An Au@ZnO core-shell heterojunction type triethylamine gas-sensitive sensor modified with boron-doped graphene and a preparing method thereof

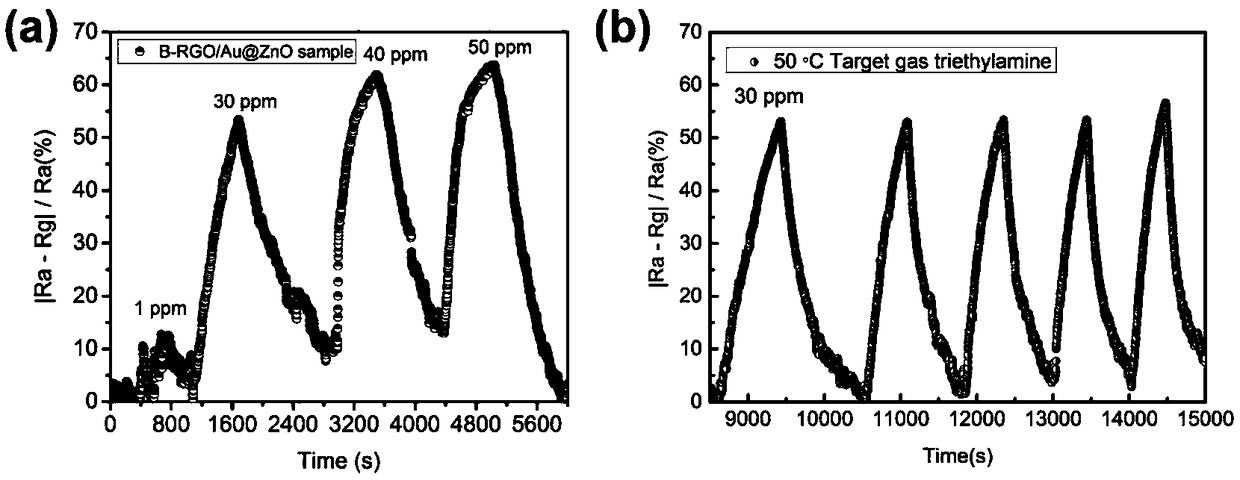

A technology of graphene and boron doping, applied in the direction of instruments, scientific instruments, nanotechnology for materials and surface science, etc., can solve the problems of lack of stability test, lower operating temperature, and inability to judge performance, etc., to achieve large applications value, reduce operating temperature, and improve the effect of device sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

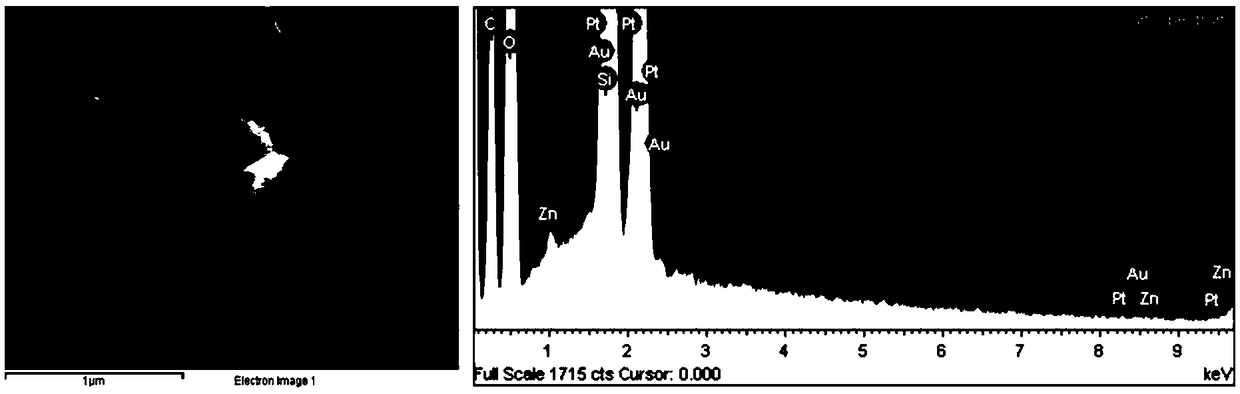

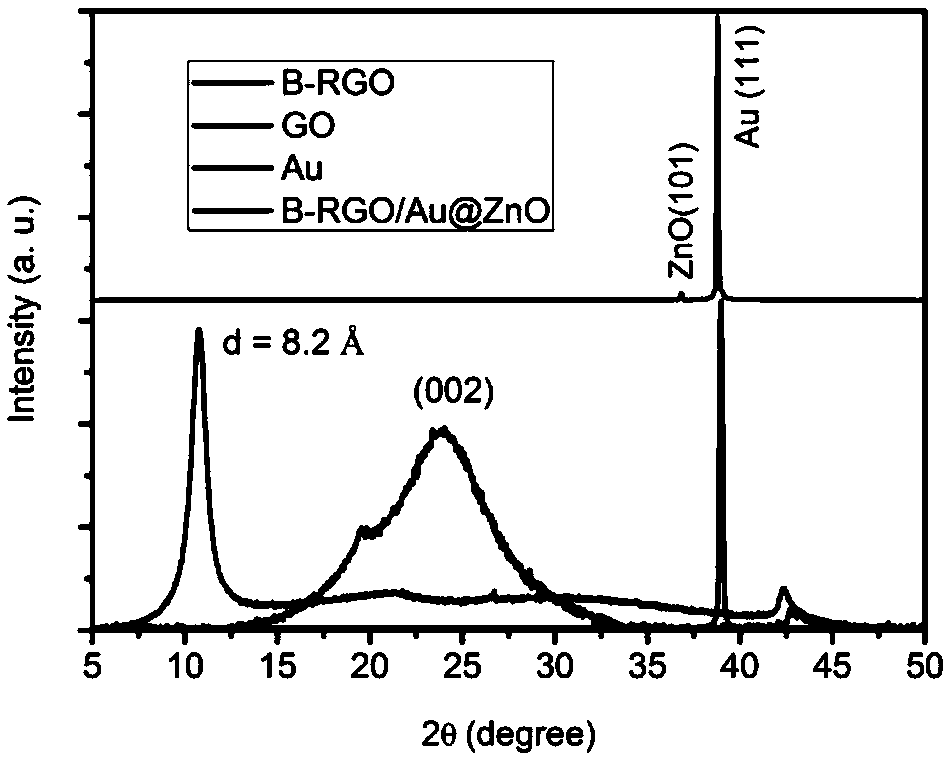

[0055] A method for preparing a boron-doped graphene-modified Au@ZnO core-shell heterojunction triethylamine gas-sensing material, comprising the following steps:

[0056] (1) Preparation of nuclear structure: using DC magnetron sputtering technology on SiO 2 (300nm) / Si substrate was sputter-deposited a 300nm-thick gold nanoparticle film with the same area as the substrate, sputtering power 30W, pressure 0.5Pa, argon flow 20SCCM, and then annealed at 900°C in an argon atmosphere 10min, the annealing heating rate is 10°C / min, to obtain uniform and isolated gold particles covering the surface of the substrate, the diameter of the Au particles is controlled at the level of 300nm, and the gold particles are in the (111) preferred orientation;

[0057] (2) Preparation of shell structure: continue to use DC magnetron sputtering technology to deposit a zinc film on the surface of the gold particles in step (1), so that the zinc film is coated on the surface of the gold particles, spu...

Embodiment 2

[0062] A method for preparing a boron-doped graphene-modified Au@ZnO core-shell heterojunction triethylamine gas-sensing material, comprising the following steps:

[0063] (1) Preparation of nuclear structure: using DC magnetron sputtering technology on SiO 2 (300nm) / Si substrate was sputter-deposited a 300nm-thick gold nanoparticle film with the same area as the substrate, with a sputtering power of 30W, a pressure of 0.5Pa, and an argon flow rate of 20SCCM; then annealed at 950°C in an argon atmosphere 10min, the annealing heating rate is 10°C / min, and the gold particles uniformly and isolatedly covering the surface of the substrate are obtained, the diameter of the Au particles is controlled at the level of 100nm, and the gold particles are in the preferred orientation of (111);

[0064] (2) Preparation of shell structure: continue to use DC magnetron sputtering technology to deposit a zinc film on the surface of the gold particles in step (1), so that the zinc film is coat...

Embodiment 3

[0069] A method for preparing a boron-doped graphene-modified Au@ZnO core-shell heterojunction triethylamine gas-sensing material, comprising the following steps:

[0070] (1) Preparation of nuclear structure: using DC magnetron sputtering technology on SiO 2 (300nm) / Si substrate was sputter-deposited a 300nm-thick gold nanoparticle film with the same area as the substrate, with a sputtering power of 30W, a pressure of 0.5Pa, and an argon flow rate of 20SCCM; then annealed at 1000°C in an argon atmosphere 10min, the annealing heating rate is 10°C / min, and the gold particles uniformly and isolatedly covering the surface of the substrate are obtained, the diameter of the Au particles is controlled at the level of 100nm, and the gold particles are in the preferred orientation of (111);

[0071] (2) Preparation of shell structure: continue to use DC magnetron sputtering technology to deposit a zinc film on the surface of the gold particles in step (1), so that the zinc film is coa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com