Nano-montmorillonite modified acrylic silicon/boron copper-free self-polishing type anti-fouling coating and preparation method thereof

A technology of nano-montmorillonite and non-toxic acrylic, which is applied in the direction of antifouling/underwater coatings, coatings, paints containing biocides, etc., can solve the problems of non-performing tin-free self-polishing antifouling coatings, etc., and achieve antifouling performance The effect of stability, good compatibility and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

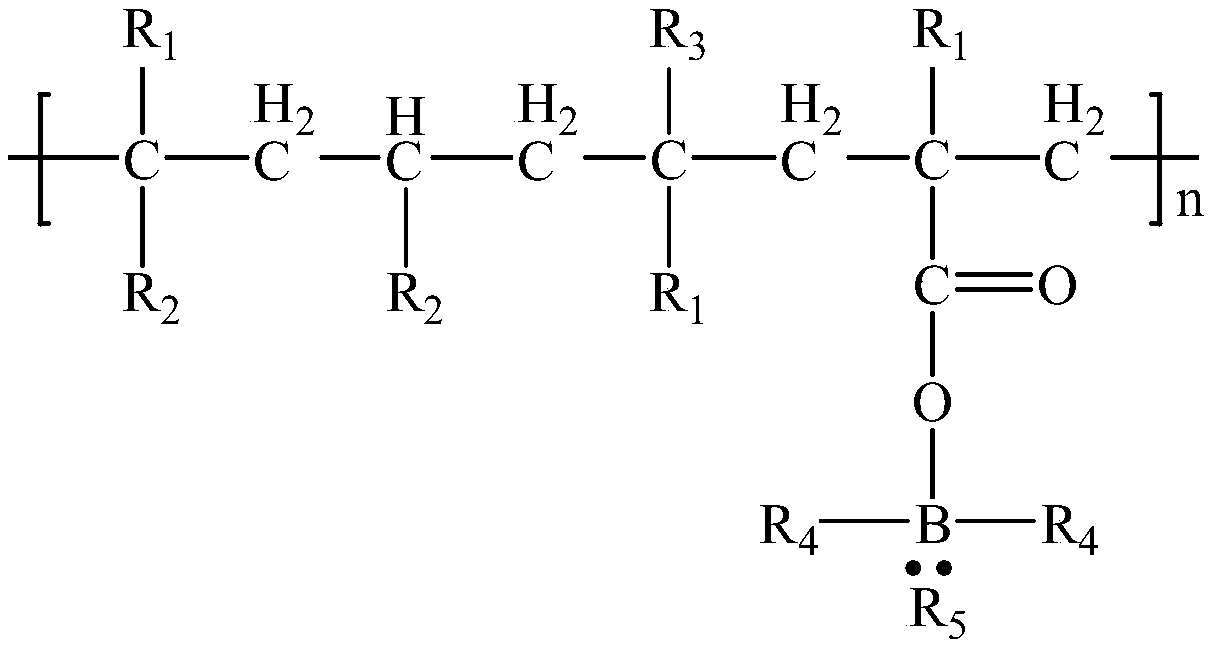

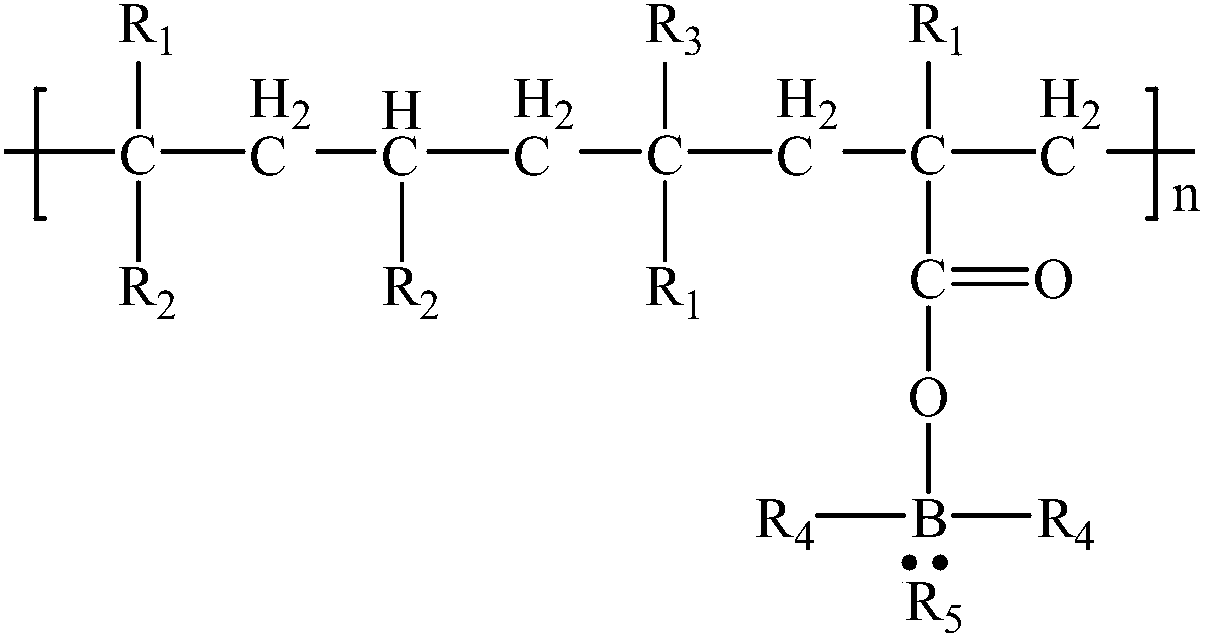

Image

Examples

Embodiment 1

[0037] A two-component solvent of 80 parts of xylene (Xylene) and 20 parts of absolute ethanol was added to a 500 mL four-neck round bottom flask, heated to 95-100° C., and condensed to reflux. Strong mechanical stirring. 1.5 parts each of azobisisobutyronitrile (AIBN) and azobisisoheptanonitrile (ABVN) and 30 parts of triisopropylsilane acrylate, 15 parts of methacrylic acid (MAA), 10 parts of methyl methacrylate (MMA), 15 parts of butyl acrylate (BA) to form a mixed solution, and then gradually add it dropwise into the reaction system under the protection of nitrogen. Acyl (BPO) in xylene. Finally, the reaction was continued for 1.5 hours to obtain an acrylic silicone resin (abbreviated as AASP, the same below).

[0038] Add 112 parts of xylene and 78 parts of acetone mixed solvent into a four-necked bottle, add 20 parts of pyridine triphenylborane, mix well, add 145 parts of acrylic silicone resin (AASP) prepared in the previous step, and react for 10 hours under the same...

Embodiment 2

[0040] A two-component solvent of 80 parts of xylene (Xylene) and 20 parts of n-butanol (BuOH) was added into a 500 mL four-neck round bottom flask, heated to 95-100 °C, and condensed to reflux. Strong mechanical stirring. 1.8 parts of azobisisobutyronitrile (AIBN) and 4.2 parts of azobisisovaleronitrile (AMBN) and 30 parts of methacryloxyamidotrimethylsilane, 10 parts of methacrylic acid (MAA), 15 parts Methyl methacrylate (MMA) and 25 parts of butyl acrylate (BA) were prepared as a mixed solution, and then gradually added dropwise to the reaction system under the protection of nitrogen for about 3 hours, and then continued to react for 2 hours, and then added 1.5 A solution of benzoyl peroxide (BPO) in xylene. Finally, the reaction was continued for 1.5h to obtain acrylic silicone resin (AASP).

[0041]Add 100 parts of xylene and 80 parts of tetrahydrofuran mixed solvent into a four-necked bottle, add 30 parts of triphenylboronoctadecylamine, mix well, add 150 parts of acr...

Embodiment 3

[0043] Weigh a certain amount of sodium-based montmorillonite and disperse it in water under high-speed stirring, raise the temperature to 80-100°C, add the intercalation agent dodecyldimethylphenylammonium bromide under strong stirring, and stir vigorously for a period of time After that, stir at a low speed and react for a period of time; filter with suction, wash the obtained white precipitate with deionized water until no bromide ions exist, put the obtained white precipitate in an oven and dry it at 60-80°C , ground, sieved, and set aside to obtain the modified nanometer montmorillonite with anti-algae property.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com