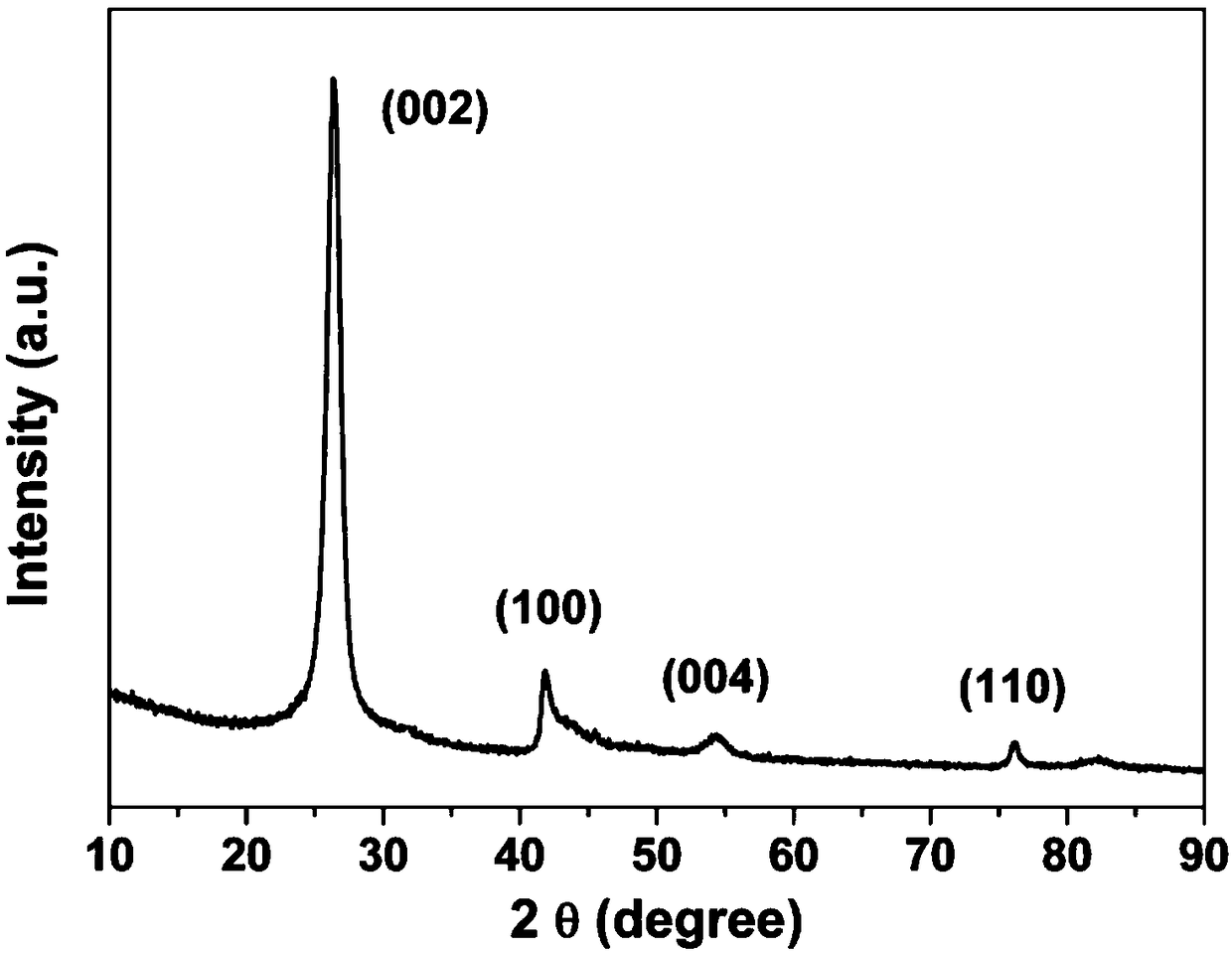

Three-dimensional porous boron nitride composite material for air purification and preparation method thereof

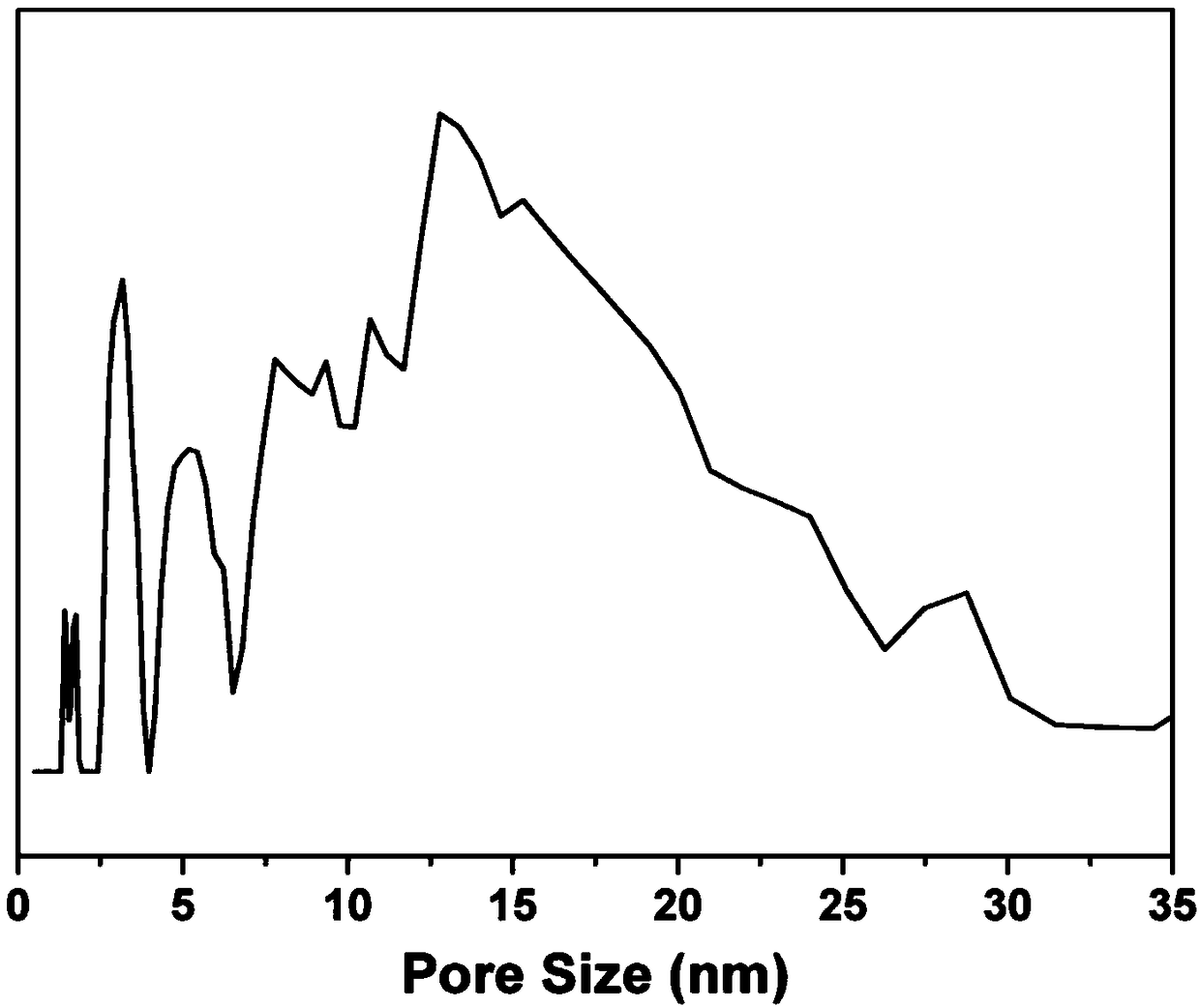

A three-dimensional porous and composite material technology, applied in chemical instruments and methods, separation methods, physical/chemical process catalysts, etc., can solve the problems of insufficient catalyst performance, inability to fully satisfy air purification, weak chemical stability, etc., to achieve The effect of excellent regeneration and reuse ability, excellent chemical stability and wide pore size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Weigh 1 part of boric acid and 0.01 part of melamine, add boric acid and melamine to 1 part of aqueous solution, and then completely dissolve boric acid and melamine in water by stirring; (2) Add 1 part of sodium chloride into the mixed aqueous solution, stirred to dissolve sodium chloride in water, and then heated the resulting mixed solution to 70°C until the water in the mixed solution was completely evaporated to obtain a white solid; (3) the product obtained in (2) was dissolved in nitrogen Heating to 700°C under protection, keeping it warm for 0.5 hours, after the end of keeping warm, lowering the temperature to room temperature under nitrogen protection to obtain a white solid; (4) impregnating the product obtained in (3) with an initial concentration of 0.01 mol / L In sodium hydroxide solution at 1°C, keep it for 0.1 hour; (5) filter the mixed solution obtained in (4), place it in a vacuum drying oven at 5°C, and dry it for 1 hour to obtain a three-dimensional...

Embodiment 2,3

[0037] Change the consumption of step (1) melamine in Example 1 into 1 part and 100 parts respectively, and other operations are all the same as in Example 1, and the product obtained is the same as in Example 1.

Embodiment 4、5

[0039] Change the consumption of step (1) water into 500 parts, 1000 parts respectively in the embodiment 1, and other each operation is all identical with embodiment 1, obtains product with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com