A kind of synthesis technique of creatine ethyl ester hydrochloride

A technology of creatine ethyl ester hydrochloride and creatine, applied in the field of organic synthesis, can solve the problems of high purification process requirements, low synthesis yield and purity, high production cost of creatine ethyl ester hydrochloride, and achieve control Emission, the effect of increasing the reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

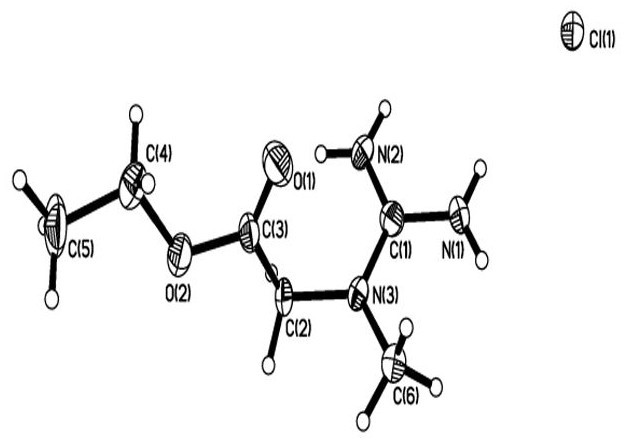

[0043] Add 1000g of absolute ethanol, 1.0g of 4-dimethylaminopyridine, 100.0g of anhydrous creatine to a 2000mL flask with a stirring device in sequence, stir and cool down to 10°C, start adding 127g of thionyl chloride dropwise, and the dropping rate is controlled It is advisable that the reaction temperature does not exceed 30° C., and react for 30 minutes after the dropwise addition is completed. After filtration, it was dried in a hot air oven at 100°C to obtain 126.5 g of a white solid (based on anhydrous creatine, the yield was 85%). The white solid was dissolved in water, and then ethanol was slowly added to precipitate a large number of white prismatic crystals. It was confirmed by single crystal diffraction that it was ethyl creatine hydrochloride.

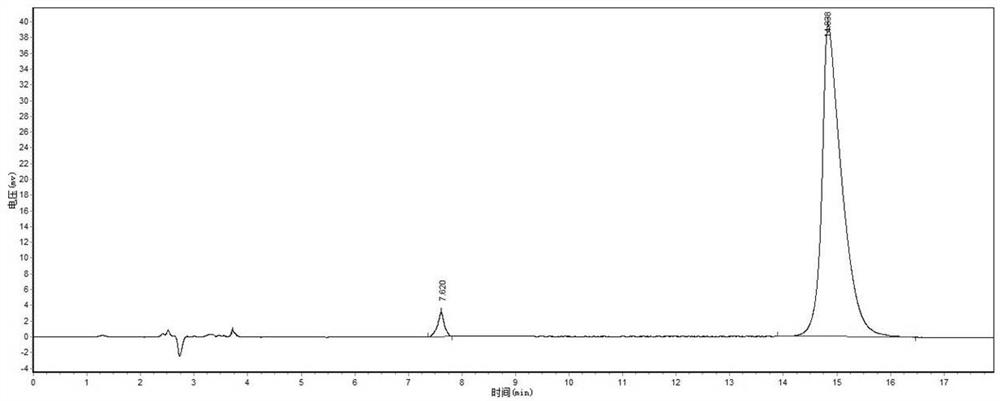

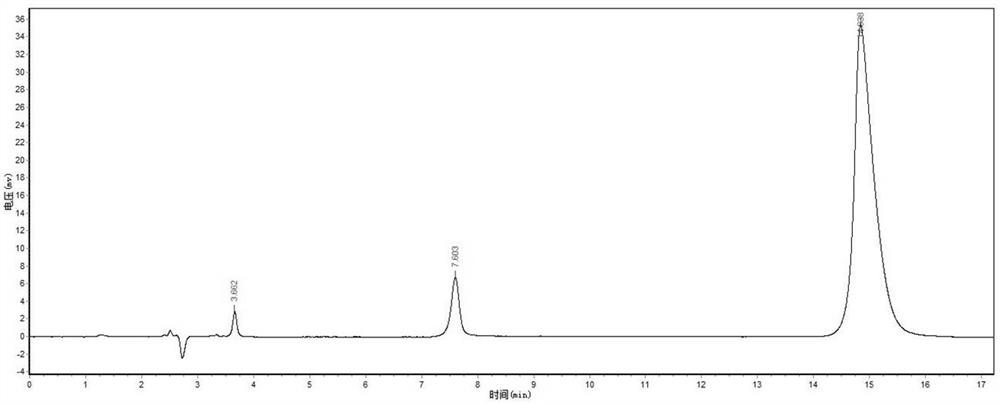

[0044] figure 1 It is the x-ray single crystal diffraction thermal ellipsoid figure of embodiment 1 creatine ethyl ester hydrochloride. figure 2 Infrared spectrum of creatine ethyl ester hydrochloride. pass figure 1...

Embodiment 2

[0047] Add 1000g of absolute ethanol, 1.0g of 4-dimethylaminopyridine and 100.0g of creatine monohydrate in sequence in a 2000mL flask with a stirring device, stir and cool down to 10°C, start adding 140g of thionyl chloride dropwise, and the dropping rate is controlled It is advisable that the reaction temperature does not exceed 30° C., and react for 30 minutes after the dropwise addition is completed. After filtration, it was dried in a hot air oven at 100°C to obtain 105 g of a white solid (based on anhydrous creatine, the yield was 80%).

Embodiment 3

[0049] Add 1000g of ethanol, 1.0g of 4-dimethylaminopyridine, and 100g of creatine monohydrate in sequence in a 2000mL flask with a stirring device, stir and cool down to 10°C, and start to add 100g of carbonyl chloride dropwise (using concentrated sulfuric acid and carbon tetrachloride Prepared by reaction, slowly added after low-temperature condensation), and reacted for 30 minutes after the dropwise addition was completed. After filtration, it was dried in a hot air oven at 100°C to obtain 117 g of a white solid (based on anhydrous creatine, the yield was 89%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com