Preparation and application for amine-terminated hyperbranched polymer grafted graphene oxide magnetic anion adsorbent

A technology of amino-terminated hyperbranching and polymers, which is applied in the fields of alkali metal compounds, adsorbed water/sewage treatment, alkali metal oxides/hydroxides, etc., and can solve the problem of low density of functional groups of adsorbents and solid-liquid separation of adsorbents Difficult and unsatisfactory effects, etc., to achieve the effect of not easy to decompose, stable structure and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] 1. a preparation method of an amino-terminated hyperbranched polymer grafted graphene oxide magnetic anion adsorbent, comprising steps as follows:

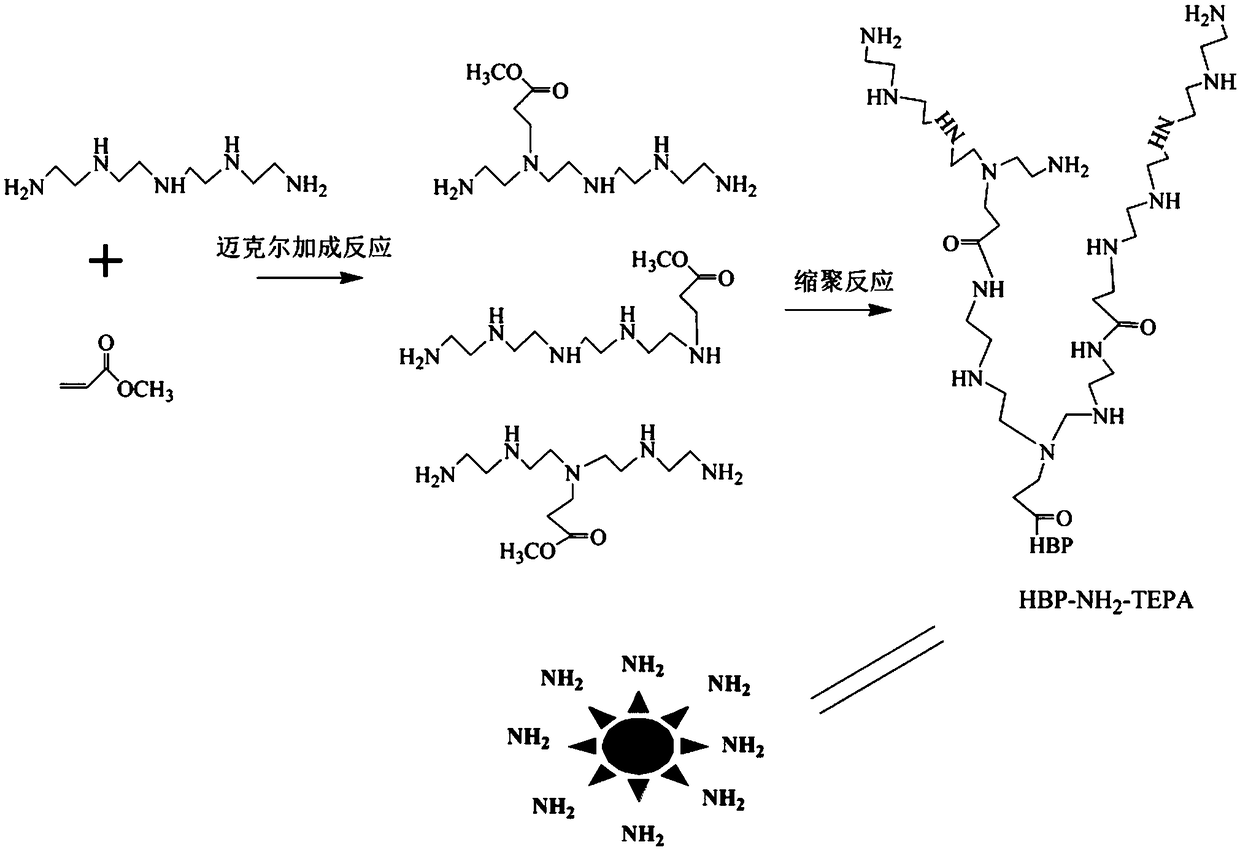

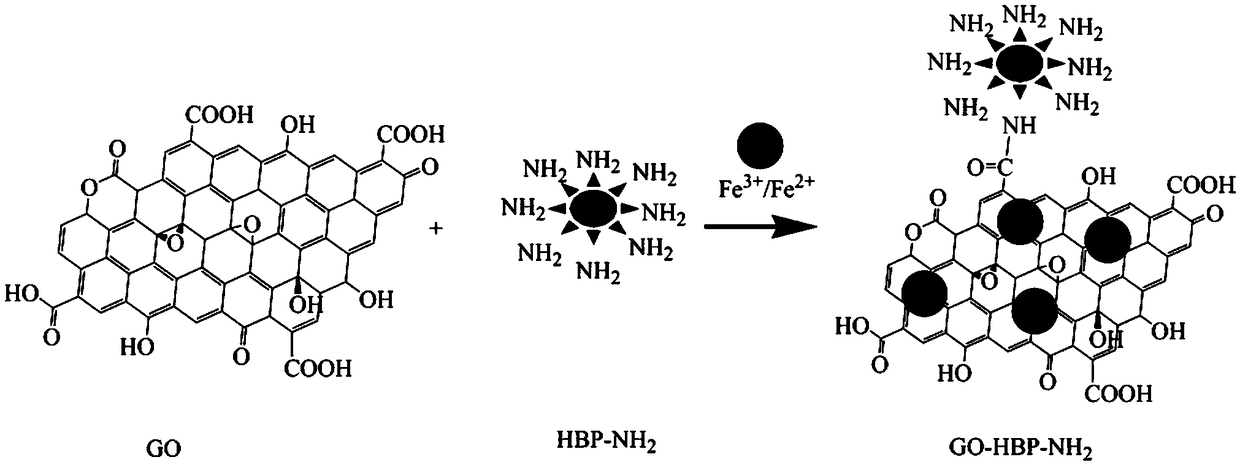

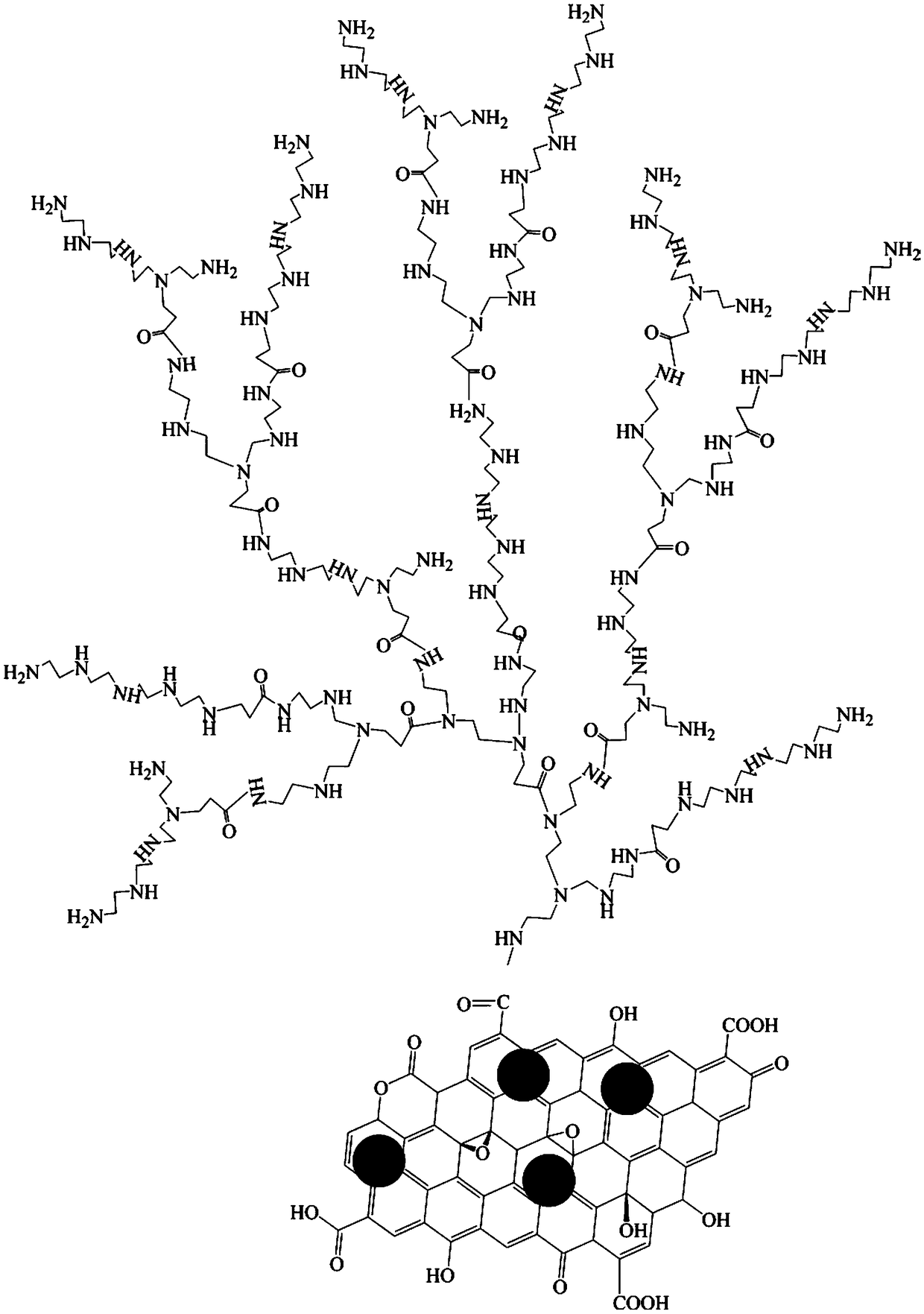

[0043] (1) Mix 0.5mol of diethylenetriamine with 50mL of anhydrous methanol, place at 0°C, and pass through N 2, after stirring for 10 min, the mixed solution of 1mol methyl acrylate (MA) and 50 mL of anhydrous methanol was slowly added dropwise to the mixed solution of diethylenetriamine and methanol, and Michael addition occurred between diethylenetriamine and methyl acrylate (MA). The resulting reaction yields a light yellow liquid which is the hyperbranched polymer precursor (intermediate product). Then transfer the obtained precursor to the round-bottomed flask of the rotary evaporator, and keep it at 60°C for 2h under the vacuum condition of the circulating water vacuum pump, and distill the solvent methanol under reduced pressure; then raise the temperature to 120°C and 140°C in sequence Keep stirring each vacuum co...

Embodiment 2

[0052] 1. a preparation method of an amino-terminated hyperbranched polymer grafted graphene oxide magnetic anion adsorbent, comprising steps as follows:

[0053] (1) Mix 0.5mol triethylenetetramine with 50mL of anhydrous methanol, place at 0°C, and pass through N 2 , after stirring for 10 min, the mixed solution of 1mol methyl acrylate (MA) and 50 mL of anhydrous methanol was slowly added dropwise to the mixed solution of triethylenetetramine and methanol, and Michael addition occurred between triethylenetetramine and methyl acrylate (MA). The resulting reaction yields a light yellow liquid which is the hyperbranched polymer precursor (intermediate product). Then transfer the obtained precursor to the round-bottomed flask of the rotary evaporator, and keep it at 60°C for 2h under the vacuum condition of the circulating water vacuum pump, and distill the solvent methanol under reduced pressure; then raise the temperature to 120°C and 140°C in sequence Keep stirring each vacuu...

Embodiment 3

[0062] 1. a preparation method of an amino-terminated hyperbranched polymer grafted graphene oxide magnetic anion adsorbent, comprising steps as follows:

[0063] (1) Mix 1mol of tetraethylenepentamine with 50mL of anhydrous methanol, place at 0°C, and pass through N 2 , after stirring for 10 min, the mixed solution of 0.5mol methyl acrylate (MA) and 50 mL of anhydrous methanol was slowly added dropwise to the mixed solution of tetraethylenepentamine and methanol, tetraethylenepentamine and methyl acrylate (MA) produced Michael Addition reaction, the light yellow liquid obtained is the hyperbranched polymer precursor (intermediate product). Then transfer the obtained precursor to the round-bottomed flask of the rotary evaporator, and keep it at 60°C for 2h under the vacuum condition of the circulating water vacuum pump, and distill the solvent methanol under reduced pressure; then raise the temperature to 120°C and 140°C in sequence Keep stirring each vacuum compression polym...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com