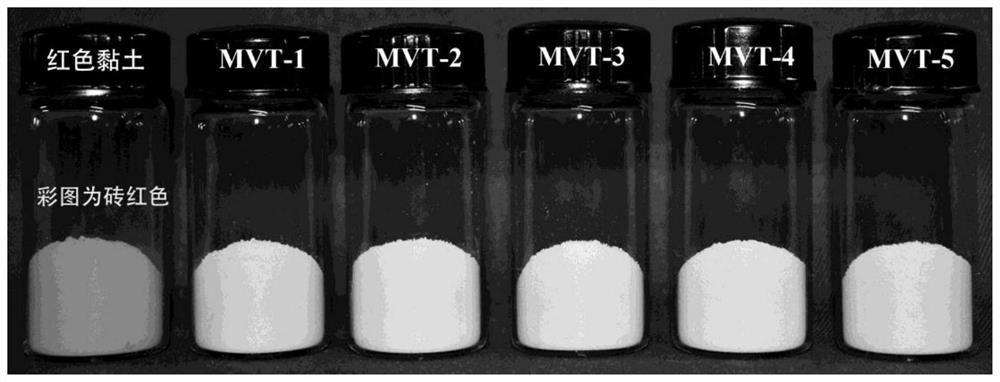

A method for synthesizing white potassium mica using red mixed clay minerals

A technology of clay minerals and potassium mica, which is applied in silicon compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of no research reports and no precedents for industrial applications, etc., and achieve the expansion of application fields, good batch stability, The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

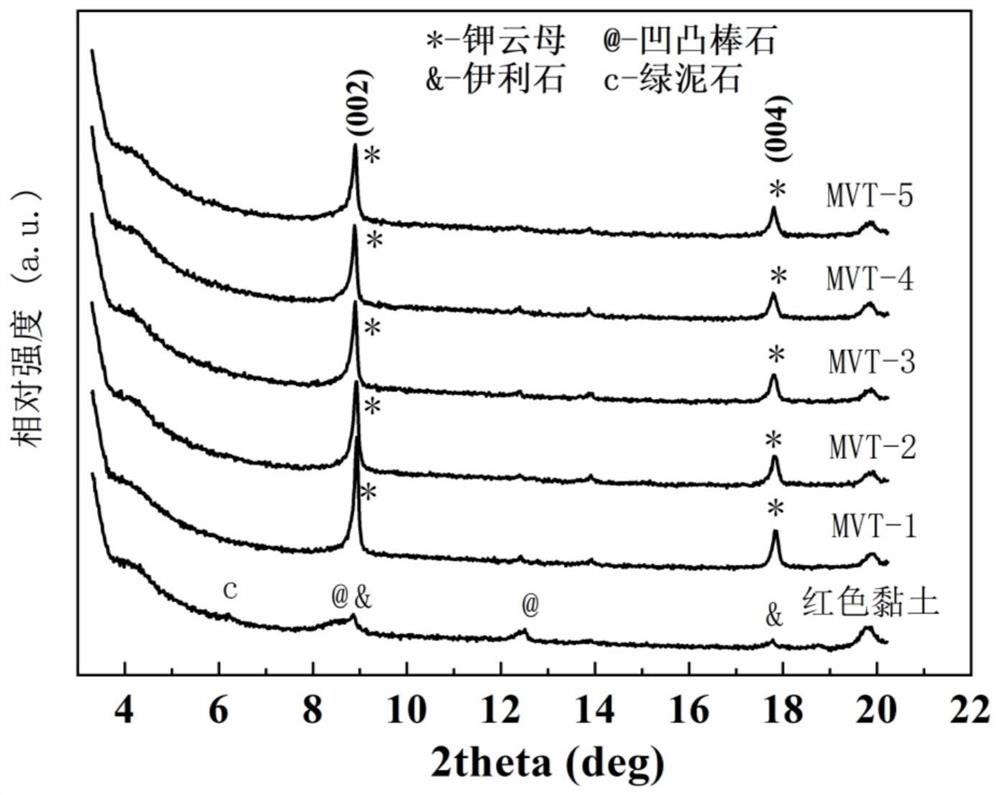

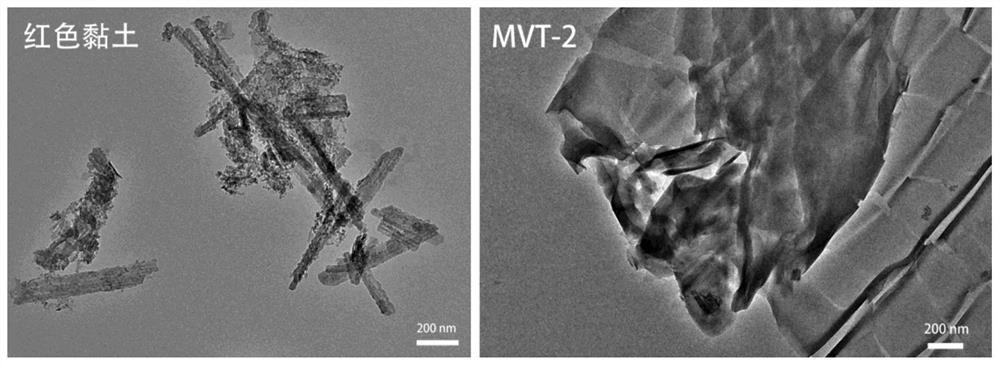

[0034] 100kg of red mixed clay minerals (containing attapulgite 37.3%, illite 9.6%, chlorite 12.1%, montane mixed clay 6.2%, calcite content 7.9%, dolomite 2.8%, hematite 4.9%) pulverized After passing through a 200-mesh sieve, 25 kg of an aqueous solution containing 5% (mass fraction) hydrogen peroxide and 2.5% (mass fraction) nitric acid was sprayed into it, and the mixture was stirred and mixed well. Then, the wetted ore powder was subjected to three-roll extrusion grinding for 2 times, and then air plasma ball milling (discharge voltage: 12kV; discharge power: 2.5KW, rotating speed: 950rpm) for 30min to obtain an activated solid-state precursor. The solid-state precursor was dispersed in an aqueous solution of 1.80 mol / L sulfamic acid at a solid-liquid ratio of 1:9, and then 25 g of glutamic acid was added as an auxiliary agent. After 10 minutes of ultrasonication, mechanical stirring was performed to make it fully mixed. The hydrothermal reaction was carried out for 11.5h...

Embodiment 2

[0036] 100kg of red mixed clay minerals (containing attapulgite 35.2%, illite 14.5%, chlorite 7.6%, montane mixed clay 3.1%, calcite 18.2%, dolomite 1.5%, hematite 3.2%) were crushed for 200 After mesh sieving, 53.85 kg of an aqueous solution containing 5% (mass fraction) hydrogen peroxide and 2.5% (mass fraction) nitric acid was sprayed into it, and the mixture was stirred and mixed well. Then, the wetted mineral powder was subjected to three-roll extrusion grinding treatment twice, and then air plasma ball milling (discharge voltage was 8kV, discharge power was 1.0KW, and rotational speed was 1450rpm) for 60min to obtain an activated solid precursor. The solid-state precursor was dispersed in a 0.20mol / L ethylenediaminetetraacetic acid aqueous solution according to a solid-liquid ratio of 1:9, and then 100g of glutamic acid was added as a reaction aid. After 10 minutes of ultrasonication, mechanical stirring was performed to make it fully mixed. , and then hydrothermally rea...

Embodiment 3

[0038] 100kg of red mixed clay minerals (containing attapulgite 23.2%, illite 14.5%, chlorite 12.0%, smectite 6.1%, calcite 16.1%, dolomite 2.6%, hematite 4.7%) were crushed for 200 After mesh sieving, spray 35 kg of an aqueous solution containing 5% (mass fraction) hydrogen peroxide and 2.5% (mass fraction) nitric acid, and then mix well. Then, the wetted powder was subjected to three-roll extrusion grinding treatment twice, and then air plasma ball milling (discharge voltage of 10kV, discharge power of 2KW, and rotational speed of 1200rpm) was carried out for 40min to obtain an activated solid precursor. The solid-state precursor was dispersed in a mixed acid aqueous solution containing 0.8mol / L oxalic acid and 0.8mol / L ethylenediaminetetraacetic acid according to a solid-liquid ratio of 1:9, and then 50g of the auxiliary glutamic acid was added, and ultrasonicated for 10 After 10 minutes, mechanical stirring was performed to make it fully mixed, and then hydrothermal reacti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com