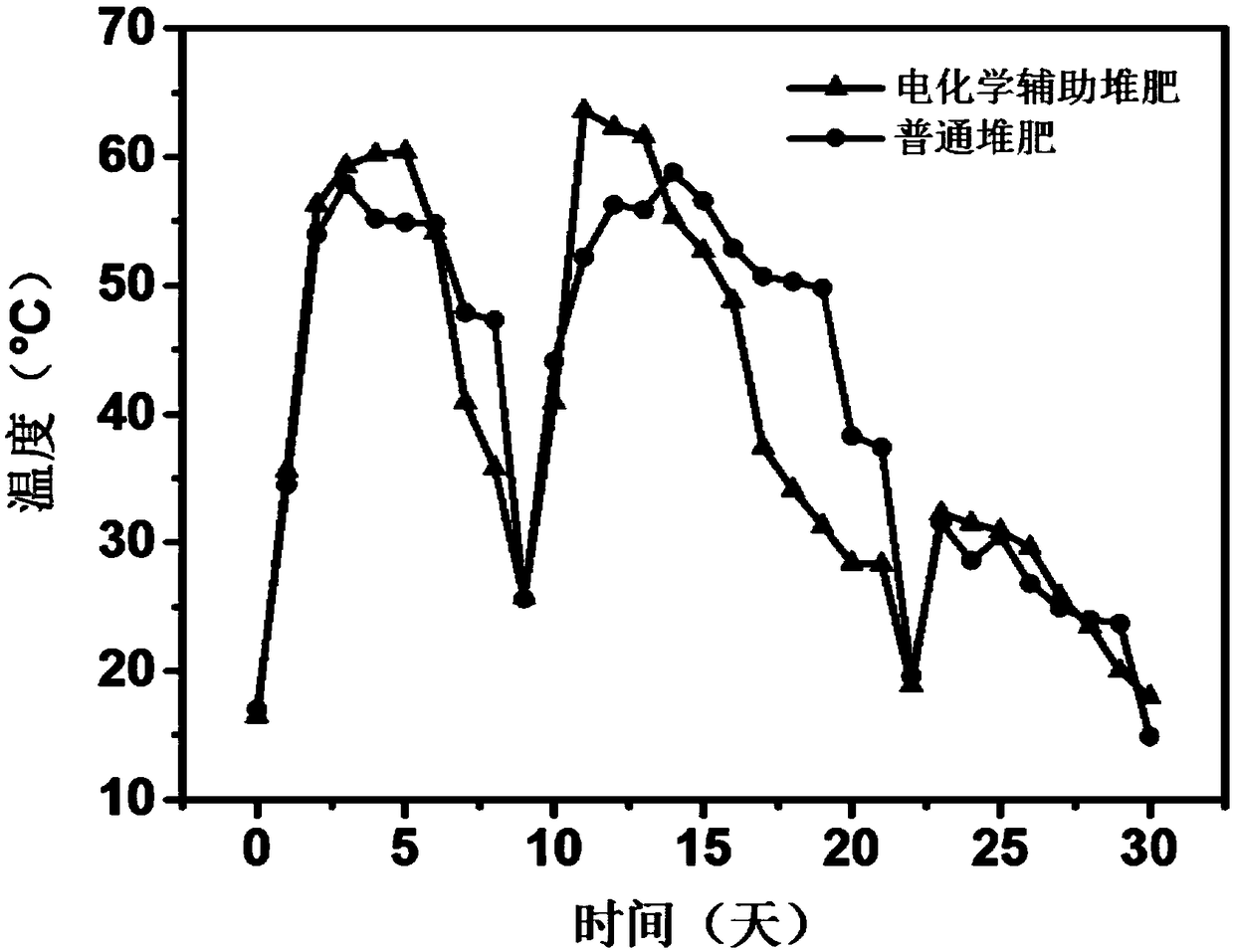

[0054] A bar-shaped composting reactor is used, which is 2 meters long, 1 meter wide and 1 meter high. Arrange a rectangular working electrode along the long side, the material is graphite plate, the area is about 1m 2 . On the other side of the long side, place an auxiliary electrode of the same size: a saturated calomel reference electrode is connected to the upper part of the stack. bottom setting In order to make the aeration uniform, the height of the ventilation pipe is 30-50cm, and an aeration hole is made every 10cm from the bottom to 30cm, and an aeration hole is made every 20cm at 30-50cm, and the aeration hole is Gas working parameters are the same as in Example 1. The outer wall of the reactor is wrapped with cotton fibers for the insulation of the reactor. At the same time, online thermometers are installed around the inside of the heap to record the temperature changes of the compost in real time. The potential setting of the potentiostat is: +5V vs SCE (sa...

Embodiment 3

[0057] Embodiment 3 and embodiment 2 adopt the same composting reactor, with pig manure as compost raw material, rice husk as auxiliary material, mass ratio is 10:1, potentiostat potential setting is: -5V vs SCE (saturated calomel electrode is reference electrode). All the other are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com