A kind of preparation method of titanium dioxide nanotube for solar cell

A technology of solar cells and titanium dioxide, applied in the direction of titanium dioxide, titanium oxide/hydroxide, circuits, etc., can solve the problems of low specific surface area, weak light dye adsorption capacity, poor photocatalytic effect, etc., and achieve large specific surface area , Improve the effect and efficiency of impurity removal, and improve the effect of permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

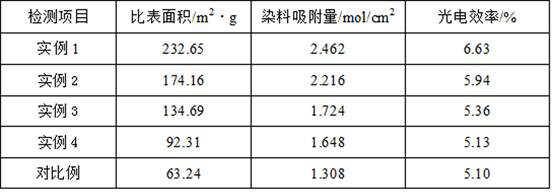

Examples

example 1

[0026]Stir and mix the rice husk and water at a mass ratio of 1:3, and then let it stand for 10 days at a temperature of 40°C to get stale rice husk; under high temperature conditions, high temperature sterilization for 30 minutes, and the sterilized stale rice husks were washed 5 times with deionized water to obtain washed stale rice husks, and then the washed stale rice husks were transferred to an oven and dried at a temperature of 110°C To constant weight, dry stale rice husks are obtained, then the dry stale rice husks and alkali are mixed in a mass ratio of 1:10 and poured into No. , after ultrasonic cleaning for 2 hours, filter to obtain No. 1 filter cake, and wash No. 1 filter cake with deionized water until the washing liquid is neutral, then mix the washed No. 1 filter cake and acid at a mass ratio of 1:8 and pour Put it into the No. 2 beaker, and move the No. 2 beaker into the ultrasonic oscillator. Under the condition of ultrasonic frequency of 60kHz, after ultraso...

example 2

[0028] In parts by weight, 30 parts of rice husk fibers with a diameter of 1 mm, 150 parts of tetrabutyl titanate dilution, and 20 parts of acetic acid solution are successively taken. The rice husk fibers with a diameter of 1 mm and tetrabutyl titanate dilution The mixture was poured into a four-necked flask, and at a temperature of 50°C and a stirring speed of 500r / min, the acetic acid solution was added dropwise to the four-necked flask through a dropping funnel at a rate of 5mL / min while stirring at a constant temperature. After the addition, continue to stir and react at constant temperature for 6 hours, then filter to obtain No. 3 filter cake, and wash No. 3 filter cake with deionized water for 6 times, then transfer the washed No. Dry to constant weight under the same conditions to obtain supported nanofibers; then transfer the obtained supported nanofibers into a tube furnace, and feed an inert gas into the tube furnace at a rate of 400mL / min. Under the protection of th...

example 3

[0030] Stir and mix the rice husk and water at a mass ratio of 1:3, and then let it stand for 10 days at a temperature of 40°C to get stale rice husk; under high temperature conditions, high temperature sterilization for 30 minutes, and the sterilized stale rice husks were washed 5 times with deionized water to obtain washed stale rice husks, and then the washed stale rice husks were transferred to an oven and dried at a temperature of 110°C To constant weight, dry stale rice husks are obtained, then the dry stale rice husks and alkali are mixed in a mass ratio of 1:10 and poured into No. , after ultrasonic cleaning for 2 hours, filter to obtain No. 1 filter cake, and wash No. 1 filter cake with deionized water until the washing liquid is neutral, then mix the washed No. 1 filter cake and acid at a mass ratio of 1:8 and pour Put it into the No. 2 beaker, and move the No. 2 beaker into the ultrasonic oscillator. Under the condition of ultrasonic frequency of 60kHz, after ultras...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com