Sealing material for construction and preparation method thereof

A sealing material and construction technology, applied in the direction of chemical instruments and methods, other chemical processes, adhesive types, etc., can solve problems such as large differences in surface properties of components, harmful construction personnel, uneven smoothness, etc., to achieve The effect of reducing the probability of waterproof failure, simplifying the construction steps, and making the steps easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

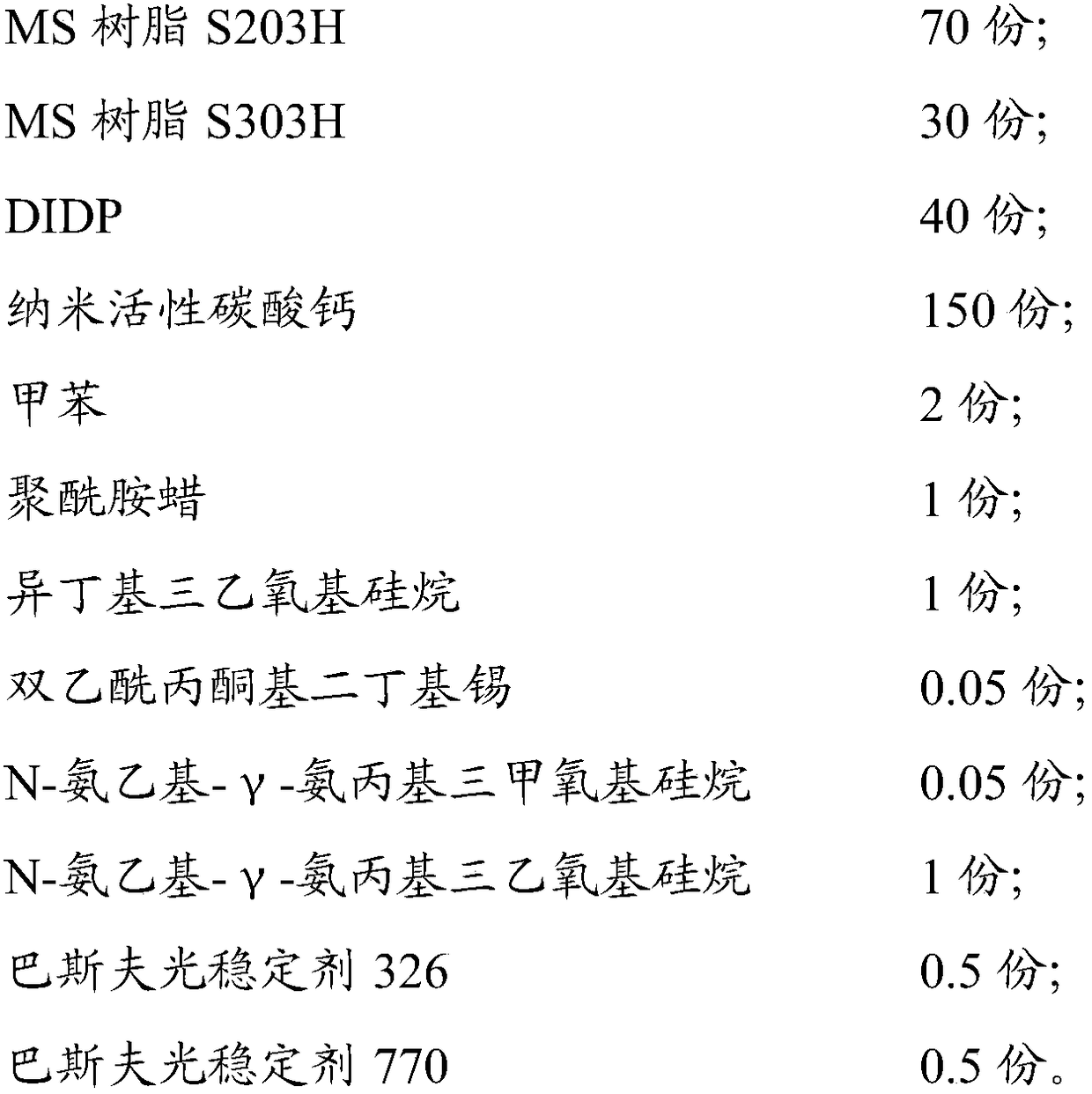

[0036] The raw material composition of the building sealing material described in this embodiment, in parts by weight, includes:

[0037]

[0038] The preparation method of above-mentioned construction sealing material, comprises the following steps:

[0039] (1) dehydrating the nano-active calcium carbonate under vacuum at 120°C for 3 hours and then cooling to room temperature;

[0040] (2) Mix MS resin S203H, MS resin S303H, DIDP, dehydrated nano-active calcium carbonate, polyamide wax, BASF light stabilizer 326 and BASF light stabilizer 770 under a vacuum of 0.09MPa~0.1MPa;

[0041] (3) Add toluene, isobutyltriethoxysilane, dibutyltin diacetylacetonate, N-aminoethyl-γ-aminopropyltrimethoxysilane, N-aminoethyl-γ-aminopropyl trimethoxysilane Ethoxysilane, and then stirred for 10 minutes under a vacuum degree of 0.06 MPa to 0.08 MPa, and discharged to obtain the sealing material.

[0042] Among them, the above-mentioned S203H resin and S303H resin are produced by KANEKA c...

Embodiment 2

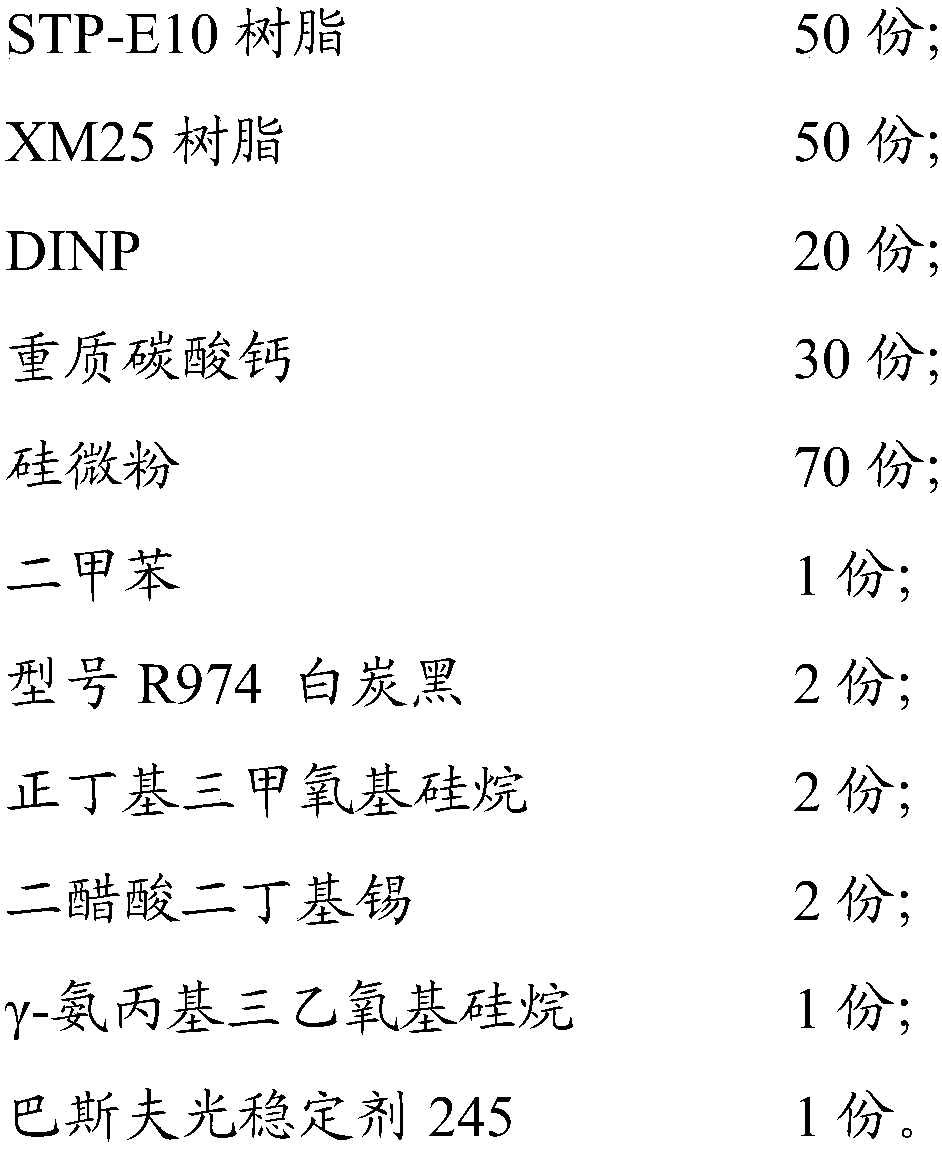

[0044] The raw material composition of the building sealing material described in this embodiment, in parts by weight, includes:

[0045]

[0046] The preparation method of above-mentioned construction sealing material, comprises the following steps:

[0047] (1) dehydrating heavy calcium carbonate and silicon micropowder under vacuum at 120°C for 3 hours and then cooling to room temperature;

[0048] (2) Mix STP-E10 resin, XM25 resin, DINP, dehydrated heavy calcium carbonate, silicon micropowder, white carbon black, and BASF light stabilizer 245 in a vacuum of 0.09MPa to 0.1MPa;

[0049] (3) After adding xylene, n-butyltrimethoxysilane, dibutyltin diacetate, and γ-aminopropyltriethoxysilane, stir for 10 minutes under a vacuum of 0.06MPa to 0.08MPa, and then discharge the material to obtain the Sealing material.

[0050] The above-mentioned STP-E10 resin and XM25 resin are produced by WACKER Company, DIDP is diisodecyl phthalate, and all raw materials are commercially ava...

Embodiment 3

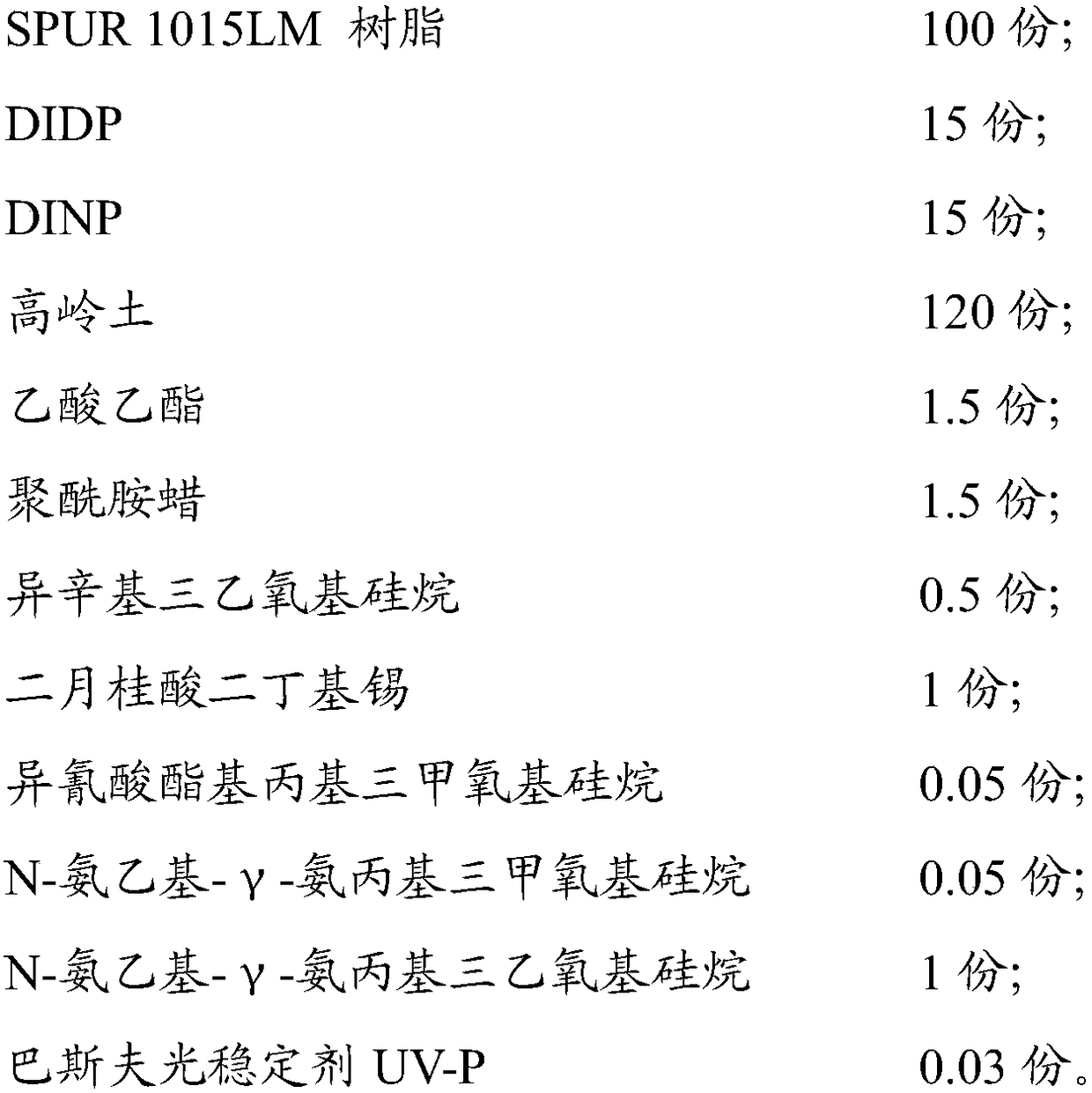

[0052] The raw material composition of the sealing material for construction described in this implementation, in parts by weight, includes:

[0053]

[0054] The preparation method of above-mentioned construction sealing material, comprises the following steps:

[0055] (1) dehydrating kaolin under vacuum at 120°C for 3 hours and cooling to room temperature;

[0056] (2) Mix SPUR1015LM resin, DIDP, DINP, dehydrated kaolin, polyamide wax, and BASF light stabilizer UV-P in a vacuum of 0.09MPa to 0.1MPa;

[0057] (3) Add ethyl acetate, isooctyltriethoxysilane, dibutyltin dilaurate, isocyanatopropyltrimethoxysilane, N-aminoethyl-γ-aminopropyltrimethoxysilane, N- The aminoethyl-γ-aminopropyltriethoxysilane is stirred for 10 minutes under a vacuum degree of 0.06MPa-0.08MPa, and the material is discharged to obtain the sealing material.

[0058] The above-mentioned SPUR 1015LM resin is produced by MOMENTIVE, DIDP is diisodecyl phthalate, and DINP is diisononyl phthalate; all raw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com