Method for preparing yellow or green silicon quantum dots

A technology of silicon quantum dots and green, which is applied in the field of preparing yellow or green silicon quantum dots, can solve the problems of difficult preparation of yellow or green silicon quantum dots, high requirements for equipment and low quantum yield, and achieve good water solubility and easy operation. Environmentally friendly, cheap and easy-to-get raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] (1) Dissolve 0.0068g of sodium citrate, 0.0011g of catechol and 0.206g of N-aminoethyl-γ-aminopropyltrimethoxysilane in 20ml of ultrapure water, and stir for 30min under the protection of nitrogen .

[0047] (2) Transfer the mixed solution in step (1) to a hydrothermal reaction kettle, and place it in an electric constant temperature blast drying oven for hydrothermal reaction at 130°C for 4h (before heating, you can use nitrogen or argon or other protective The gas is discharged from the air in the hydrothermal reaction kettle), and a yellow silicon quantum dot solution is obtained.

[0048] (3) After mixing the solution in step (2) with acetonitrile at a volume ratio of 1:4, centrifuge at 8000 rpm for 10 min, remove the supernatant, and freeze-dry to obtain solid silicon quantum dots.

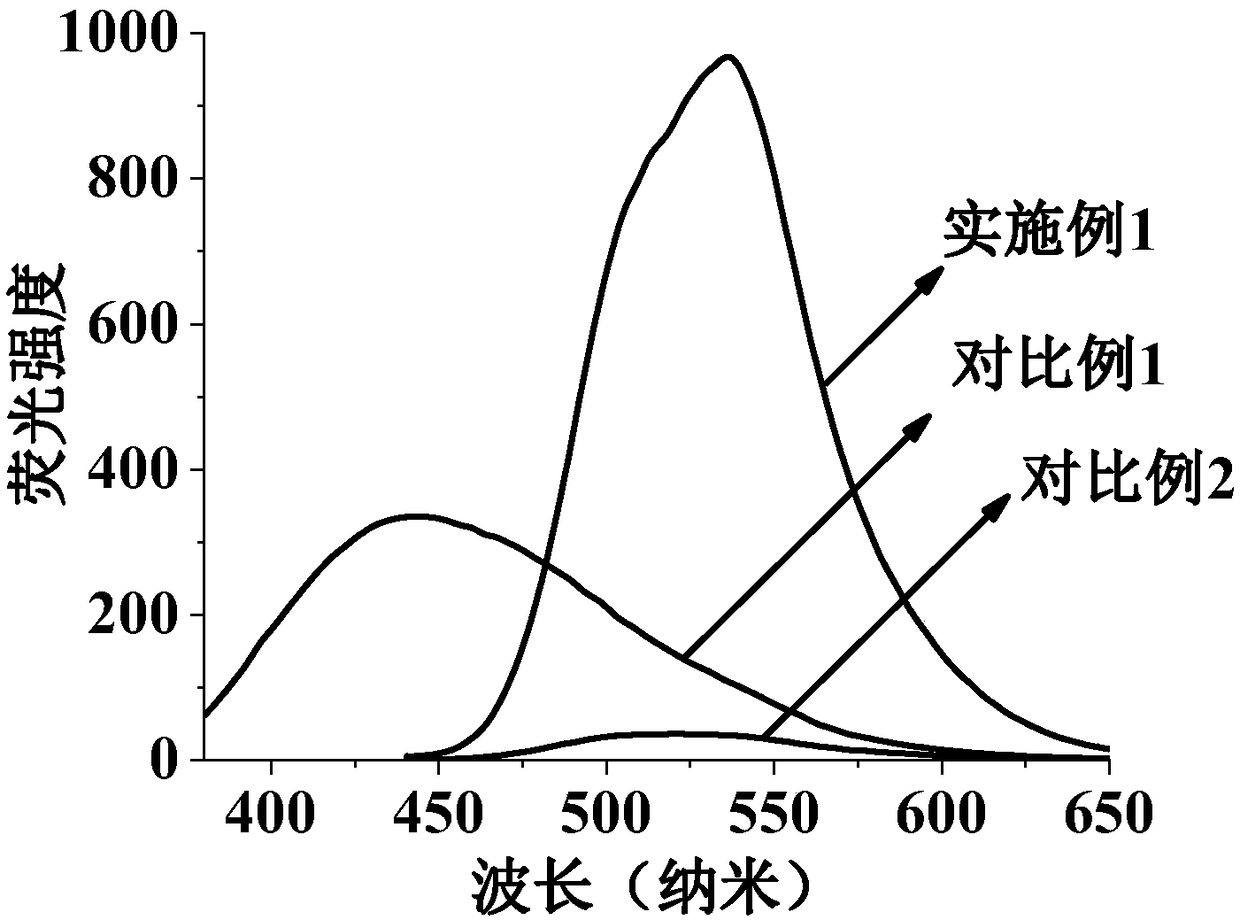

[0049] Rhodamine 6G dissolved in ethanol was used as a reference (quantum yield = 95%). The quantum yield of silicon quantum dots was calculated by comparing the ratio of fluorescenc...

Embodiment 2

[0054] (1) Dissolve 0.0068g of sodium citrate, 0.0011g of catechol and 0.206g of N-aminoethyl-γ-aminopropyltrimethoxysilane in 20ml of ultrapure water, and stir for 30min under the protection of nitrogen .

[0055] (2) Transfer the mixed solution in step (1) to a hydrothermal reaction kettle, and place it in an electric constant temperature blast drying oven for hydrothermal reaction at 150°C for 5h (before heating, you can use nitrogen or argon or other protective The gas is discharged from the air in the hydrothermal reaction kettle), and the green silicon quantum dot solution is obtained.

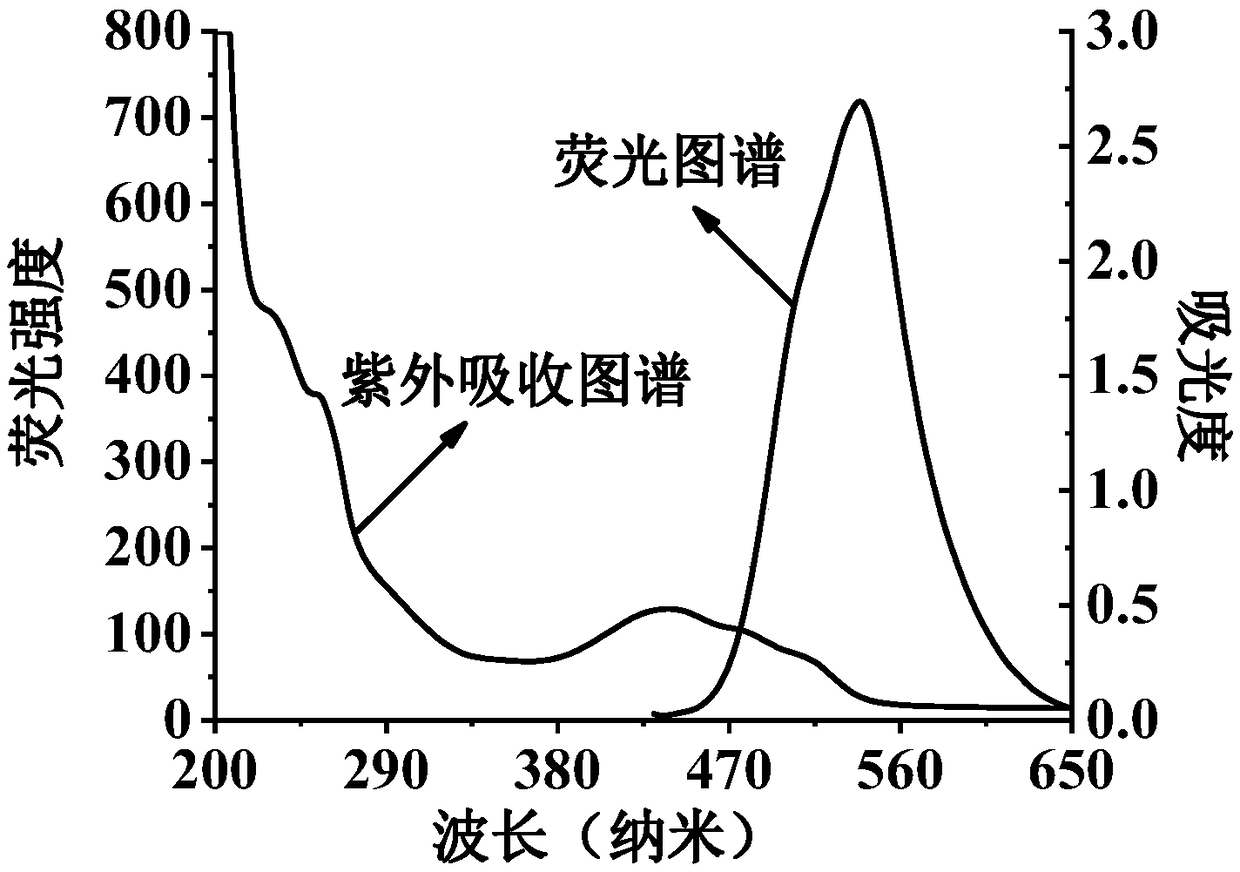

[0056] (3) After mixing the solution in step (2) with acetonitrile at a volume ratio of 1:4, centrifuge at 8000 rpm for 10 min, remove the supernatant, and freeze-dry to obtain solid silicon quantum dots. image 3 It is the fluorescence spectrum and the ultraviolet-visible light spectrum of the green quantum dot synthesized in embodiment 2. It can be seen from the figure that at the op...

Embodiment 3

[0058] (1) Dissolve 0.0068g of thiourea, 0.000275g of resorcinol and 1.03g of 3-aminopropyltrimethoxysilane in 10ml of ultrapure water, and stir for 5min under the protection of nitrogen.

[0059] (2) Transfer the mixed solution in step (1) to a hydrothermal reaction kettle, and place it in a Weibo hydrothermal reaction apparatus for hydrothermal reaction at 130°C for 2h (before heating, you can use nitrogen or argon, etc. to protect The gas is discharged from the air in the hydrothermal reaction kettle), and a yellow silicon quantum dot solution is obtained.

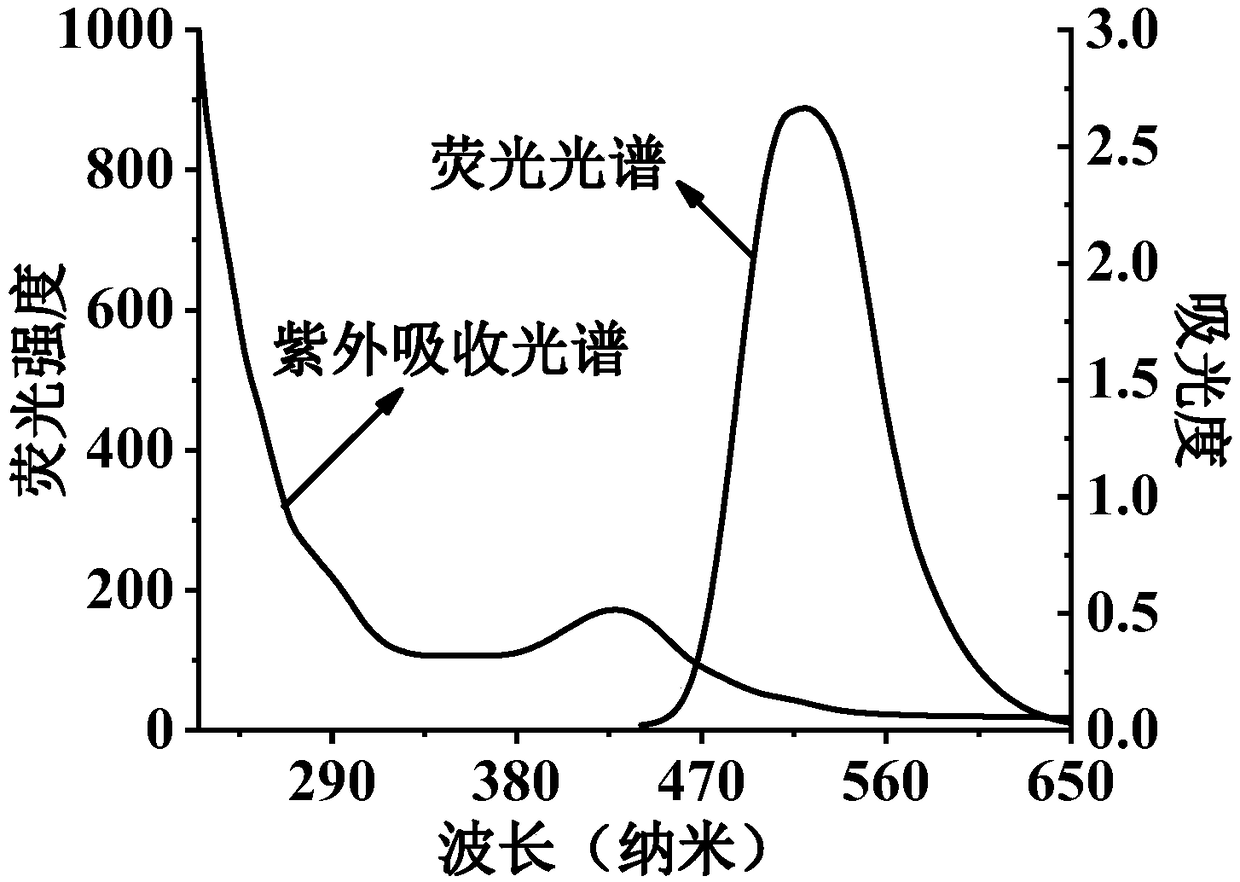

[0060] (3) After mixing the solution in step (2) with dimethyl sulfoxide at a volume ratio of 1:2, centrifuge at 10,000 rpm for 10 min, remove the supernatant, and freeze-dry to obtain solid silicon quantum dots. Figure 4 It is the fluorescence spectrum of the yellow quantum dots synthesized in Example 3. It can be seen from the figure that at the optimal excitation wavelength of 420nm, the emission peak of the silico...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Emission wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com