Preparation method of a foamed nickel-based carbon onion array embedded with metal oxides

A technology of oxides and carbon onions, applied in nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problems of general stability, reduced electrochemical performance, low energy density, etc., and achieve inhibition volume Effects of swelling, improving electrical conductivity, and increasing chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

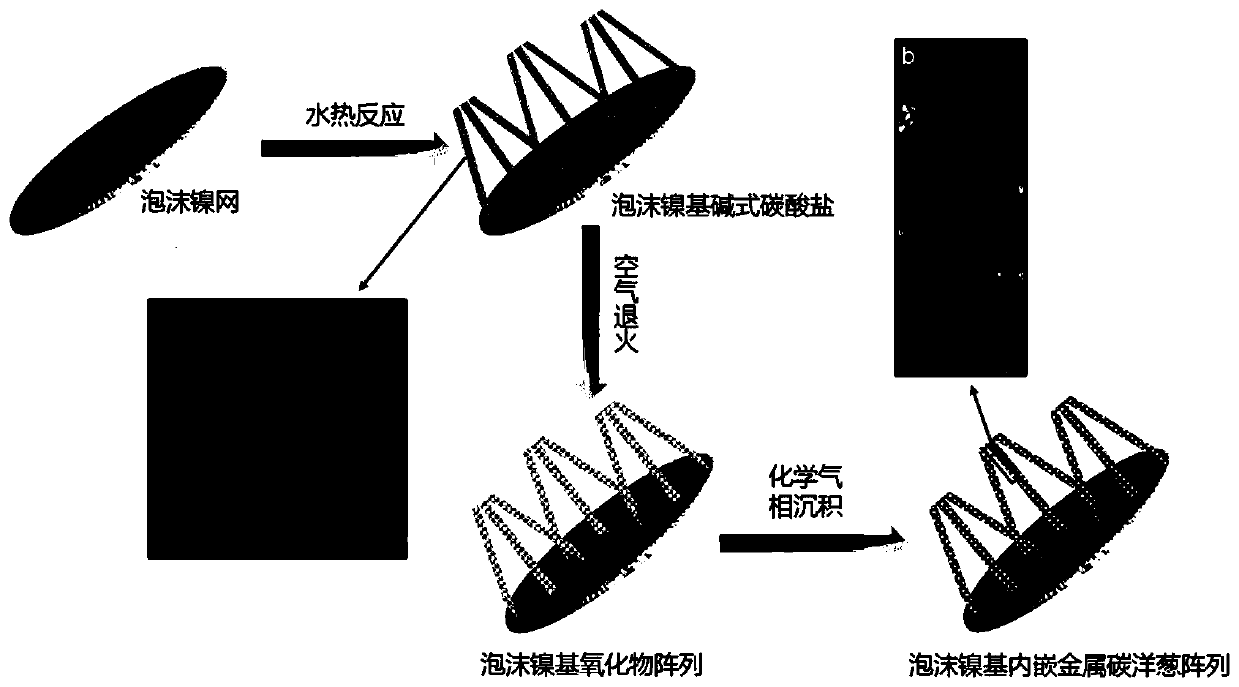

[0033] Such as Figure 1-2 As shown, the present invention provides a method for preparing a foam nickel-based embedded metal oxide carbon onion array, which is characterized in that it comprises the following steps:

[0034] Step 1. Add the raw materials nitrate, ammonium fluoride, and urea into a polytetrafluoroethylene-lined reactor filled with deionized water, place the foamed nickel disc on the liquid surface of the reactor, and place the foamed nickel disc on the liquid surface of the reactor. The top is covered with adhesive tape, and the closed reactor is placed in a constant temperature drying oven for hydrothermal reaction;

[0035] Step 2. After the hydrothermal reaction is completed, a foamed nickel disc with a basic carbonate nanowire array is obtained, which is cleaned several times and placed in a muffle furnace for annealing to obtain a foamed nickel-based oxide nanowire array;

[0036] Step 3. Place the foamed nickel-based oxide nanowire array in a horizontal...

Embodiment 10

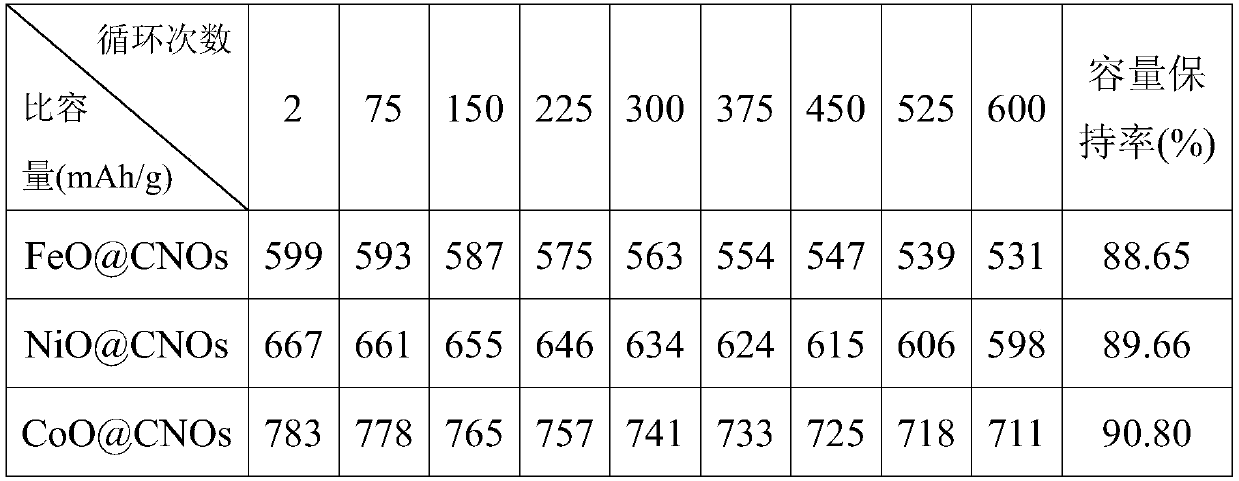

[0060] A foam nickel-based FeO@CNOs array, the implementation steps are as follows:

[0061] Weigh 2 parts of ferric nitrate, 6 parts of ammonium fluoride, and 10 parts of urea in molar ratio and add them to a polytetrafluoroethylene-lined reactor filled with 2000 parts of deionized water. Take a nickel foam disk with a radius of 6mm and wash it with absolute ethanol and dilute hydrochloric acid for 30 minutes, then use a tablet machine to press its thickness to 0.4mm, place it on the liquid surface of the reaction kettle, and coat its top with polytetrafluoroethylene tape . The closed reaction kettle was placed in a constant temperature drying oven for hydrothermal reaction.

[0062] Take out the foamed nickel disc loaded with the basic iron carbonate nanowire array, wash it with deionized water and absolute ethanol for 3-5 times, and then place it in a muffle furnace and anneal at 200°C for 2h in an air atmosphere , to prepare foamed nickel-based xFeO·yFe 2 o 3 array of ...

Embodiment 11

[0065] A foam nickel-based NiO@CNOs array, the implementation steps are as follows:

[0066] Weigh 2 parts of nickel nitrate, 4 parts of ammonium fluoride, and 10 parts of urea in molar ratio and add them to a polytetrafluoroethylene-lined reactor filled with 2500 parts of deionized water. Take a nickel foam disk with a radius of 5mm and wash it with absolute ethanol and dilute hydrochloric acid for 30 minutes, then use a tablet machine to press its thickness to 0.5mm and place it on the liquid surface of the reaction kettle, and coat the top with polytetrafluoroethylene tape . The closed reaction kettle was placed in a constant temperature drying oven for hydrothermal reaction.

[0067] Take out the foamed nickel disc loaded with the basic nickel carbonate nanowire array, wash it with deionized water and absolute ethanol for 3-5 times, and then place it in a muffle furnace and anneal at 300°C for 2h in an air atmosphere , The NiO foamed nickel-based nanowire arrays were pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com