Preparation method of charcoal-loaded zero-valent iron catalytic material

A technology of catalytic materials and zero-valent iron, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as high cost, secondary pollution, weak slow-release ability, etc., and achieve good removal and reducing effect, reducing process cost, reducing the effect of preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The Fe content is 25%, and the preparation steps of biochar-loaded zero-valent iron catalytic material BC / nZVI are as follows:

[0022] (1) Take 1.8 g of oak chips crushed to below 100 mesh and add them to the polytetrafluoroethylene bottle of the autoclave, and then add 18 mL of deionized water. Under the condition of 200 ° C for 20 minutes, the hydrothermal charcoal HC was obtained by filtration and drying.

[0023] (2) Add HC to 100 mL of Fe(NO 3 ) 3 solution, stirred for 12h, filtered and dried.

[0024] (3) Load the supported HC obtained in (2) into a porcelain boat, put the porcelain boat into a tube furnace, and carbonize at 800°C for 40 minutes in a nitrogen atmosphere.

[0025] (4) After cooling the dried sample in (3), grind and sieve to obtain the biochar-loaded zero-valent iron catalytic material BC / nZVI.

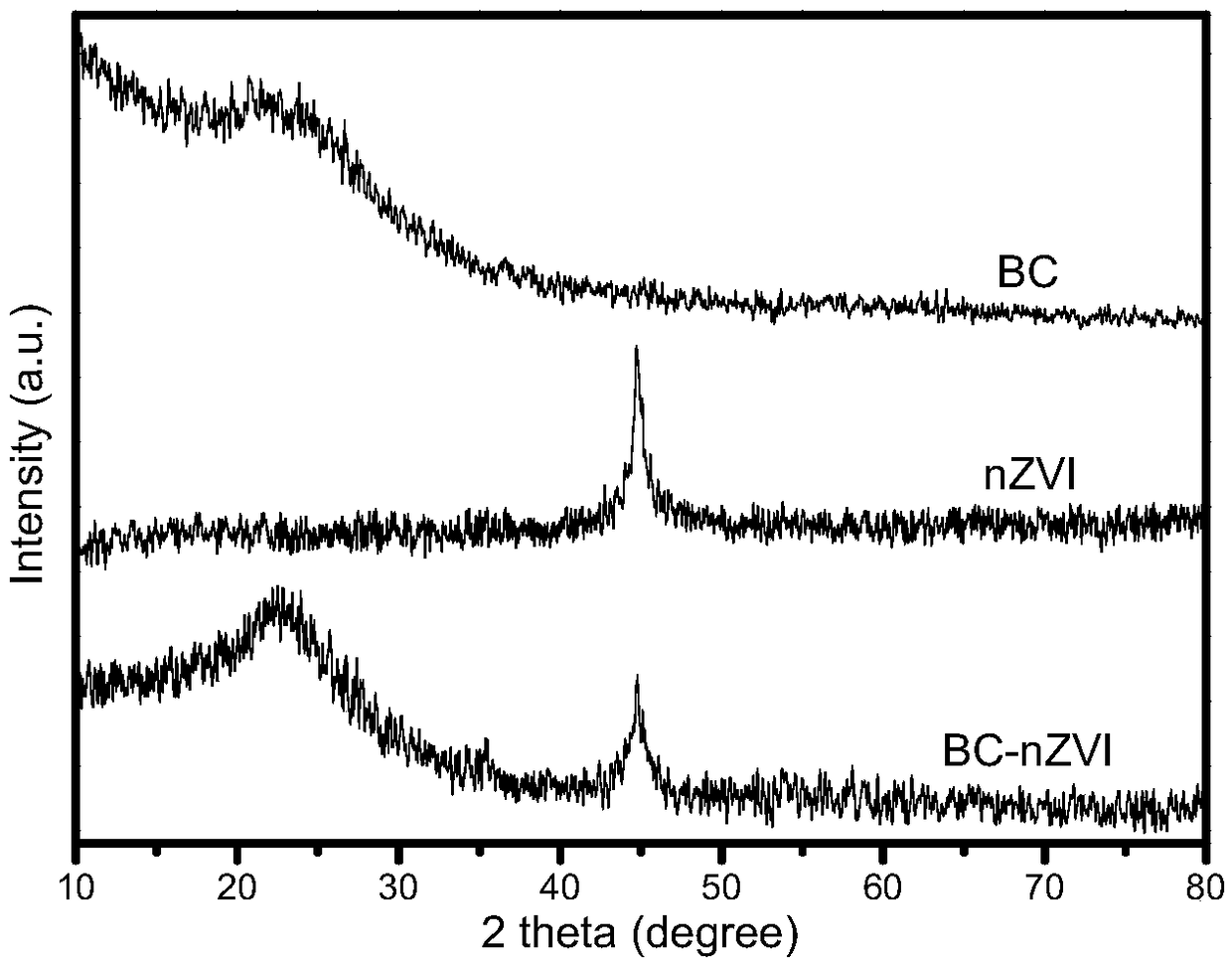

[0026] figure 1 XRD patterns of biochar BC, nanometer zero-valent iron nZVI, and biochar-supported zero-valent iron catalytic material BC / nZVI. Dep...

Embodiment 2

[0028] The Fe content is 20%, and the preparation steps of biochar-loaded zero-valent iron catalytic material BC / nZVI are as follows:

[0029] (1) Take 1.8 g of oak chips crushed to below 100 mesh and add them to the polytetrafluoroethylene bottle of the autoclave, and then add 18 mL of deionized water. Under the condition of 200 ° C for 20 minutes, the hydrothermal charcoal HC was obtained by filtration and drying.

[0030] (2) Add HC to 100 mL of Fe(NO 3 ) 3 solution, stirred for 12h, filtered and dried.

[0031] (3) Load the supported HC obtained in (2) into a porcelain boat, put the porcelain boat into a tube furnace, and carbonize at 800°C for 40 minutes in a nitrogen atmosphere.

[0032] (4) After the sample dried in step (3) is cooled, it is ground and sieved to obtain the biochar-loaded zero-valent iron catalytic material BC / nZVI.

Embodiment 3

[0034] The Fe content is 30%, and the preparation steps of biochar-loaded zero-valent iron catalytic material BC / nZVI are as follows:

[0035] (1) Take 1.8 g of oak chips crushed to below 100 mesh and add them to the polytetrafluoroethylene bottle of the autoclave, and then add 18 mL of deionized water. Under the condition of 200 ° C for 20 minutes, the hydrothermal charcoal HC was obtained by filtration and drying.

[0036] (2) Add HC to 100 mL of Fe(NO 3 ) 3 solution, stirred for 12h, filtered and dried.

[0037] (3) Load the supported HC obtained in (2) into a porcelain boat, put the porcelain boat into a tube furnace, and carbonize at 800°C for 40 minutes in a nitrogen atmosphere.

[0038] (4) After the sample dried in step (3) is cooled, it is ground and sieved to obtain the biochar-loaded zero-valent iron catalytic material BC / nZVI.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com