Catalyst for preparing maleic anhydride through oxidation of n-butane and preparation method thereof

A catalyst, n-butane technology, used in physical/chemical process catalysts, chemical instruments and methods, organic chemistry, etc., can solve problems such as insignificant improvement, achieve prevention of aggregation, good selective oxidation, and fine grain size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

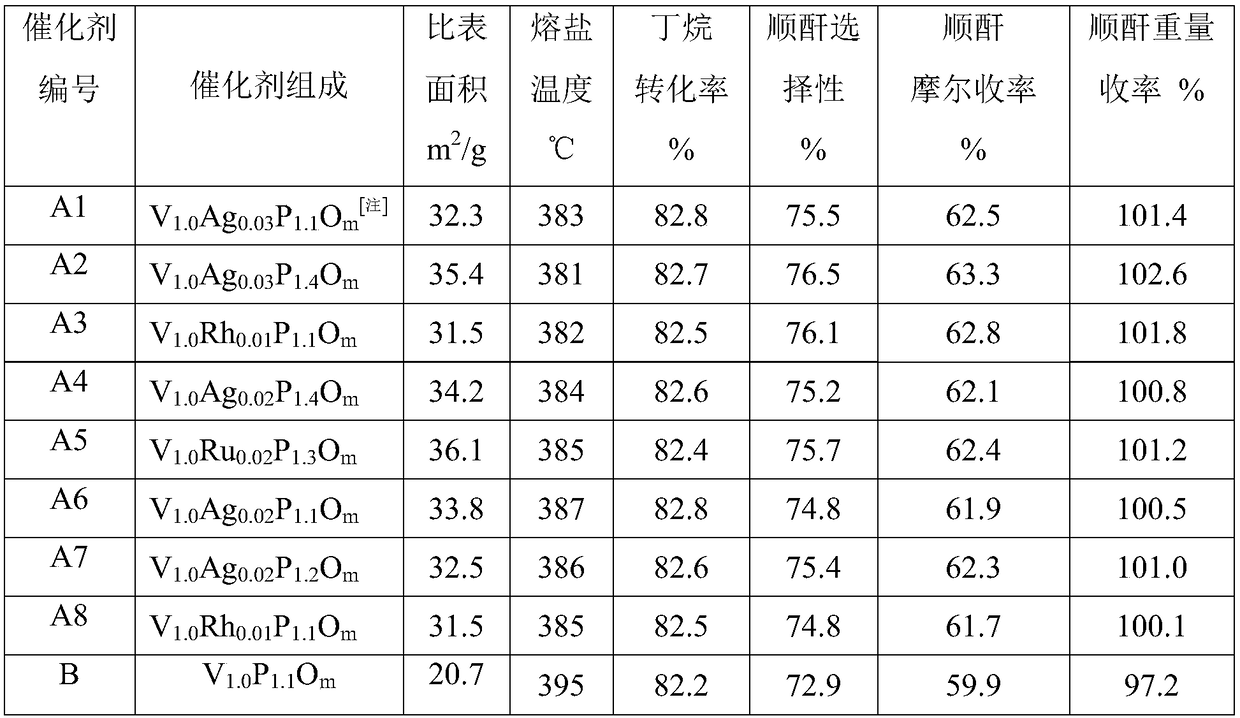

Examples

Embodiment 1

[0040] Add 2700g isobutanol, 600g benzyl alcohol, 456g vanadium pentoxide and 25.8g silver citrate into a reactor equipped with stirring, heating and condensing reflux device. Stir evenly, control the temperature at 110℃~120℃, Pressure: -10kPa~-20kPa, add 540g phosphoric acid at a constant speed within 2h, then continue to reflux for 5h at this temperature and pressure, cool and filter after the reaction, and dry the filter cake at 110℃~130℃ for 20h, then 300℃ It is calcined at ~320°C for 6h to obtain an active precursor. The active precursor is granulated into 10 mesh to 40 mesh, mixed with 3% graphite, compressed into a hollow cylinder with an outer diameter of 5 mm, an inner diameter of 2 mm, and a height of 5 mm. Then, the oxygen content is 9% to 11 at 460℃~480℃ Activated in an atmosphere of %% for 6h to obtain catalyst A1.

Embodiment 2

[0042] In a reactor equipped with stirring, heating and refluxing devices, add 3000g of isobutanol and 600g of benzyl alcohol, then add 396g of vanadium pentoxide and 22.3g of silver citrate, stir well, control the temperature at 110℃~120℃, Pressure: -10kPa~-20kPa, add 596g phosphoric acid at a constant speed within 3h, then continue to reflux for 5h at this temperature and pressure, cool and filter after the reaction, and dry the filter cake at 110℃~130℃ for 20h, then 320℃ It is calcined at ~340°C for 6h to obtain an active precursor. The active precursor is granulated into 15 mesh to 30 mesh, mixed with 2% graphite, compressed into a hollow cylinder with an outer diameter of 5 mm, an inner diameter of 2 mm, and a height of 5 mm. Then, the oxygen content is 9% to 11 at 460℃~480℃ Activated in an atmosphere of %% for 6h to obtain catalyst A2.

Embodiment 3

[0044] Add 3300g isobutanol, 660g benzyl alcohol, 456g vanadium pentoxide and 27g rhodium isooctanoate in a reactor equipped with stirring, heating and condensing reflux devices. Stir evenly, control the temperature at 110℃~120℃, pressure -10kPa~-20kPa, add 540g phosphoric acid at a constant rate within 2h, then continue to reflux for 5h at this temperature and pressure, cool and filter after the reaction, and dry the filter cake at 120℃~140℃ for 18h, and then at 320℃~ It is calcined at 340℃ for 6h to obtain the active precursor. The active precursor is granulated into 15 mesh to 30 mesh, mixed with 2% graphite, compressed into a hollow cylinder with an outer diameter of 5 mm, an inner diameter of 2 mm, and a height of 5 mm. Then, the oxygen content is 9% to 11 at 460℃~480℃ Activated in an atmosphere of %% for 6h to obtain catalyst A3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com