Method for preparing high-purity ferric oxide red from industrial copper smelting slag

A technology for ferric oxide and copper smelting slag, which is applied in the direction of iron oxide/iron hydroxide, iron oxide, and process efficiency improvement, can solve the problems of low quality, high cost, dark iron red color, etc., and achieves particle size The effect of uniform distribution, bright color and regular appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

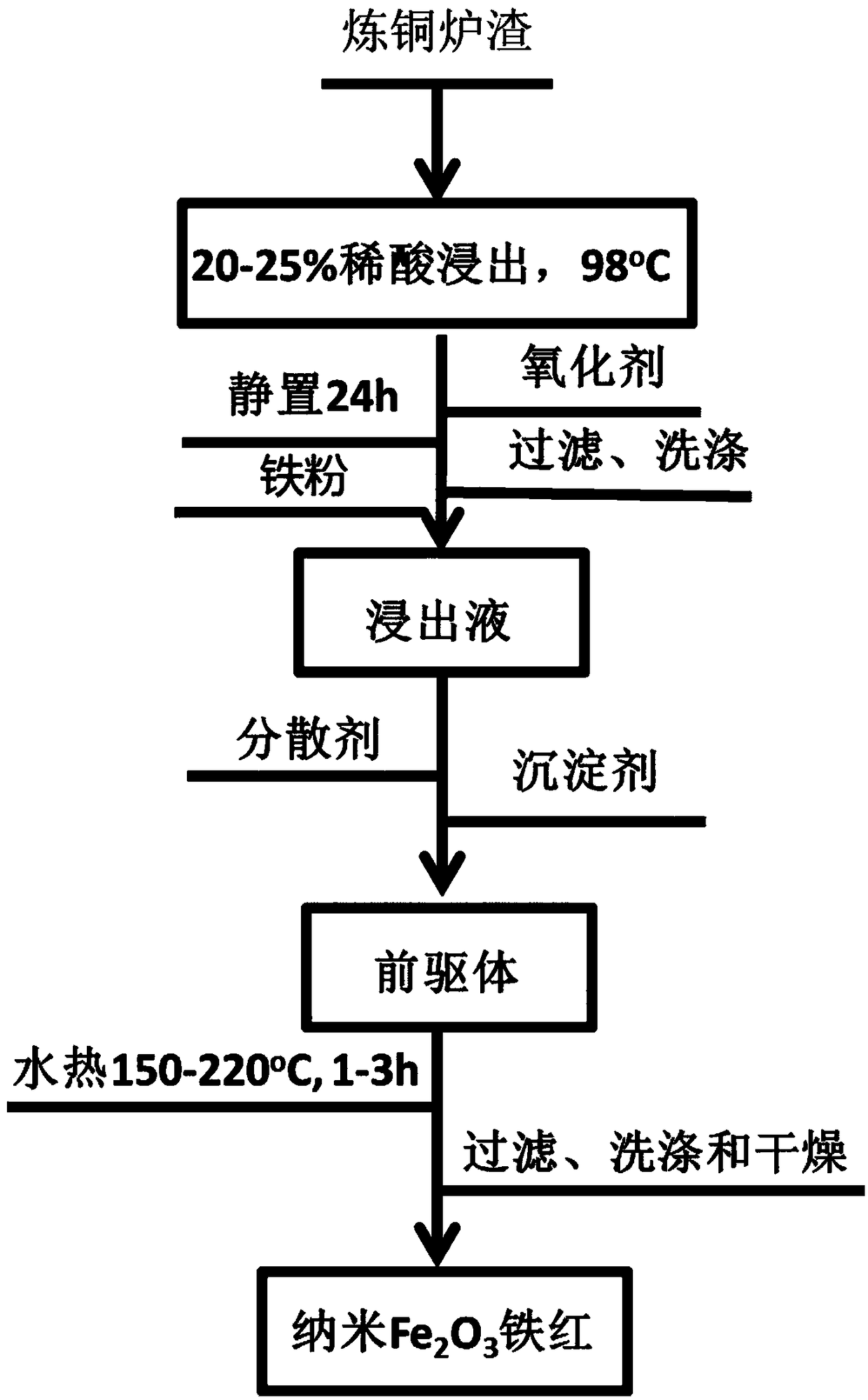

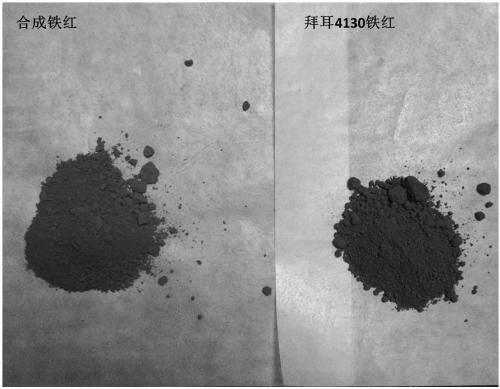

[0039] Such as figure 1 As shown, a kind of industrial copper smelting slag is used as raw material to prepare high-purity, high value-added Fe 2 o 3 Iron red method. figure 2 It is an optical photograph of industrial copper smelting slag. From figure 2 It can be seen that the copper smelting slag has a large size and irregular block structure, and the slag has a khaki appearance.

[0040] After crushing and grinding the industrial copper smelting slag, mix 100g of copper smelting slag with 500g of dilute hydrochloric acid with a concentration of 22%, transfer it into a three-necked round-bottomed flask, raise the temperature to 98°C in an oil bath, condense and reflux for 20 hours, and the reaction is over After cooling to room temperature, the mixture solution was filtered, 5g of oxidant sodium persulfate was added to the obtained filtrate, the oxidant and copper smelting slag were in a mass ratio of 5:100, mechanically stirred for 6 hours, and the stirring speed was 9...

Embodiment 2

[0049] A kind of industrial copper smelting slag as raw material to prepare high-purity, high value-added Fe 2 o 3 Iron red method, the specific steps are:

[0050] After the industrial copper smelting slag is crushed and ground, take 100g of copper smelting slag and mix it with 500g of 20% dilute hydrochloric acid, then transfer it to a three-necked round-bottomed flask, raise the temperature to 98°C in an oil bath, condense and reflux for 10 hours, and the reaction is over After cooling to room temperature, the mixture solution was filtered, 5g of oxidant sodium peroxide was added to the obtained filtrate, the oxidant and copper smelting slag were in a mass ratio of 5:100, mechanically stirred for 6 hours, and the stirring speed was 800 rpm, and then the solution was allowed to stand 24h, after filtering and washing, 6.67g reduced iron powder was added to the solution, the reduced iron powder and copper smelting slag were added according to the mass ratio of 1:15, mechanica...

Embodiment 3

[0053] A kind of industrial copper smelting slag as raw material to prepare high-purity, high value-added Fe 2 o 3 Iron red method, the specific steps are:

[0054] After crushing and grinding the industrial copper smelting slag, mix 100g of copper smelting slag with 500g of dilute hydrochloric acid with a concentration of 25% and transfer it into a round-bottomed three-neck flask, raise the temperature to 98°C in an oil bath, condense and reflux for 24 hours, and the reaction is over After cooling to room temperature, the mixture solution was filtered, and 5g of oxidizing agent sodium perchlorate was added in the obtained filtrate, and the oxidizing agent and copper smelting slag were 5:100 according to the mass ratio, mechanically stirred for 6h, and the stirring speed was 1000 rpm, and then the solution was static Set aside for 24 hours, filter and wash, then add 6.67g of reduced iron powder to the solution, add reduced iron powder and copper smelting slag at a mass ratio ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com