Hybrid crosslinked dynamic polymer

A hybrid cross-linking and polymer technology, applied in the field of smart polymers, can solve the problems of performance and application limitations, lack of dynamics, covalent interpenetrating network cannot be repaired, etc., to achieve high value, diverse performance, excellent circular effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

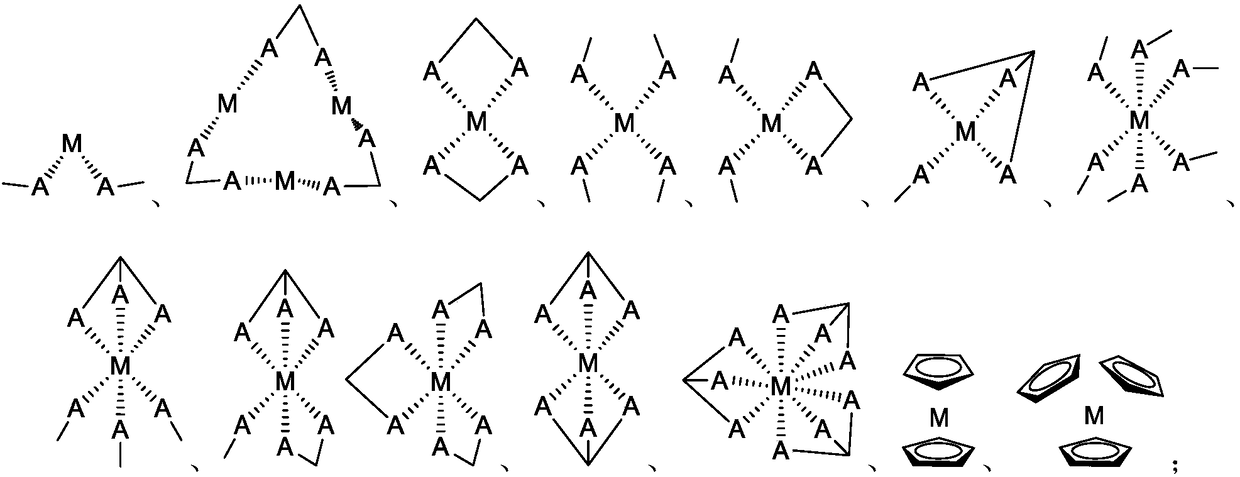

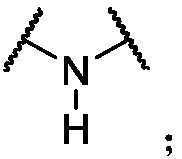

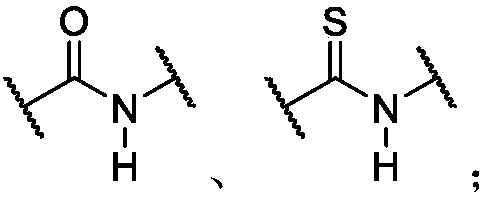

Method used

Image

Examples

preparation example Construction

[0137] In the preparation process of dynamic polymer, three methods are mainly used to foam the dynamic polymer: mechanical foaming method, physical foaming method and chemical foaming method.

[0138] Among them, the mechanical foaming method is to introduce a large amount of air or other gases into the emulsion, suspension or solution of the polymer by means of strong stirring during the preparation process of the dynamic polymer to make it a uniform foam, and then undergo physical Or chemical changes make it into a foam material. In order to shorten the molding cycle, air and emulsifiers or surfactants can be added.

[0139] Among them, the physical foaming method uses physical principles to achieve polymer foaming during the preparation of dynamic polymers. It generally includes but is not limited to the following methods: (1) Inert gas foaming method, namely Press the inert gas into the molten polymer or paste material under pressure, and then reduce the pressure and increase...

Embodiment 1

[0197] 21g of 5-vinylpyrimidine and 35g of acrylamide were mixed and dissolved in 200mL of toluene and then added to the No. 1 reactor. Then 2g of azobisisobutyronitrile (AIBN) was added. The temperature was raised to 95°C and the reaction was stirred for 6h. Then add 30g of toluene diisocyanate, continue to stir the reaction for 1h, remove the excess solvent, transfer the reactant to the wide-mouthed No. 2 reactor, add 100mL of dibutyl phthalate and 2mL 0.2 to the No. 2 reactor mol / L cupric chloride solution, continue to stir for 5 minutes after mixing uniformly, stop stirring, and maintain this state for 12 hours to obtain a dynamic polymer plasticizer swollen gel. Performance test: 90% compressive strength (MPa): 1.35±0.22; tensile strength (MPa): 2.14±0.37; elongation at break (%): 245.15±23.44. Under the action of tensile force, the synergistic effect between hydrogen bond and metal-ligand interaction improves the tensile strength and elongation at break of the dynamic pol...

Embodiment 2

[0199] Add 40g of 3-isocyanato-1-propene into the dry No. 1 reactor, add 0.5g of potassium persulfate (KPS) while stirring, increase the temperature to 80°C, stir and react for 4h, maintain this temperature while adding 40g while stirring The 5-(aminomethyl)-2-(1-pyrazolyl)pyridine, after continuing the reaction for 2h, add 11g of 1,4-diaminobutane, and after continuing the reaction for 1h, transfer the reactant to the wide-mouthed In the No. 2 reactor, add 100 mL 1-butyl-3-methylimidazole hexafluorophosphate ionic liquid, 2 mL 0.2mol / L nickel chloride solution, and 1 g graphene to the No. 2 reactor, and continue to stir for 5 min. After sonicating for 20 minutes and mixing uniformly, stop stirring. After maintaining this state for 12 hours, a dynamic polymer ionic liquid swollen gel is obtained. After pressing the surface of the sample with a finger, the sample can show good elasticity and can be stretched in a larger range. Make it into a dumbbell-shaped spline with a size o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com