Method for producing, collecting and purifying potassium permanganate through liquid-phase electrolytic method

A technology of potassium permanganate and electrolysis, applied in electrolysis process, electrolysis components, etc., can solve the problems of low efficiency and unsatisfactory purity of potassium permanganate, and achieve the effect of convenient precipitation, convenient filtering of impurities, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

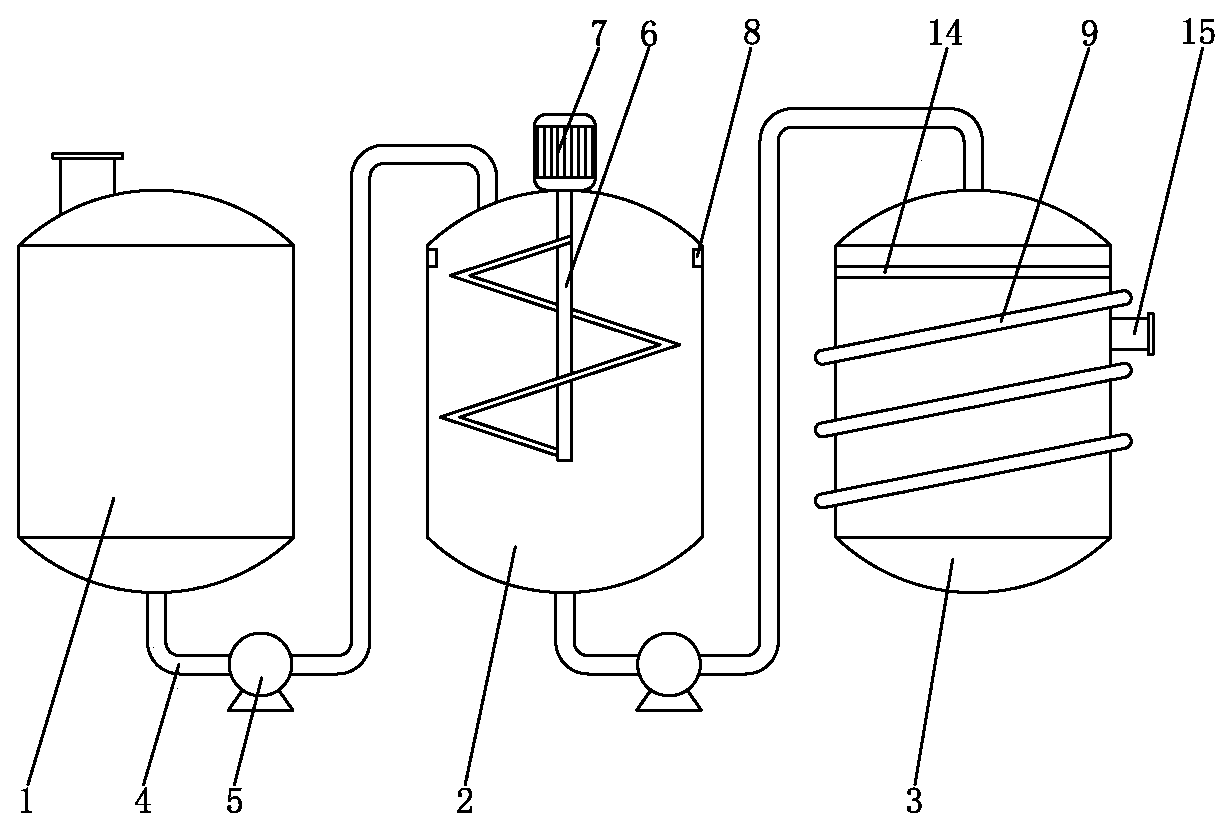

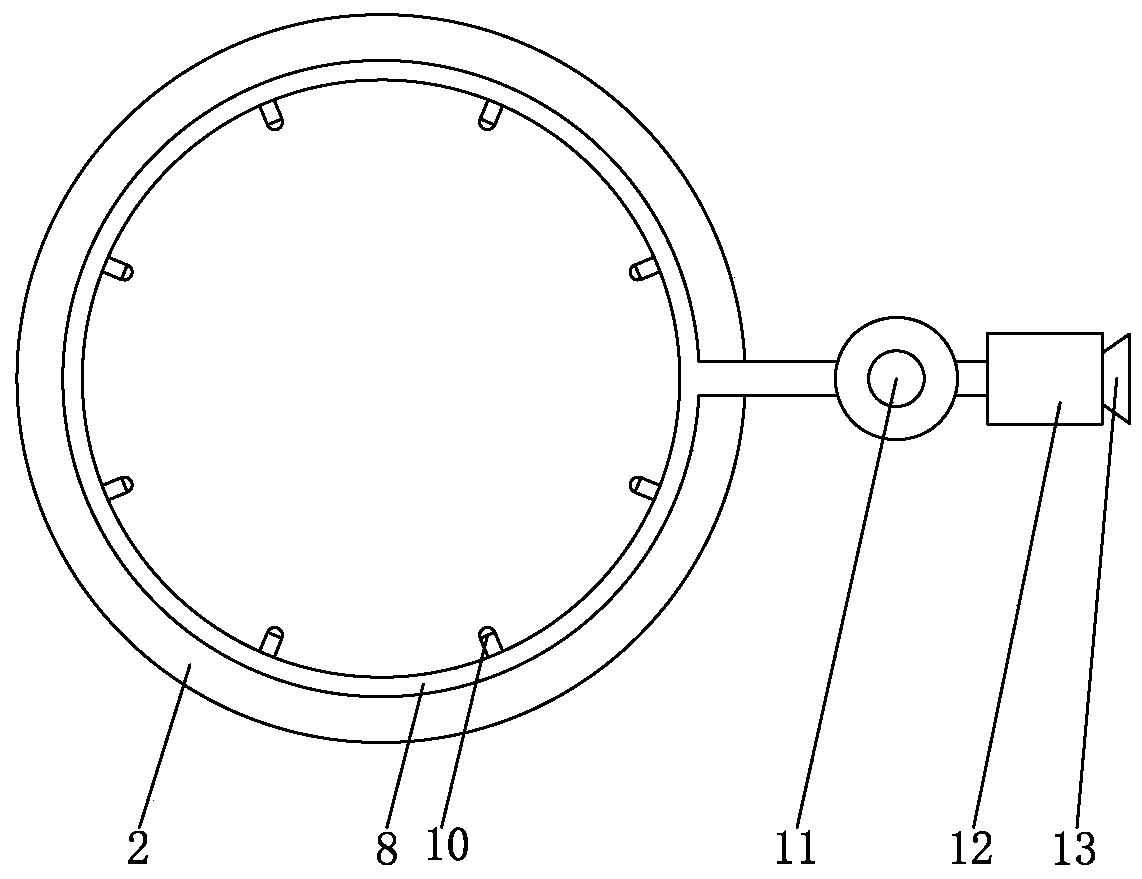

Method used

Image

Examples

Embodiment 1

[0044] Step S1: Take 340g of potassium manganate crystals by electronic scales, put the 340g of potassium manganate crystals into the electrolytic cell, add water and potassium hydroxide solution to prepare an electrolyte, wherein the potassium manganate is set to 180g / L, and the hydroxide Potassium is set to 60g / L;

[0045] Step S2: Heating the electrolytic cell so that the temperature of the electrolyte is always kept at about 70°C, and then electrifying for ionization, potassium manganate is oxidized to potassium permanganate at the anode, and crystallizes out;

[0046] Step S3: After the electrolyte solution is cooled, the crude product of potassium permanganate is obtained by centrifugal separation in a centrifuge;

[0047] Step S4: using the solubility difference of potassium permanganate at different temperatures, the crude product of potassium permanganate is purified by recrystallization, and the specific purification steps are as follows:

[0048] Step S41: Take out a...

Embodiment 2

[0054] Step S1: Take 440g of potassium manganate crystals by electronic scales, put the 440g of potassium manganate crystals into the electrolytic cell and add water and potassium hydroxide solution to prepare an electrolyte solution, wherein the potassium manganate is set to 220g / L, and the hydroxide Potassium is set to 65g / L;

[0055] Step S2: Heating the electrolytic cell so that the temperature of the electrolyte is always kept at about 70°C, and then electrifying for ionization, potassium manganate is oxidized to potassium permanganate at the anode, and crystallizes out;

[0056] Step S3: After cooling the electrolyte solution, the crude product of potassium permanganate is obtained by centrifugal separation in a centrifuge;

[0057] Step S4: using the solubility difference of potassium permanganate at different temperatures, the crude product of potassium permanganate is purified by recrystallization, and the specific purification steps are as follows:

[0058] Step S41...

Embodiment 3

[0064] Step S1: Take 540g of potassium manganate crystals by electronic scales, put the 540g of potassium manganate crystals into the electrolytic cell, add water and potassium hydroxide solution to prepare an electrolyte, wherein the potassium manganate is set to 260g / L, and the hydroxide Potassium is set to 70g / L;

[0065] Step S2: Heating the electrolytic cell so that the temperature of the electrolyte is always kept at about 70°C, and then electrifying for ionization, potassium manganate is oxidized to potassium permanganate at the anode, and crystallizes out;

[0066] Step S3: After cooling the electrolyte solution, the crude product of potassium permanganate is obtained by centrifugal separation in a centrifuge;

[0067] Step S4: using the solubility difference of potassium permanganate at different temperatures, the crude product of potassium permanganate is purified by recrystallization, and the specific purification steps are as follows:

[0068] Step S41: Take out a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com