A chemical treatment method for detoxification processing of cottonseed protein

A chemical treatment and cottonseed protein technology, applied in the field of cotton meal processing, can solve the problems of low dephenolization rate, solvent recovery and residue, high energy consumption, harsh fermentation conditions, etc., to meet the needs of industrial scale production, simple process flow, The effect of high protein recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

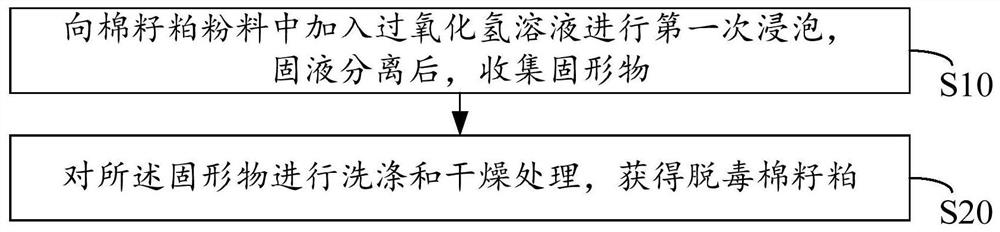

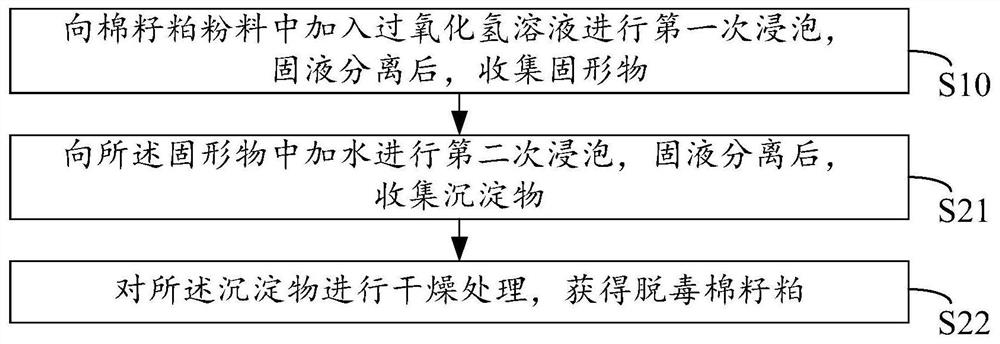

Method used

Image

Examples

Embodiment 1

[0044] (1) after mechanical comminution taking through a 30 mesh sieve dry cottonseed meal 5g, was added 25mL concentration of 3% hydrogen peroxide solution at pH 4.0, mixed evenly soaked 1.5h at 70 ℃ water bath, then centrifuge at 4000rpm in rpm for 5min, discarded the supernatant, collected solids;

[0045] (2) adding to the solid-liquid mass ratio of solids in tap water 1:10, at a temperature of 22 is immersed 4min deg.] C (to constantly stirred during immersion), and then centrifuged at 5min 4000rpm and discarded the supernatant was then repeat the soaking water, centrifugation step 1, the resulting supernatant was centrifuged acidic starch iodide test solution does not change color, the supernatant was discarded and the precipitate was collected;

[0046] (3) The precipitate is dried in a ventilated drying oven temperature of 50 deg.] C, the water content of the material to not more than 15%, cottonseed meal detoxification dried to give 4.3g.

Embodiment 2

[0048] (1) after mechanical comminution taking through a 50 mesh screen, dry cottonseed meal 5g, was added 10mL concentration of 1.5%, pH6.0 solution of hydrogen peroxide, mixed evenly soaked in a water bath at 80 ℃ 3h, then passed through the centrifuge at 4000rpm rpm for 10min, the supernatant was discarded, collected solids;

[0049] (2) adding to the solid-liquid mass ratio of solids in tap water 1:20, soaking at a temperature of 25 deg.] C 3min (to constantly stirred during immersion), and then centrifuged at 10min 4000rpm and discarded the supernatant was then repeat the soaking water, centrifugation step 1, the resulting supernatant was centrifuged acidic starch iodide test solution does not change color, the supernatant was discarded and the precipitate was collected;

[0050] (3) The precipitate is dried in a ventilated drying cabinet at 80 ℃ temperature, the water content of the material to not more than 15%, cottonseed meal detoxification dried to give 4.2g.

Embodiment 3

[0052] (1) after mechanical comminution taking through a 50 mesh screen, dry cottonseed meal 20g, was added 80mL concentration of 2.5% hydrogen peroxide solution, pH 8.0, mixed evenly soaked 8h at 50 ℃ water bath and then passed through a centrifuge at a rotation speed of 3000rpm from 15min, the supernatant was discarded, collected solids;

[0053] (2) adding to the solid-liquid mass ratio of solids in tap water 1:12, soaked at a temperature of 27 ℃ 2min (to constantly stirred during immersion), and then centrifuged at 3000 rpm for 15min and discarded the supernatant was then repeat the soaking water, centrifugation step three times, the resulting supernatant was centrifuged acidic starch iodide test solution does not change color, the supernatant was discarded and the precipitate was collected;

[0054] (3) The precipitate was under irradiation conditions of a temperature of 30 deg.] C sun dried, the material to a water content not higher than 15%, cottonseed meal detoxification ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com