Preparation method of modified graphene/acrylate composite water-based coating

An acrylate and water-based coating technology, applied in the coating and other directions, can solve the problems of poor dispersion, easy stacking and agglomeration, and achieve the effects of improving mechanical properties, improving dispersion uniformity, and reducing agglomeration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

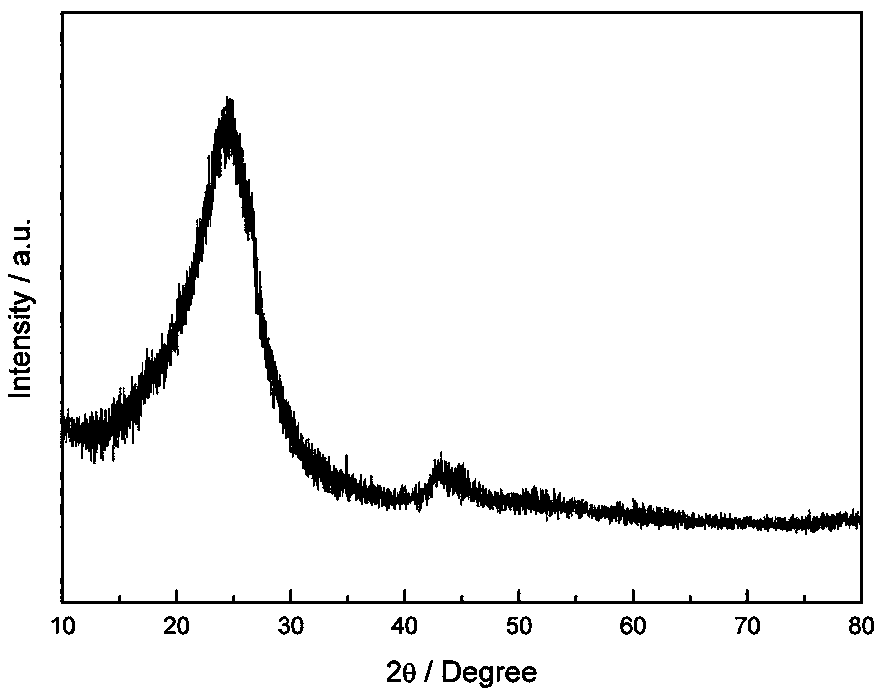

[0027] 1. Use acidified intercalation and ultrasonic treatment of expanded graphite to obtain few-layer graphene (1~5 layers): add 1g of expanded graphite to ethanol / water mixture (13:7, v / v, 400mL), at room temperature Stirred under 24 h, then sonicated (KQ-500DB, 500W) for another 20 h, the sample was collected by filtration, then dried in a vacuum oven, a part of this sample (500 mg) was added to the pre-cooled in ice bath Nitric acid / sulfuric acid (1:3, v / v, 80 mL), after sonication for 3 days, the mixture was transferred to water (1 L), and the treated graphite was collected by filtration and washed repeatedly with deionized water until neutral pH, and dried in a vacuum oven;

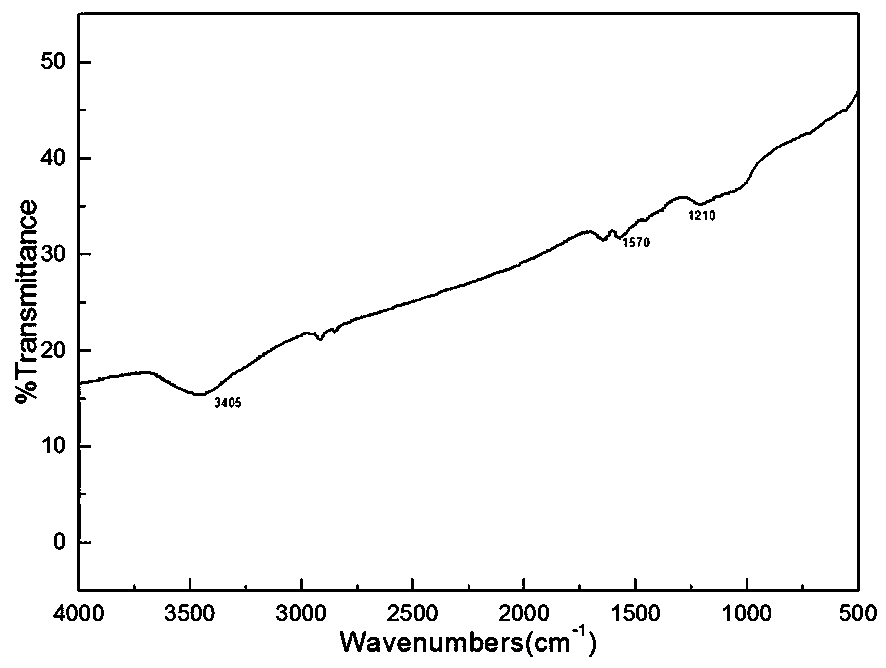

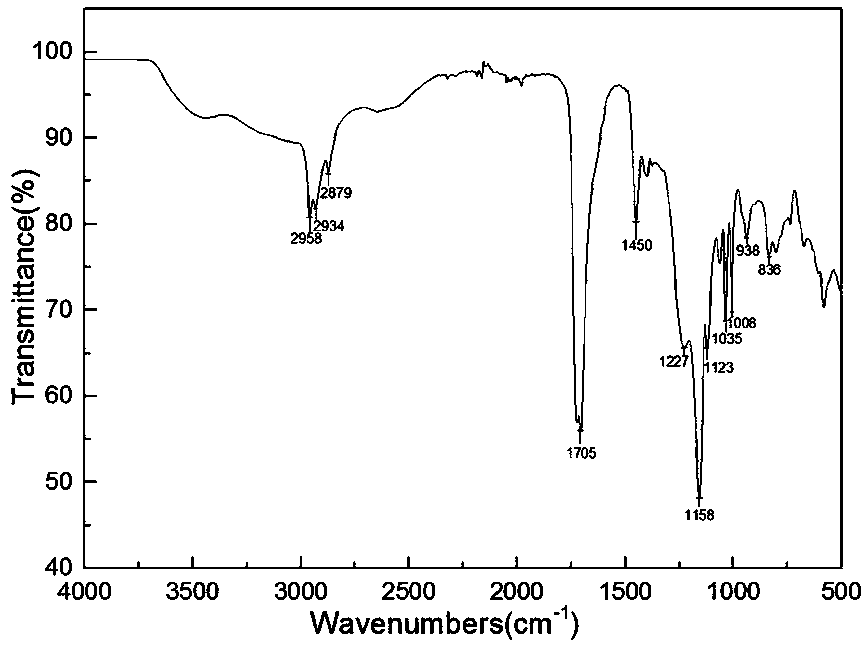

[0028] 2. Preparation of cetyltrimethylammonium bromide intercalated graphene: add 1.8g of cetyltrimethylammonium bromide powder into 58mL deionized water and stir to dissolve; After the graphene is ground and refined, it is added to the cetyltrimethylammonium bromide solution prepared above, and ...

Embodiment 2

[0032] 1. Use acidified intercalation and ultrasonic treatment of expanded graphite to obtain few-layer graphene (1~5 layers): add 1g of expanded graphite to ethanol / water mixture (13:7, v / v, 400mL), at room temperature Stirred under 24 h, then sonicated (KQ-500DB, 500W) for another 20 h, the sample was collected by filtration, then dried in a vacuum oven, a part of this sample (500 mg) was added to the pre-cooled in ice bath Nitric acid / sulfuric acid (1:3, v / v, 80 mL), after sonication for 3 days, the mixture was transferred to water (1 L), and the treated graphite was collected by filtration and washed repeatedly with deionized water until neutral pH, and dried in a vacuum oven;

[0033] 2. Preparation of graphene intercalated with cetyltrimethylammonium bromide: add 3g of cetyltrimethylammonium bromide powder into 58mL deionized water and stir to dissolve; add 0.3g of few-layer graphite Grinding and refining treatment, add it to the cetyltrimethylammonium bromide solution ...

Embodiment 3

[0036] 1. Use acidified intercalation and ultrasonic treatment of expanded graphite to obtain few-layer graphene (1~5 layers): add 1g of expanded graphite to ethanol / water mixture (13:7, v / v, 400mL), at room temperature Stirred under 24 h, then sonicated (KQ-500DB, 500W) for another 20 h, the sample was collected by filtration, then dried in a vacuum oven, a part of this sample (500 mg) was added to the pre-cooled in ice bath Nitric acid / sulfuric acid (1:3, v / v, 80 mL), after sonication for 3 days, the mixture was transferred to water (1 L), and the treated graphite was collected by filtration and washed repeatedly with deionized water until neutral pH, and dried in a vacuum oven;

[0037] 2. Preparation of cetyltrimethylammonium bromide intercalated graphene: add 4.2g of cetyltrimethylammonium bromide powder into 58mL deionized water and stir to dissolve; After the graphene is ground and refined, it is added to the cetyltrimethylammonium bromide solution prepared above, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com