Preparation method of heavy metal adsorbent based on shrimp shell biomass charcoal with high specific surface area

A high specific surface area, biological adsorbent technology, applied in chemical instruments and methods, adsorbed water/sewage treatment, pathogenic microorganism wastewater treatment, etc. The preparation process is simple, the cost is low, and the heavy metal adsorption rate is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

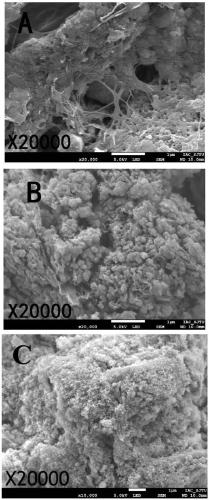

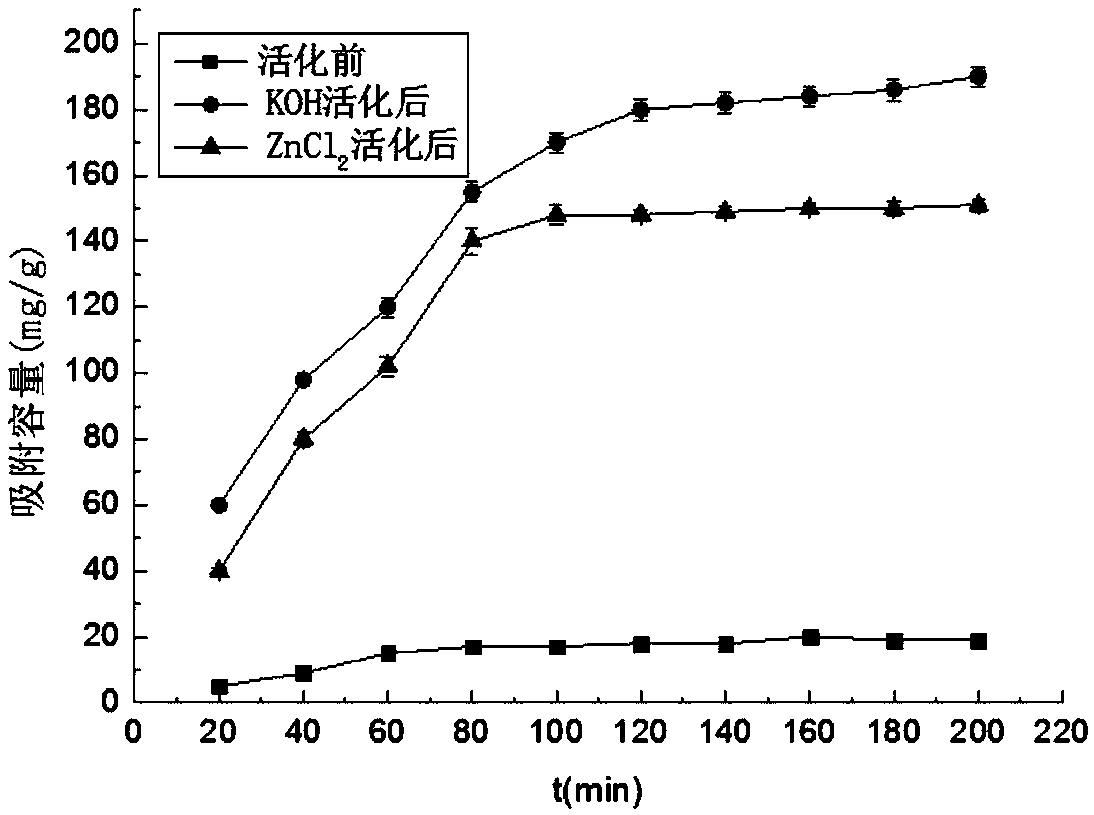

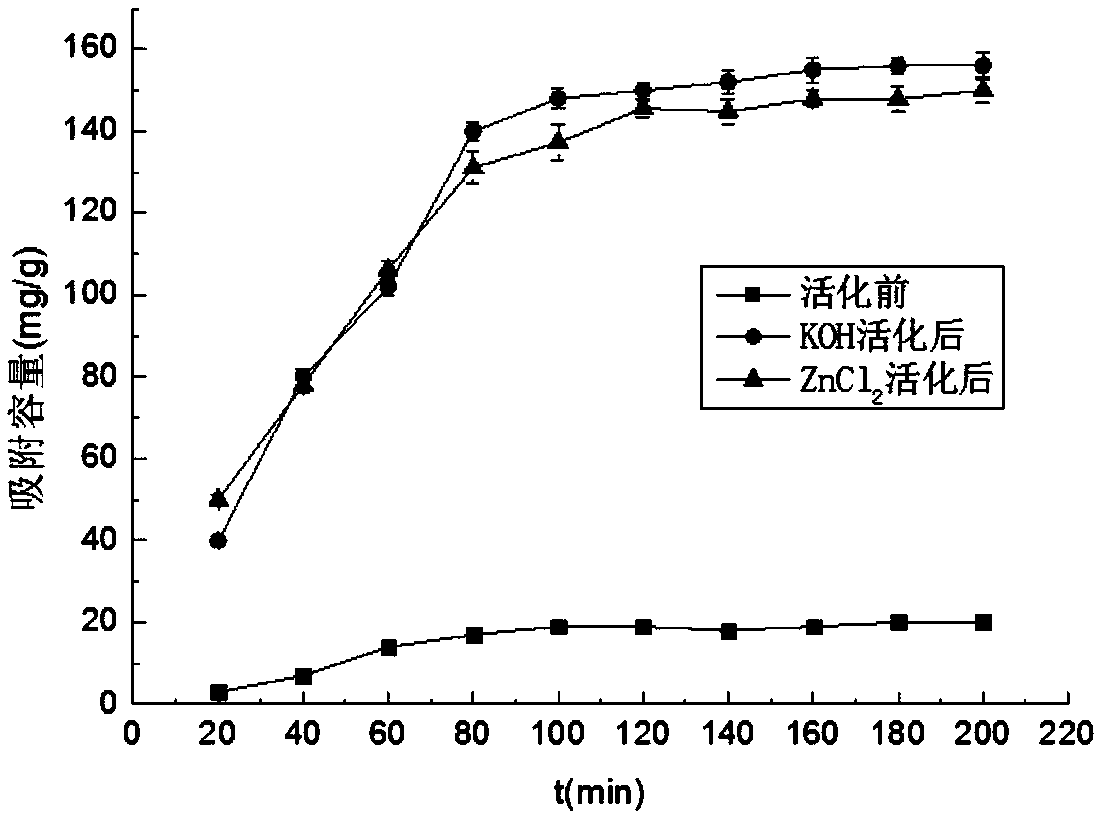

[0030] A kind of preparation method based on high specific surface area shrimp shell biochar comprises the steps:

[0031] The discarded Penaeus vannamei shrimp shells were repeatedly washed with water to remove various impurities, and dried for use; a square crucible containing 20 g of discarded Penaeus vannamei shrimp shells was placed in a tube furnace for calcining, and nitrogen gas was introduced at a flow rate of 100 mL / min, keep it for about 1h; after ensuring that there is an oxygen-free environment in the tube furnace, adjust the temperature to 900°C at a heating rate of 10°C / min, keep it warm for 3h, cool to room temperature, turn off the nitrogen, take it out, put it into a In a beaker of 1mol / L hydrochloric acid, stir for 1 hour with magnetic force, after suction filtration, wash with deionized water until the pH value of the solution is 7, then dry the sample at 105°C for 8 hours, then crush it, and pass it through a 100-mesh sieve , to obtain the shrimp shell-base...

Embodiment 2

[0035] A kind of preparation method based on high specific surface area shrimp shell biochar comprises the steps:

[0036] The discarded Penaeus vannamei shrimp shells were repeatedly washed with water to remove various impurities, and dried for use; a square crucible containing 20 g of discarded Penaeus vannamei shrimp shells was placed in a tube furnace for calcining, and nitrogen gas was introduced at a flow rate of 100 mL / min, keep it for about 1h; after ensuring that there is an oxygen-free environment in the tube furnace, adjust the temperature to 800°C at a heating rate of 10°C / min, keep it warm for 3h, cool to room temperature, turn off the nitrogen, take it out, put it into a In a beaker of 1mol / L hydrochloric acid, stir for 1 hour with magnetic force, after suction filtration, wash with deionized water until the pH value of the solution is 7, then dry the sample at 105°C for 8 hours, then crush it, and pass it through a 100-mesh sieve , to obtain the shrimp shell-ba...

Embodiment 3

[0041] A kind of preparation method based on high specific surface area shrimp shell biochar comprises the steps:

[0042] The discarded Penaeus vannamei shrimp shells were repeatedly washed with water to remove various impurities, and dried for use; a square crucible containing 20 g of discarded Penaeus vannamei shrimp shells was placed in a tube furnace for calcining, and nitrogen gas was introduced at a flow rate of 100 mL / min, keep it for about 1.5h; after ensuring an oxygen-free environment in the tube furnace, adjust the temperature to 800°C at a heating rate of 10°C / min, keep it warm for 2h, cool to room temperature, turn off the nitrogen, take it out, put it into the Put it in a beaker with 1mol / L hydrochloric acid, stir it magnetically for 1 hour, filter it with suction, wash it with deionized water until the pH value of the solution is 7, then dry the sample at 105°C for 12 hours, crush it, and pass it through 100 mesh Sieve to obtain the shrimp shell-based biosorbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com