Processing method for promoting softness of sugar cane vinegar

A processing method and technology of sugarcane vinegar, which is applied in the field of food processing, can solve problems such as poor taste and impure flavor of sugarcane vinegar, and achieve the effect of improving taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

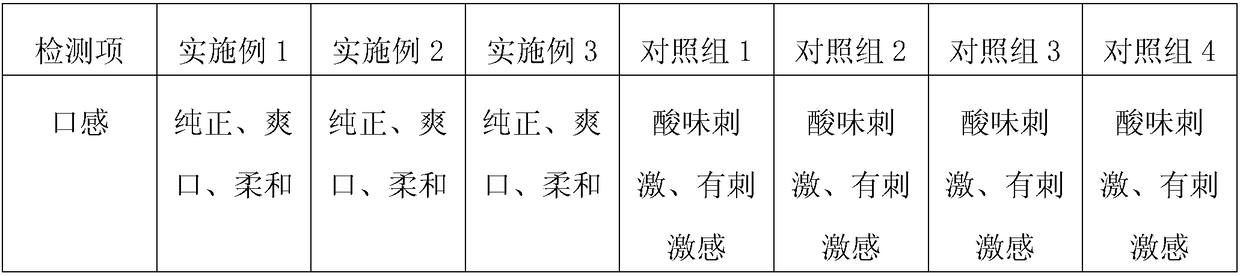

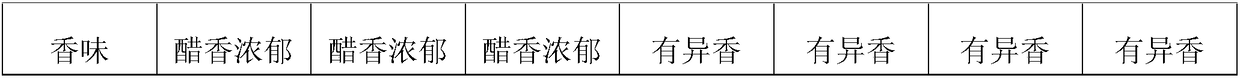

Examples

Embodiment 1

[0025] A processing method for improving the softness of sugarcane vinegar, comprising the steps:

[0026] (1) Sugarcane pretreatment: cleaning and pressing the sugarcane into juice;

[0027] (2) Filtration: adopt plate and frame filter press to filter sugarcane juice;

[0028] (3) The ingredients are pasteurized to obtain the sugarcane vinegar.

[0029] Wherein, the mass ratio of konjac mannan, mogroside and pumpkin juice is 1:15:5.

[0030] Wherein, adjusted; adjust the soluble solids content of sugarcane juice to be 18% with white granulated sugar, juniper polysaccharide, camellia oleifera polysaccharide, β-carotin, ursolic acid and deionized water, and then use potassium dihydrogen phosphate to adjust pH value to 5; the mass ratio of the white granulated sugar, juniper polysaccharide, camellia oleifera polysaccharide, β-carotin, and ursolic acid is 20:3:1:1:0.1;

[0031] (4) Sterilization: pasteurize the fermented liquid;

[0032] (5) Alcoholic fermentation: add Saccha...

Embodiment 2

[0037] A processing method for improving the softness of sugarcane vinegar, comprising the steps:

[0038] (1) Sugarcane pretreatment: cleaning and pressing the sugarcane into juice;

[0039] (2) Filtration: adopt plate and frame filter press to filter sugarcane juice;

[0040] (3) The ingredients are pasteurized to obtain the sugarcane vinegar.

[0041] Wherein, the mass ratio of konjac mannan, mogroside and pumpkin juice is 1:10:8.

[0042] Wherein, adjusted; adjust the soluble solids content of sugarcane juice to be 18% with white granulated sugar, juniper polysaccharide, camellia oleifera polysaccharide, β-carotin, ursolic acid and deionized water, and then use potassium dihydrogen phosphate to adjust pH value to 4.5; the mass ratio of the white granulated sugar, fern polysaccharide, camellia oleifera polysaccharide, β-carotin, and ursolic acid is 40:1:3:0.1:1;

[0043] (4) Sterilization: pasteurize the fermented liquid;

[0044] (5) Alcoholic fermentation: add Sacchar...

Embodiment 3

[0049] A processing method for improving the softness of sugarcane vinegar, comprising the steps:

[0050] (1) Sugarcane pretreatment: cleaning and pressing the sugarcane into juice;

[0051] (2) Filtration: adopt plate and frame filter press to filter sugarcane juice;

[0052] (3) The ingredients are pasteurized to obtain the sugarcane vinegar.

[0053] Wherein, the mass ratio of konjac mannan, mogroside and pumpkin juice is 1:12:6.

[0054] Wherein, adjusted; adjust the soluble solids content of sugarcane juice to be 18% with white granulated sugar, juniper polysaccharide, camellia oleifera polysaccharide, β-carotin, ursolic acid and deionized water, and then use potassium dihydrogen phosphate to adjust pH value up to 4.8; the mass ratio of the white granulated sugar, zina polysaccharide, camellia oleifera polysaccharide, β-carotin, and ursolic acid is 30:2:2:0.3:0.5;

[0055] (4) Sterilization: pasteurize the fermented liquid;

[0056] (5) Alcoholic fermentation: add Sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com