Environmentally friendly efficient anti-corrosion water-based coating and synthesis method thereof

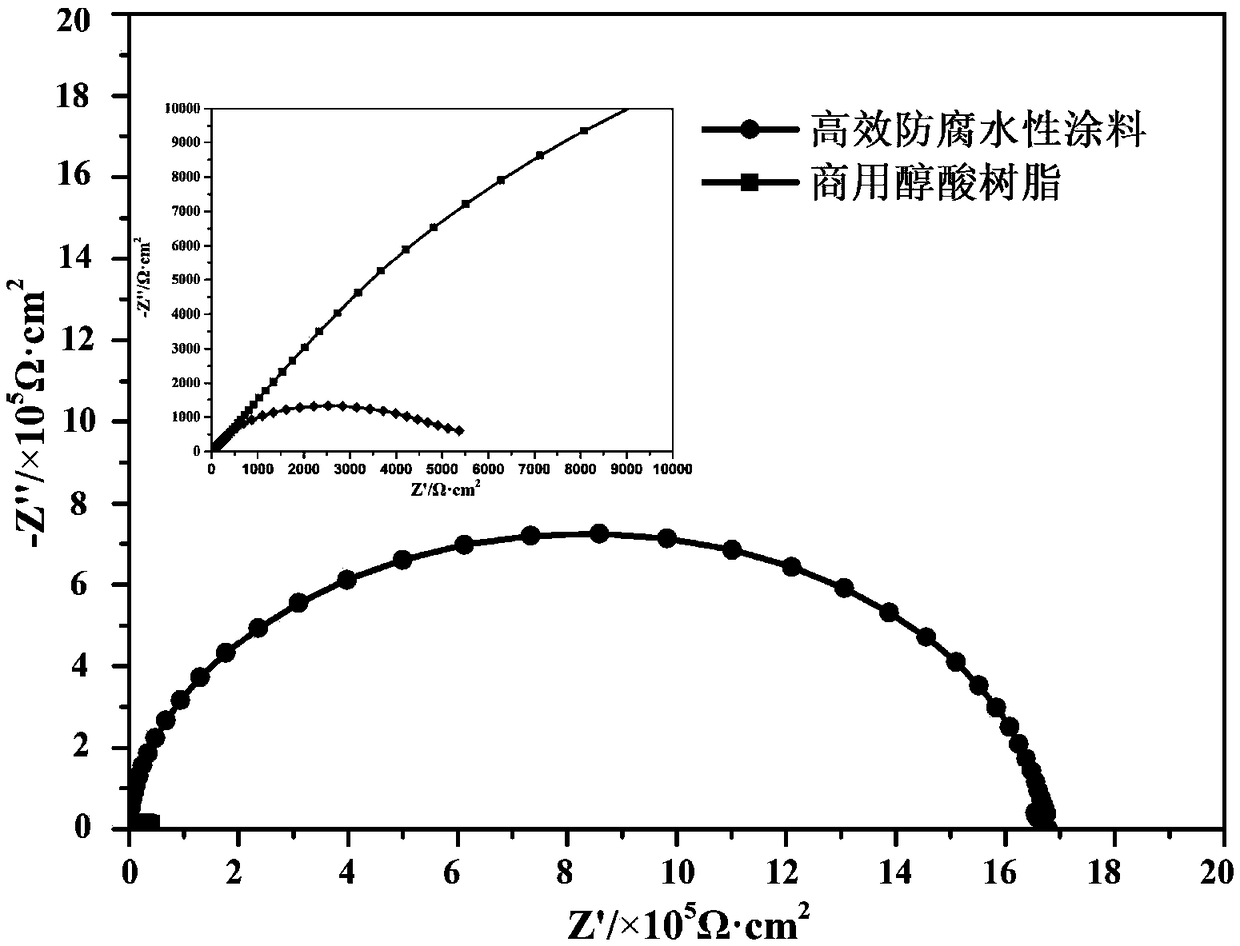

A water-based coating and an environmentally friendly technology, applied in anti-corrosion coatings, coatings, etc., can solve problems such as human health hazards and air pollution, achieve low VOC content, increase service life, and be environmentally friendly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1. Preparation of component A:

[0034] 1. The synthetic method of polydopamine modified polyaniline / graphene oxide composite,

[0035] 1) Preparation of polyaniline / graphene oxide composite: 0.03g graphene oxide and 0.5g aniline monomer were mixed in 1M 100mL perchloric acid solution, 0.76g ammonium persulfate was dissolved in 1M 10mL perchloric acid solution, and the After pretreatment at -10°C, quickly add it to the above reaction solution, react at -10°C for 12 hours, centrifuge the obtained emerald green flocculent precipitate, dry at 60°C, and grind to obtain polyaniline / graphite oxide ene complex.

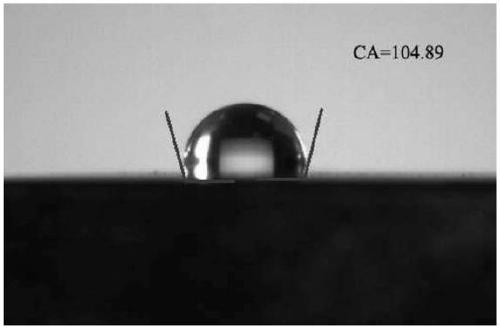

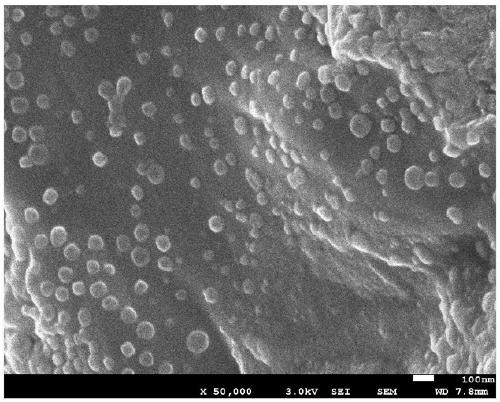

[0036] 2) Modify the polyaniline / graphene oxide composite: dissolve 0.02g polyaniline / graphene oxide composite in Tris-hydrochloric acid buffer solution with pH=8.5, add 0.04g dopamine hydrochloride, and react at room temperature for 24 hours, centrifuged, dried at 60°C, and ground to obtain a polydopamine-modified polyaniline / graphene oxide composite (see and 1). ...

Embodiment 2

[0044] 1. Preparation of component A:

[0045] 1. A method for preparing polydopamine-modified polyaniline / graphene oxide composites, including preparation and modification of polyaniline / graphene oxide composites.

[0046] 1) Preparation of polyaniline / graphene oxide composite: Mix 0.045g graphene oxide and 0.75g aniline monomer in 100mL perchloric acid solution, dissolve 1.0g ammonium persulfate in 1M 10mL perchloric acid solution, and quickly add In the above reaction solution, the polymerization reaction was carried out at room temperature for 18 hours, and the obtained emerald green flocculent precipitate was centrifuged, dried at room temperature, and ground to obtain the polyaniline / graphene oxide composite.

[0047] 2) Modify the polyaniline / graphene oxide composite: dissolve 0.02g polyaniline / graphene oxide composite in Tris-hydrochloric acid buffer solution with pH=8, add 0.03g dopamine hydrochloride, and react at room temperature for 18 hours, centrifuged, dried at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com