High-toughness high temperature resistant cable material

A cable material and high temperature resistant technology, applied in the field of high temperature resistant cable material, can solve the problems of reduced strength, thermal stability and anti-aging properties of cable materials, insufficient bonding strength, poor compatibilizer, etc., and achieve good anti-aging properties. , Excellent compatibility, the effect of improving dispersibility and compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

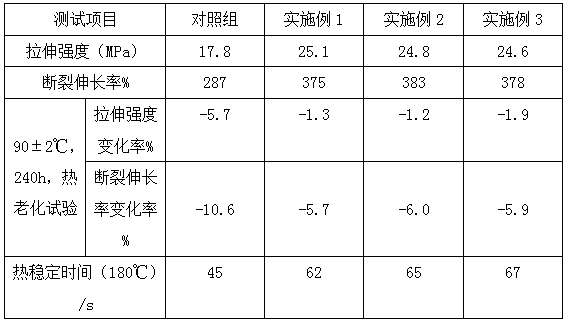

Examples

Embodiment 1

[0037] A high-toughness, high-temperature-resistant cable material, according to the number of parts by mass, the components of the cable material include: 105 parts of EPDM rubber, 13 parts of polyethylene resin, 6 parts of vulcanized silicone rubber, 6 parts of white carbon black, and 15.5 parts of thermal filler, 8 parts of toughened fiber, 7 parts of composite flame retardant, 1.8 parts of silane coupling agent, 2.5 parts of lubricating dispersant, and 3 parts of calcium-zinc composite stabilizer.

[0038] Among them, the heat-resistant filler is calcined kaolin, nano-alumina, N-phenylmaleimide and dibutyltin dilaurate according to the mass ratio of 20:8:3:5, and then mixed with 90% in the mixing kettle. The product obtained after the reaction was stirred at a temperature of ℃.

[0039] The composite flame retardant is a mixture of aluminum hydroxide, ammonium polyphosphate and antimony trioxide in a mass ratio of 4:1:2.

[0040] The lubricating dispersant is an equal mass ratio...

Embodiment 2

[0044] A high-toughness, high-temperature resistant cable material. According to the number of parts by mass, the components of the cable material include: 100 parts of EPDM rubber, 12 parts of polyethylene resin, 5 parts of vulcanized silicone rubber, 4 parts of white carbon black, and 14 parts of thermal filler, 7 parts of toughened fiber, 6 parts of composite flame retardant, 1 part of silane coupling agent, 2 parts of lubricating dispersant, 2 parts of calcium-zinc composite stabilizer.

[0045] Among them, the heat-resistant filler is calcined kaolin, nano-alumina, N-phenylmaleimide and dibutyltin dilaurate according to the mass ratio of 20:8:3:5, and then mixed with 80% in the mixing kettle. The product obtained after the reaction was stirred at a temperature of ℃.

[0046] The composite flame retardant is a mixture of aluminum hydroxide, ammonium polyphosphate and antimony trioxide in a mass ratio of 4:1:2.

[0047] The lubricating dispersant is an equal mass ratio mixture of...

Embodiment 3

[0051] A high-toughness, high-temperature resistant cable material. According to parts by mass, the components of the cable material include: 110 parts of EPDM rubber, 14 parts of polyethylene resin, 7 parts of vulcanized silicone rubber, 8 parts of white carbon black, and 17 parts of thermal filler, 9 parts of toughened fiber, 8 parts of composite flame retardant, 3 parts of silane coupling agent, 3 parts of lubricating dispersant, 4 parts of calcium-zinc composite stabilizer.

[0052] Among them, the heat-resistant filler is made by mixing calcined kaolin, nano alumina, N-phenylmaleimide and dibutyltin dilaurate in a mass ratio of 20:8:3:5, and then mixing them in a mixing kettle with 95% The product obtained after the reaction was stirred at a temperature of ℃.

[0053] The composite flame retardant is a mixture of aluminum hydroxide, ammonium polyphosphate and antimony trioxide in a mass ratio of 4:1:2.

[0054] The lubricating dispersant is an equal mass ratio mixture of glycer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com