Cyanic acid ester compound and method for producing same, resin composition, cured article, prepreg, sealing material, fiber-reinforced composite material, adhesive agent, metal foil-clad laminate plate, resin sheet, and printed wiring board

A technology of cyanate compound and resin composition, applied in the directions of printed circuit, printed circuit parts, aldehyde/ketone condensation polymer adhesive, etc., can solve the problem of low thermal expansion, high glass transition temperature, multi-layer printing Circuit board warpage and other problems, to achieve the effect of high practicability, excellent thermal conductivity, and high glass transition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0250] Hereinafter, this embodiment will be further described in detail based on examples. However, this embodiment is not particularly limited to the following examples.

[0251] (Determination of OH group (g / eq.) equivalent of hydroxy aromatic compound)

[0252] The OH group equivalent (g / eq.) was determined by the pyridine-acetyl chloride method in accordance with JIS-K0070.

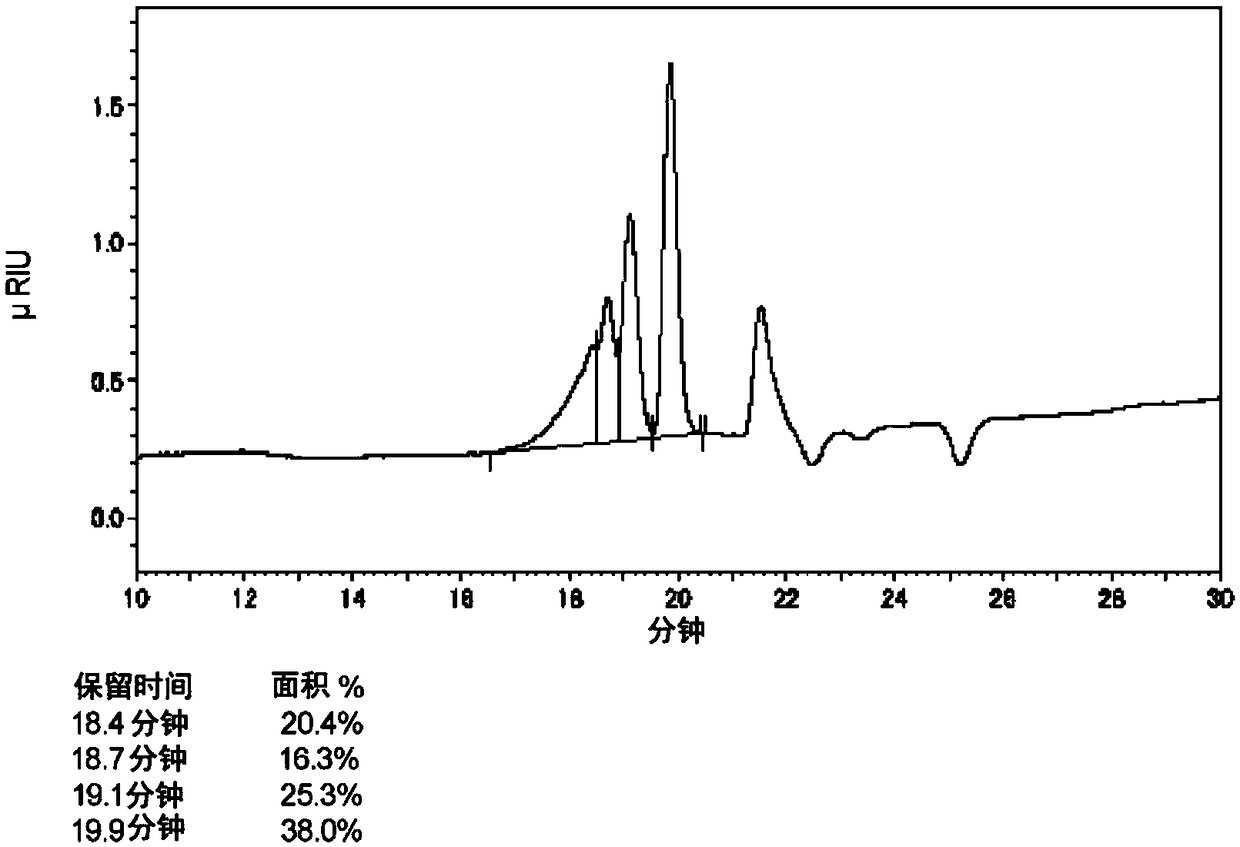

[0253] (Measurement of weight average molecular weight (Mw) of cyanate compound)

[0254] 10 μL of a solution obtained by dissolving 1 g of a cyanate compound in 100 g of tetrahydrofuran (solvent) was injected into a high-performance liquid chromatograph (High-speed liquid chromatograph LaChrom (registered trademark) Elite manufactured by Hitachi High-Technologies Corporation), and analyzed. The column is TSKgel GMH manufactured by Tosoh Corporation HR -M (length 30cm×inner diameter 7.8mm) 2, the mobile phase is tetrahydrofuran, the flow rate is 1mL / min, and the detector is RI. The weight average ...

Embodiment 2

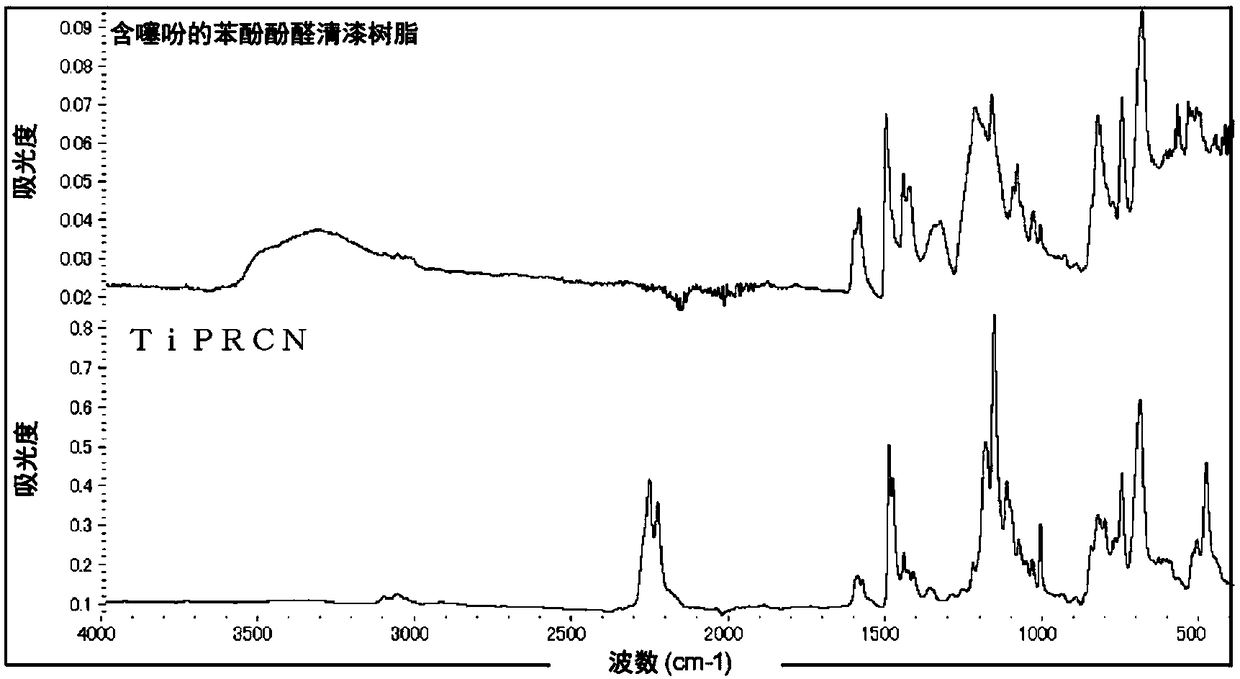

[0270]

[0271] Put 100 parts by mass of the cyanate compound TiPRCN obtained in Example 1 into an eggplant-shaped flask, heat and melt at 150° C., degas it with a vacuum pump, pour it into a mold described in JIS-K7238-2-2009, and place Put in an oven, heat at 180° C. for 3 hours, and then heat at 250° C. for 3 hours to cure, and obtain a cured product with 1 side 100 mm and thickness 2 mm.

Embodiment 3

[0294] 50 mass parts of cyanate compound TiPRCN obtained in Example 1, 50 mass parts of biphenyl aralkyl type epoxy resin (trade name " NC-3000-FH ", manufactured by Nippon Kayaku Co., Ltd.) and molten dioxide 100 parts by mass of silicon (trade name "SC2050MB", manufactured by Admatechs Co., Ltd.) was mixed to obtain a varnish. The varnish was diluted with methyl ethyl ketone, dip-coated on a 0.1 mm-thick E-glass woven cloth, and heated and dried at 165° C. for 4 minutes to obtain a prepreg with a resin content of 50% by mass.

[0295] Eight sheets of the obtained prepregs were stacked, and 12 μm-thick electrolytic copper foil (trade name "3EC-M3-VLP", manufactured by Mitsui Metal Mining Co., Ltd.) was placed on the upper and lower sides of the stacking direction, and the pressure was 40kgf / cm 2 1. Laminate molding was performed at a temperature of 230° C. for 120 minutes to obtain a copper-clad laminate (metal foil-clad laminate) with an insulating layer thickness of 0.8 mm....

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| weight-average molecular weight | aaaaa | aaaaa |

| weight-average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com