A kind of comprehensive recovery processing method of cobalt sulfur concentrate

A cobalt-sulfur concentrate and recovery treatment technology, applied in the direction of instrumentation, optics, process efficiency improvement, etc., can solve the problems of low bioleaching treatment capacity, high iron leaching rate, low recovery rate, etc., achieve low treatment cost, improve Effect of high cobalt content and direct copper recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

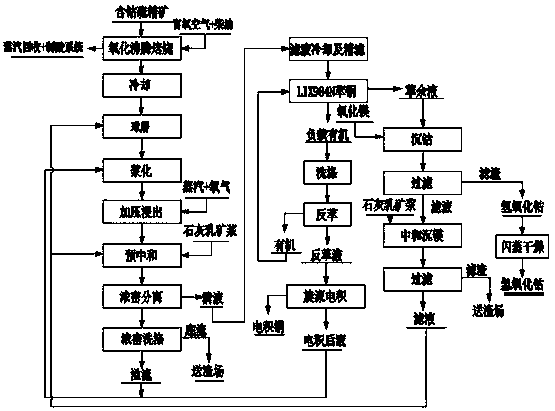

[0033]Embodiment 1: a kind of cobalt-sulfur concentrate comprehensive recovery processing method of the present invention, its technological process is as follows figure 1 shown, including the following steps:

[0034] 1) The cobalt-sulfur concentrate is roasted in a fluidized roaster, using diesel oil as fuel, and blowing oxygen-enriched air to support the combustion. The temperature in the roaster is controlled at 800-950°C to obtain calcined sand and SO 2 Flue gas, SO 2 The waste heat of the flue gas is used to produce steam in the boiler, and then purified to make acid. The roasted calcine is cooled to 250°C and ground by a wet ball mill. More than 94% of the fine material after grinding has a particle size of less than 150 mesh. The obtained fine material and 200g / L dilute sulfuric acid solution are mixed and slurried at a mass ratio of 4:1 and stirred, and saturated steam is passed through for pre-leaching until the temperature of the reaction solution rises to 80°C and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com