Needle-sized nanometer iron oxide adsorbent and preparation method thereof

An iron oxyhydroxide and adsorbent technology, applied in chemical instruments and methods, adsorbed water/sewage treatment, other chemical processes, etc., can solve the problem of high preparation cost of iron oxyhydroxide, and achieve environmental protection and emission reduction. The process is easy and widely used Prospects, the effect of cheap and easily available raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1 Preparation of needle-like nano-iron oxyhydroxide adsorbent

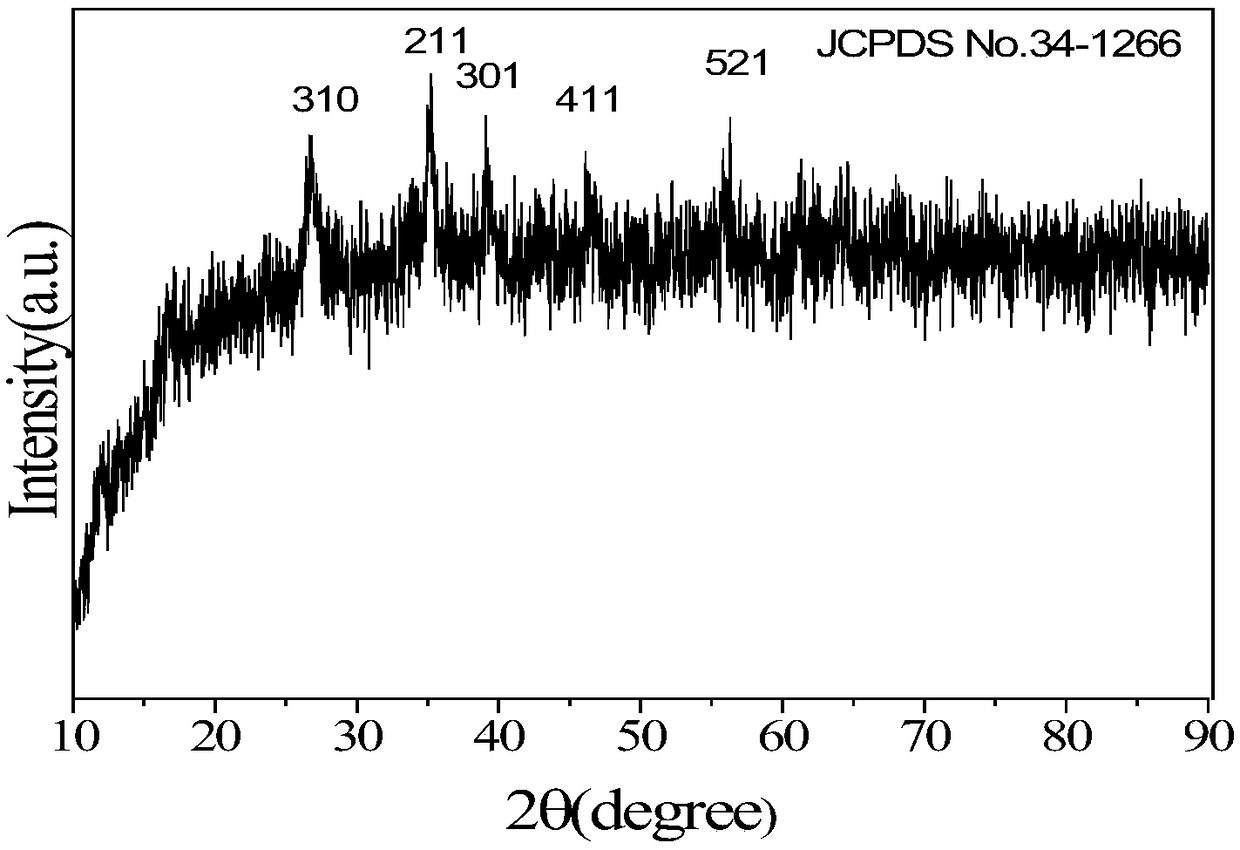

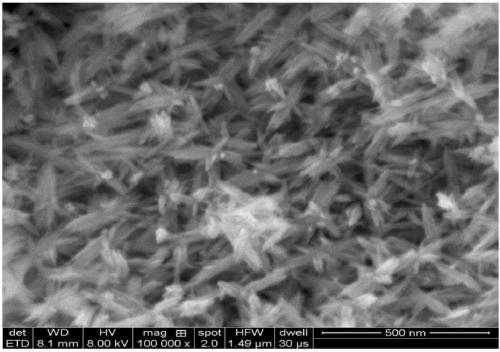

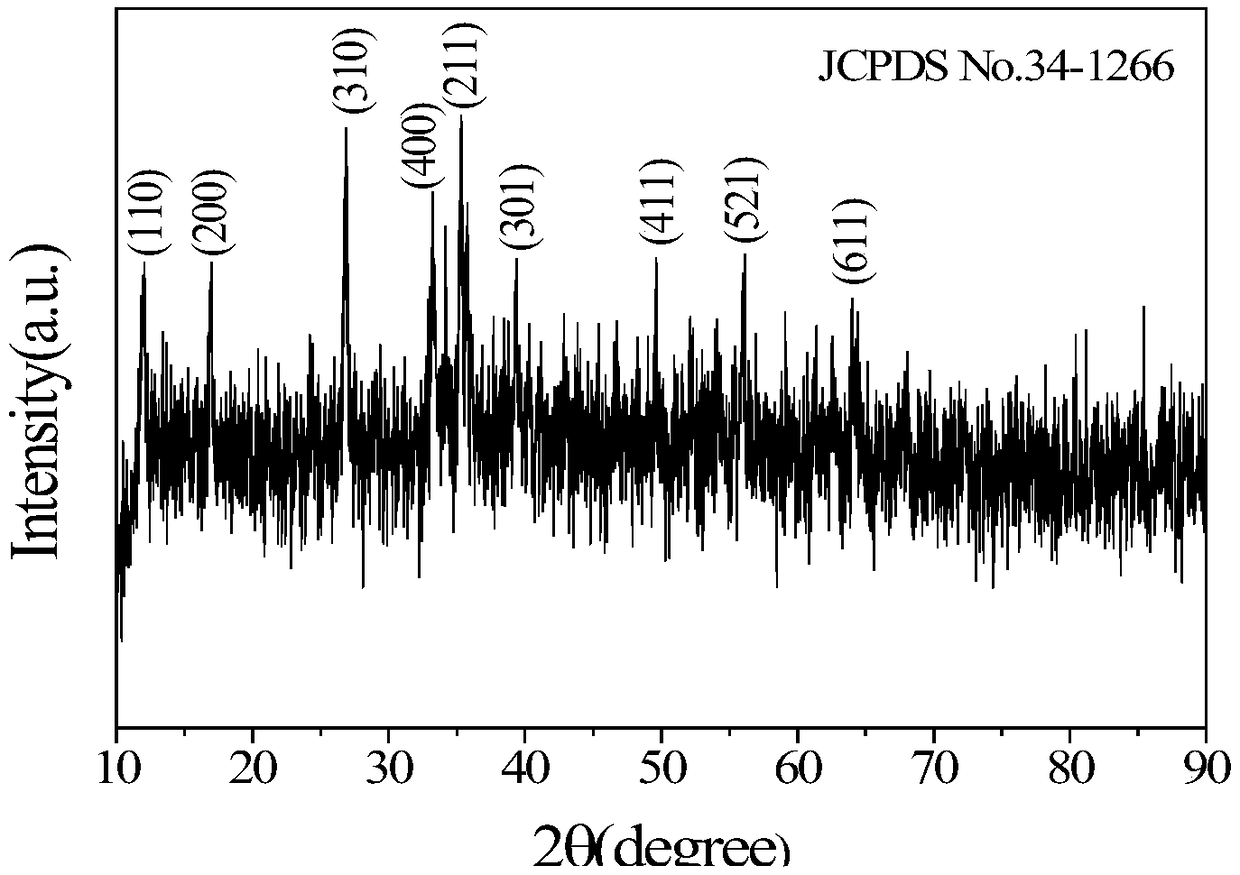

[0031] Weigh 2.16 g FeCl respectively 3 ·6H 2 O and 0.36 g urea were added to a mixture of 30 mL glycerol and 30 mL deionized water, stirred and ultrasonicated for a total of 10 min, and an orange-yellow transparent reaction solution was obtained after dissolution. The above reaction solution was transferred to a polytetrafluoroethylene-lined autoclave for solvothermal reaction at 140 °C for 3 h, cooled to room temperature after the reaction, and washed with deionized water and ethanol three times in sequence. Dry it in an oven at 80 °C for 4 h, and grind it into a powder, that is, sample S1; its X-ray diffraction pattern and scanning electron microscope pattern are as follows: figure 1 and figure 2 shown. Depend on figure 1 It can be seen that the peaks at (310), (211), (301), (411) and (521) of the synthesized adsorbent are the characteristic diffraction peaks of iron oxyhydroxide, which is ...

Embodiment 3

[0034] Example 3 The adsorption performance of iron oxyhydroxide adsorbent to Congo red

[0035] Select Congo red as the target toxic and harmful dye pollutant, and simulate the dye-contaminated water body: Weigh 0.4 g of Congo red solid powder, dissolve it with a small amount of deionized water ultrasonically, transfer it to a 1000 mL volumetric flask to constant volume, and then configure 400 mg / L Congo red solution, as a simulated Congo red polluted water sample.

[0036]Use a pipette to take 2 parts of 20 mL Congo red solution and place them in 2 Erlenmeyer flasks respectively. At room temperature, add 0.02 g of adsorbents S1 and C1 respectively, put them into a constant temperature oscillator at 25 °C and oscillate at 200 r / min for adsorption. At 5, 10, 20, 40, 60, 80, and 100 min of adsorption, the concentration of Congo red in C1 was measured with a UV-visible spectrophotometer. At 90 and 100 min, the concentration of Congo red in S1 was measured by UV-Vis spectrophot...

Embodiment 4

[0038] Example 4 N of the needle-shaped nano-iron oxyhydroxide adsorbent 2 Adsorption-desorption curve and pore size distribution characterization

[0039] Use N 2 Determination of specific surface and pore structure by static adsorption capacity method: use a fully automatic specific surface area and pore size analyzer ASAP2000 (Micromeritics, USA). Before the test, the adsorbent samples were first degassed in vacuum for 5 hours, and then cooled to a temperature close to the liquidation point of nitrogen (77K) for nitrogen adsorption and desorption tests. The specific surface area of the adsorbent was calculated by the adsorption isotherm model equation proposed by BET. Due to the phenomenon of capillary condensation, a hysteresis loop will be formed on the adsorption-desorption curve, so as to obtain the pore structure information, and calculate the average pore size and pore size distribution by BJH method, the results are as follows Figure 7 shown. Figure 7 Typical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com