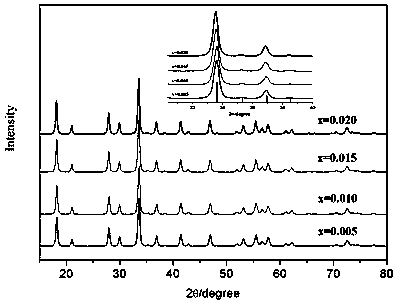

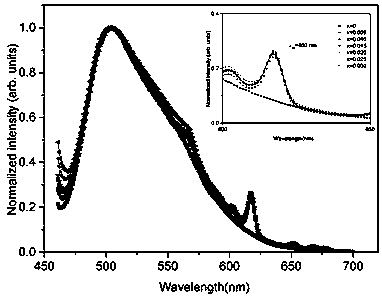

Microwave preparation method of Ce and Sm co-doping Lu3Al5O12 nanometer fluorescent powder

A technology of lu3al5o12 and nano-phosphor, which is applied in the field of microwave preparation of Ce, Sm co-doped Lu3Al5O12 nano-phosphor, can solve the problems of long holding time, complicated operation, low product purity, etc. Fast speed and improved color rendering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A kind of Ce, Sm co-doped Lu of the present invention 3 al 5 o 12 The microwave preparation method of nano-fluorescent powder uses metal nitrate as an oxidizing agent and glycine as a reducing agent, including the following steps:

[0034] (1) Prepare the precursor solution, the steps are as follows:

[0035] A, prepare cerium nitrate solution and nitrate solution, take by weighing cerium nitrate and dissolve in water according to stoichiometric ratio, be mixed with cerium nitrate solution; Take cerium nitrate and dissolve in nitric acid and water according to stoichiometric ratio, be mixed with nitrate solution;

[0036] b. Weigh Lu according to the stoichiometric ratio 2 o 3 Put it in a beaker and dissolve it in nitric acid in a constant temperature water bath at 40-80°C to form a transparent lutetium nitrate solution;

[0037] C, take by weighing aluminum nitrate, glycine according to stoichiometric ratio and join in the lutetium nitrate solution after being dis...

Embodiment 1

[0053] (1) Preparation of precursor solution:

[0054] Weigh 1.9535g (0.0045mol) of cerium nitrate hexahydrate, dissolve it in 28.0465g water, then Ce 3+ The concentration of the solution is 0.00015mol / g (a.q.); Weigh 1.5696g (0.0045mol) of oxide oxide and 2.62g of concentrated nitric acid, fully react under the heating condition of 80 ℃, add water to dilute to the total solution quality is 30g, then Sm 3+ The concentration of Lu2O3 is 0.0003mol / g (a.q.); Weigh 1.7907g (0.0045mol) Lu2O3 Five parts, put in 5 beakers, dissolve in 2.62g nitric acid under the condition of constant temperature water bath 80 ℃, form transparent lutetium nitrate solution;

[0055] Weigh each five parts of aluminum nitrate 5.6270g and glycine 0.9008g, dissolve them in water respectively, and add in the lutetium nitrate solution; drop 0.6g of configured cerium nitrate solution into each of the five parts of lutetium nitrate solution, and follow the chemical formula The stoichiometric ratio was dropped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com