A preparation g-c 3 no 4 Method of composite carrier with carbon fiber

A composite support, g-c3n4 technology, applied in chemical instruments and methods, catalyst supports, chemical/physical processes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

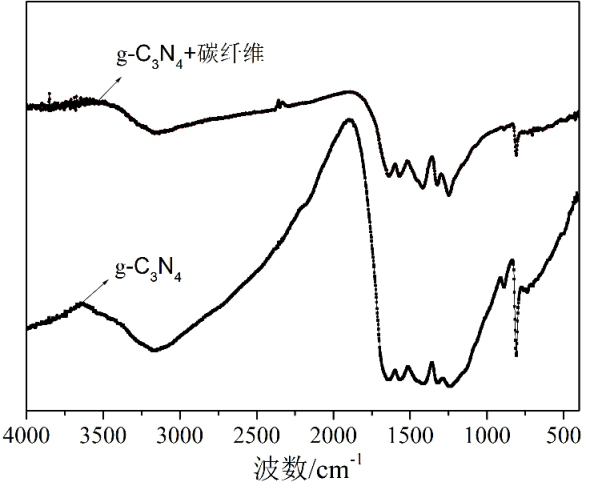

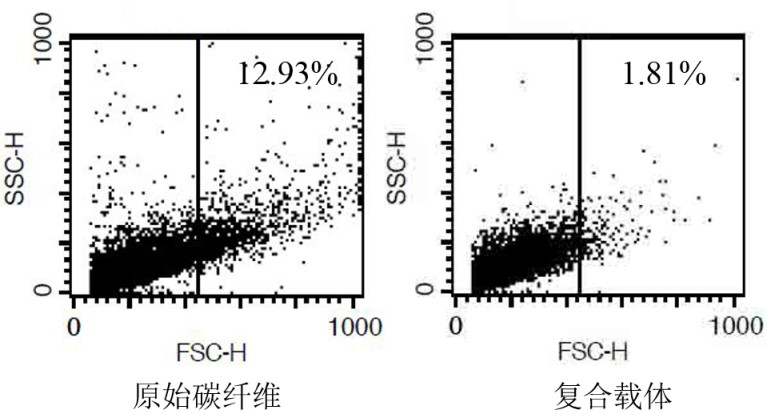

[0022]Take 0.5g of melamine and 1.5g of polyacrylonitrile, add it to 14 mL of N,N-dimethylamide reagent, mix well, and the spinning conditions are: voltage 15kV, pushing speed 1mL / h, needle point distance The distance between the receiver is 10cm, and the receiver is aluminum foil, and the spun fiber is obtained by spinning. The spun fiber is pre-oxidized at 280°C for 4h, and carbonized at 700°C for 4h, and then the carbonized composite carrier Put it into a quartz boat containing an appropriate amount of water, so that the water just submerges the composite carrier, and treat it for 1 hour under the conditions of an ozone concentration of 30 mg / L and an ultraviolet power of 300W to obtain g -C 3 N 4 and carbon fiber composite carrier.

[0023] g -C 3 N 4 Composite carrier with carbon fiber for multi-batch fermentation of immobilized Aspergillus niger to produce calcium gluconate:

[0024] Inoculate Aspergillus niger into the solid medium, after culturing for 48 hours, w...

Embodiment 2

[0029] Take 0.4 g of urea and 2.5 g of polyacrylonitrile, add to 22 mL of N,N-dimethylamide and tetrahydrofuran reagent (V N,N-二甲基酰胺 :V 四氢呋喃 =17:5), after mixing evenly, under the conditions of spinning conditions: voltage 18kV, pushing speed 1 mL / h, distance between the needle tip and the receiver 8 cm, and the receiver is made of aluminum foil, spin to obtain Spin the fiber, pre-oxidize the spun fiber at 290°C for 2 hours, and carbonize it at 750°C for 3 hours, then put the carbonized composite carrier into a quartz boat containing 20% hydrogen peroxide to make the hydrogen peroxide Just submerged the composite carrier, and treated for 1h under the conditions of ozone concentration of 20 mg / L and ultraviolet power of 200W, that is g -C 3 N 4 and carbon fiber composite carrier.

[0030] g -C 3 N 4 and carbon fiber composite carrier for the multi-batch fermentation of immobilized Micrococcus rosea to produce trehalose:

[0031] Inoculate Micrococcus rosea into the se...

Embodiment 3

[0036] Take 0.5g of nitrogen-containing organic matter (mass ratio of urea and melamine = 2:3) and 3g of polyacrylonitrile, add it to 28mL of N,N-dimethylamide, mix well, and the spinning condition is: voltage 21kV, the pushing speed is 1 mL / h, the distance between the needle tip and the receiver is 10cm, and the receiver is aluminum foil, the spun fiber is obtained by spinning, the spun fiber is pre-oxidized at 290°C for 2h, and the spun fiber is pre-oxidized at 750°C Carry out carbonization for 3 hours, and then put the carbonized composite carrier into a quartz boat with 30% hydrogen peroxide, so that the hydrogen peroxide just submerges the composite carrier, and treat it for 1.5 h under the condition of ozone concentration of 15 mg / L to obtain g -C 3 N 4 and carbon fiber composite carrier.

[0037] g -C 3 N 4 and carbon fiber composite carrier for immobilized Pseudomonas putida multi-batch fermentation to produce trehalose:

[0038] Inoculate Pseudomonas putida into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com