Preparation method of transition metal sulfide composite nanometer material

A technology of composite nanomaterials and transition metals, which is applied in the field of preparation of transition metal sulfide composite nanomaterials, can solve the problems of energy density limiting the application of supercapacitors, achieve good pseudocapacitive characteristics and cycle stability, high application value, and preparation The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Preparation of ZIF-67 Nanomaterials

[0024] Dissolve cobalt nitrate hexahydrate (29.1 mg) and 2-methylimidazole (32.8 mg) in 15-25 mL of methanol respectively, then slowly add the cobalt nitrate solution into the 2-methylimidazole solution, stir at room temperature for 2 h, and The mixed solution was left standing at room temperature for 24 hours, the precipitate was collected by centrifugation, washed with methanol and ethanol respectively, and finally dried at 80°C for 24 hours to obtain the precursor ZIF-67 nanomaterial.

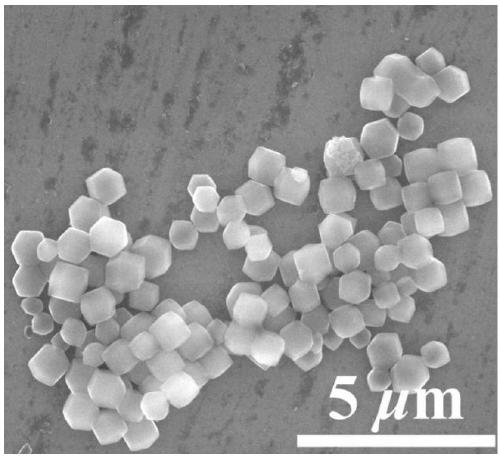

[0025] The morphology of the obtained ZIF-67 nanomaterials was characterized by scanning electron microscopy. Such as figure 1 As shown, the obtained ZIF-67 nanomaterial is a dodecahedron with a smooth surface, and the crystal size is about 700 nm.

Embodiment 2

[0027] Preparation of NiCo-LDH intermediate

[0028] Dissolve nickel nitrate hexahydrate (120 mg) in 20-25 mL of ethanol, then add 60 mg of ZIF-67 precursor into the above solution, and ultrasonicate for 5-20 min to make it uniformly dispersed. Stir the dispersion at room temperature for 10 h, centrifuge to collect the precipitate, wash with methanol and ethanol respectively, and finally dry at 80° C. for 24 h to obtain the NiCo-LDH intermediate nanomaterial.

Embodiment 3

[0030] Preparation of NiCo 2 S 4 @MoS 2 nanomaterials

[0031] The NiCo-LDH intermediate nanomaterial (25 mg) in Example 2 was dispersed in deionized water, and then added with a concentration of 20 mg / mL of thioacetamide solution 5 mL and a concentration of 10 mg / mL of sodium molybdate solution, fully After mixing, transfer to a reaction kettle, keep at 120° C. for 4 hours, and then keep at 200° C. for 8 hours. After the reaction, the product is collected by centrifugation and washing with water.

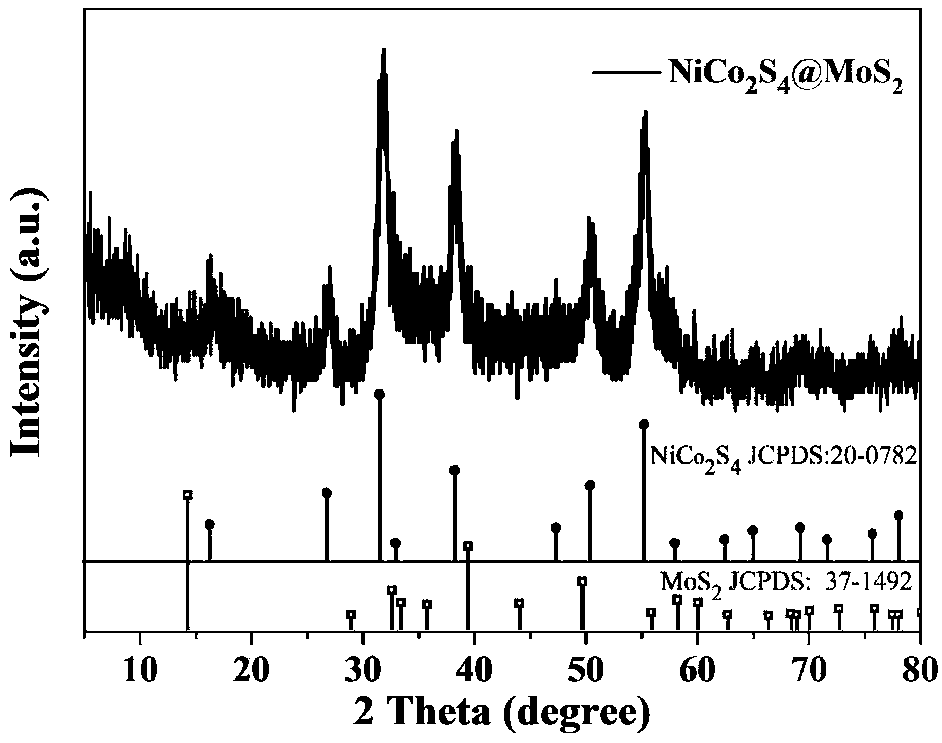

[0032] Its structure was analyzed by X-ray diffractometer, such as figure 2 As shown, the nanomaterial is NiCo in the cubic phase 2 S 4 , due to MoS 2 Low crystallinity and presence of small amounts, NiCo 2 S 4 @MoS 2 There is no obvious MoS in the diffraction pattern 2 diffraction peaks.

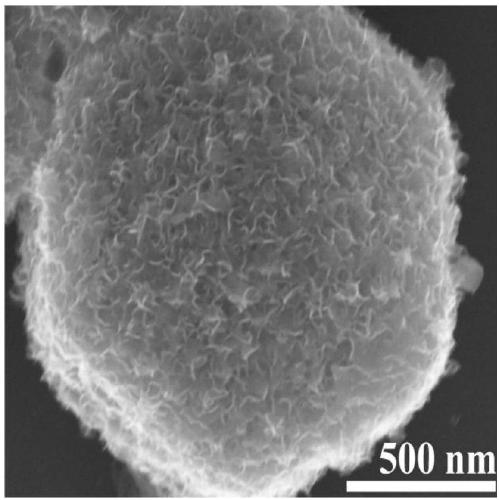

[0033] The resulting NiCo was characterized by scanning electron microscopy 2 S 4 @MoS 2 Morphology of nanomaterials. Such as image 3 As shown, the resulting NiCo 2 S 4 @MoS ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com