Synergistic flame retardant containing cardanol-based nitrogen and phosphorus, its preparation method and application

A synergistic flame-retardant, cardanol-based technology, which is applied in the field of polymer materials, can solve the problems of reduced flame retardancy of phenolic foam materials, achieve good flame retardancy, excellent mechanical properties, and save resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

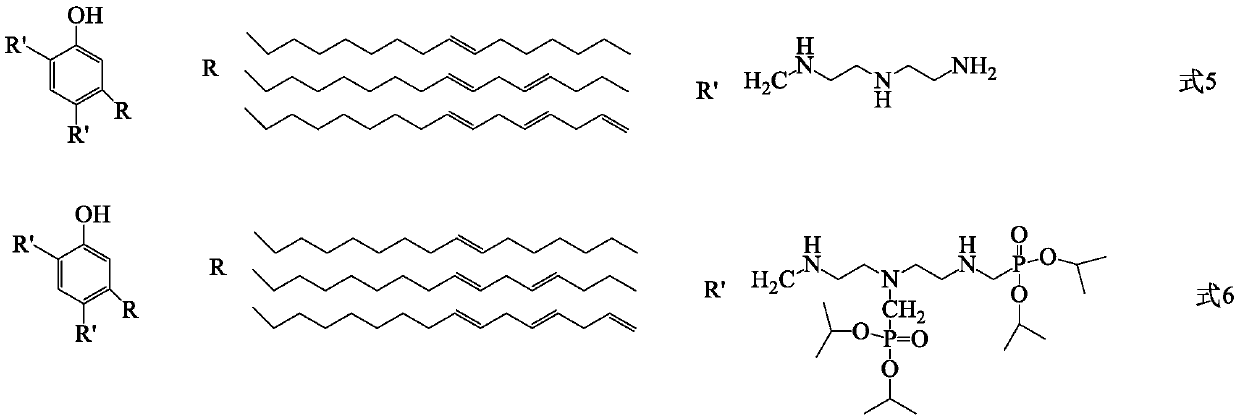

[0020] The invention provides a method for preparing the phenolic resin containing cardanol-based nitrogen-phosphorus synergistic flame retardant and the foam with simple preparation process, low cost and environmental protection. A method for preparing a phenolic resin containing cardanol-based nitrogen-phosphorus synergistic flame retardant and a foam. Cardanol is reacted with measured amine compounds and formaldehyde under a basic catalyst for a period of time at a certain temperature, and then washed with water, liquid separated, and vacuum distilled to remove small molecular substances to obtain nitrogen-containing cardanol. The substance is uniformly mixed with the phosphorus-containing compound, formaldehyde (same as above) and an organic solvent, and reacted at 25-120 DEG C for 0.5-24 hours to obtain the cardanol-based nitrogen-phosphorus synergistic flame retardant. The substance is evenly blended with curing agent, foaming agent, surfactant and other additives, poure...

Embodiment 1

[0032] Preparation of cardanol-based nitrogen and phosphorus synergistic flame retardant

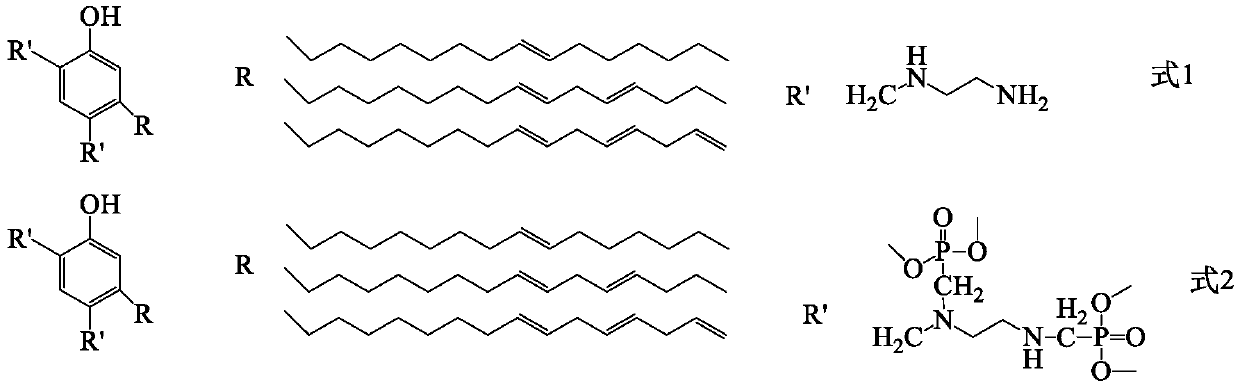

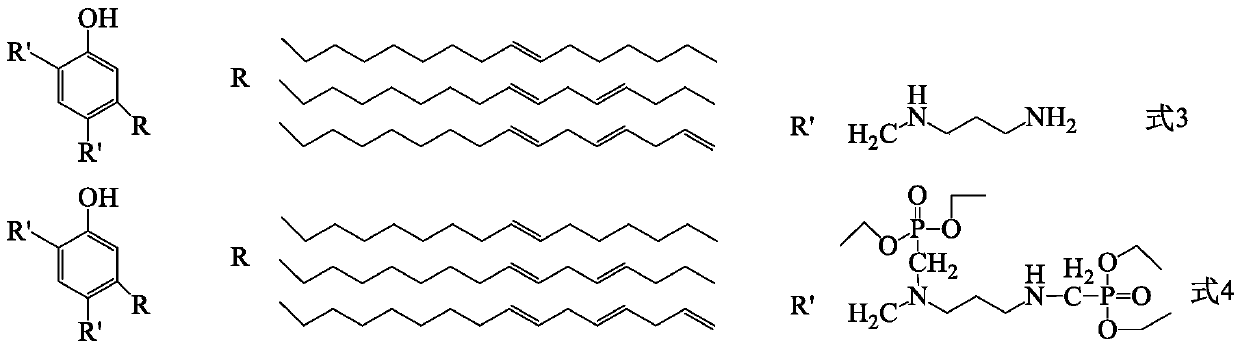

[0033] Add a certain amount of cardanol, ethylenediamine, paraformaldehyde and NaOH (5% of cardanol quality) into the reactor, and the molar ratio of each component is n 腰果酚 :n 乙二胺 :n 甲醛 =1:3:3, the reaction temperature is 60°C, the reaction time is 3h, and then the small molecular substances are removed by water washing, liquid separation, and vacuum distillation to obtain the nitrogen-containing cardanol shown in the following formula 1. Add 100g of nitrogen-containing cardanol, 31.2g of paraformaldehyde and 114.4g of dimethyl phosphite obtained above into the reactor, react at a temperature of 80°C for 2h, wash with water and distill under reduced pressure to obtain the cashew nut shown in the following formula 2 Phenolic nitrogen and phosphorus synergistic flame retardants. According to the proton nuclear magnetic resonance spectrum of this nitrogen-containing cardanol, in 1H NMR ...

Embodiment 2

[0038] Preparation of cardanol-based nitrogen and phosphorus synergistic flame retardant

[0039] Add a certain amount of cardanol, propylenediamine, paraformaldehyde and KOH (3% of cardanol quality) into the reactor, and the molar ratio of each component is n 腰果酚 :n 丙二胺:n 甲醛 =1:3:3, the reaction temperature is 90°C, the reaction time is 2h, and then the small molecular substances are removed by water washing, liquid separation, and vacuum distillation to obtain the nitrogen-containing cardanol shown in the following formula 3. Add 100 g of the nitrogen-containing cardanol obtained above, 29 g of paraformaldehyde and 133.8 g of diethyl phosphite into the reactor, react at a temperature of 90° C. for 2 hours, wash with water and distill under reduced pressure to obtain the cardanol shown in the following formula 4 Nitrogen and phosphorus synergistic flame retardants. According to the hydrogen nuclear magnetic resonance spectrum of this nitrogen-containing cardanol, it can be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com