A monolithic porous dual-effect non-noble metal catalyst for water full-electrolysis and a synthetic method

A non-precious metal and synthesis method technology, applied in the field of monolithic porous double-effect non-precious metal full electrolysis water catalyst and its synthesis, can solve the problems of single catalytic function, poor stability, performance degradation, etc., achieve low energy consumption and reduce system complexity degree and manufacturing cost, and the effect of versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1 Preparation method of composite nano catalyst based on MXene and NiFe-LDH

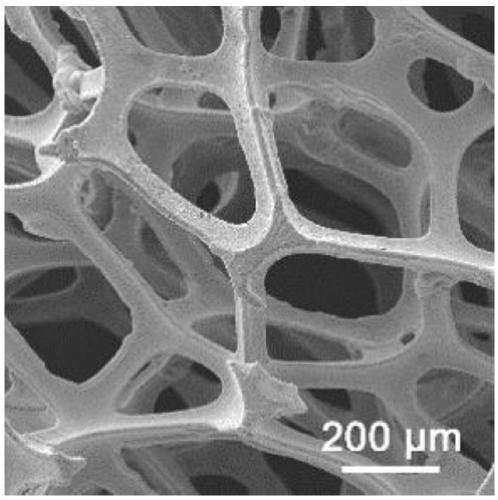

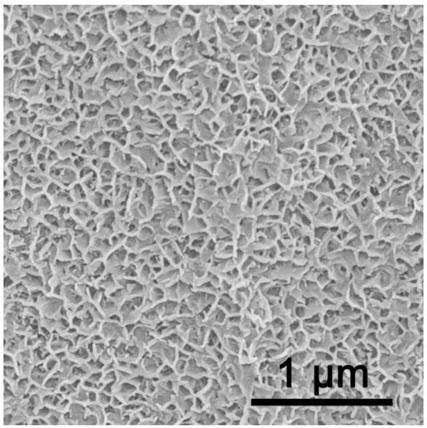

[0033] 1) Soak the foamed nickel into MXene dispersion, the concentration of MXene dispersion is 3mg mL -1 After being soaked for 30 minutes at room temperature, vacuum drying was carried out to obtain a foamed nickel electrode coated with MXene. The thickness of the MXene layer was about 300nm.

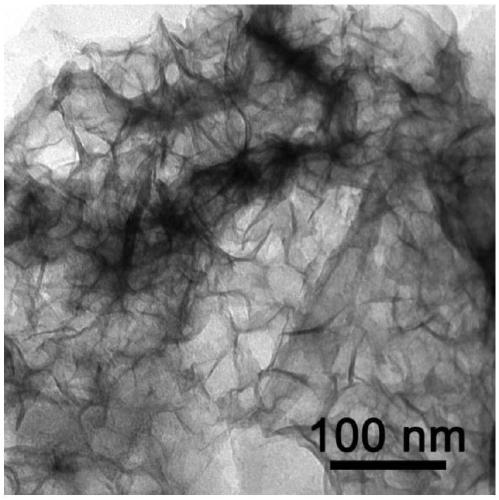

[0034] 2) The MXene-coated nickel foam prepared in step 1) is directly used as the working electrode, the platinum sheet is the counter electrode, the Ag / AgCl electrode is the reference electrode, and the electrolyte is 6 mol L -1 Of nickel nitrate and 6mol L -1 For the mixed solution of ferric nitrate, the voltage used for electrodeposition is -1V and the time is 300s. NiFe-LDH nanometers with a size of about 200-300nm are grown vertically on the surface of the MXene sheet, and the load is 0.2mg cm -2 .

Embodiment 2

[0035] Example 2 Preparation method of composite nano catalyst based on MXene and NiV-LDH

[0036] 1) Soak the foamed nickel into MXene dispersion, the concentration of MXene dispersion is 5mg mL -1 After being immersed for 30 minutes at room temperature, vacuum drying was carried out to obtain a foamed nickel electrode coated with MXene. The thickness of the MXene layer was about 400nm.

[0037] 2) The MXene-coated nickel foam prepared in step 1) is directly used as the working electrode, the platinum sheet is the counter electrode, the Ag / AgCl electrode is the reference electrode, and the electrolyte is 9 mol L -1 Nickel nitrate and 3mol L -1 For the mixed solution of vanadium trichloride, the voltage used for electrodeposition is -0.8V and the time is 360s. NiV-LDH nanosheets with a size of about 100-200nm are grown vertically on the surface of the MXene sheet, and the load is 0.2mg cm -2 .

Embodiment 3

[0038] Example 3 Preparation method of composite nano catalyst based on MXene and NiCo-LDH

[0039] 1) Soak the foamed nickel into MXene dispersion, the concentration of MXene dispersion is 8mg mL -1 After immersing for 30 minutes at room temperature, vacuum drying is used to obtain a foamed nickel electrode coated with MXene. The thickness of the MXene layer is about 550 nm.

[0040] 2) The MXene-coated nickel foam prepared in step 1) is directly used as the working electrode, the platinum sheet is the counter electrode, the Ag / AgCl electrode is the reference electrode, and the electrolyte is 6 mol L -1 Nickel nitrate and 3mol L -1 For the mixed solution of cobalt nitrate, the voltage used for electrodeposition is -1V and the time is 60s. NiCo-LDH nanosheets with a size of about 50-100nm are grown vertically on the surface of the MXene sheet, and the load is 0.05mg cm -2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com