A preparation method of a polar lithium sulfide battery cathode sulfur-carrying material and a prepared lithium sulfide battery cathode sulfur-carrying material

A lithium-sulfur battery and cathode technology, which is applied in the field of cathode sulfur-carrying materials for polar lithium-sulfur batteries, can solve the problems of increasing chemical adsorption capacity, decreasing battery coulombic efficiency, unfavorable electron transport, etc., and improving battery charge-discharge efficiency and cycle life. , Improve the charge and discharge efficiency and cycle life, the effect of simple nitrogen doping process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

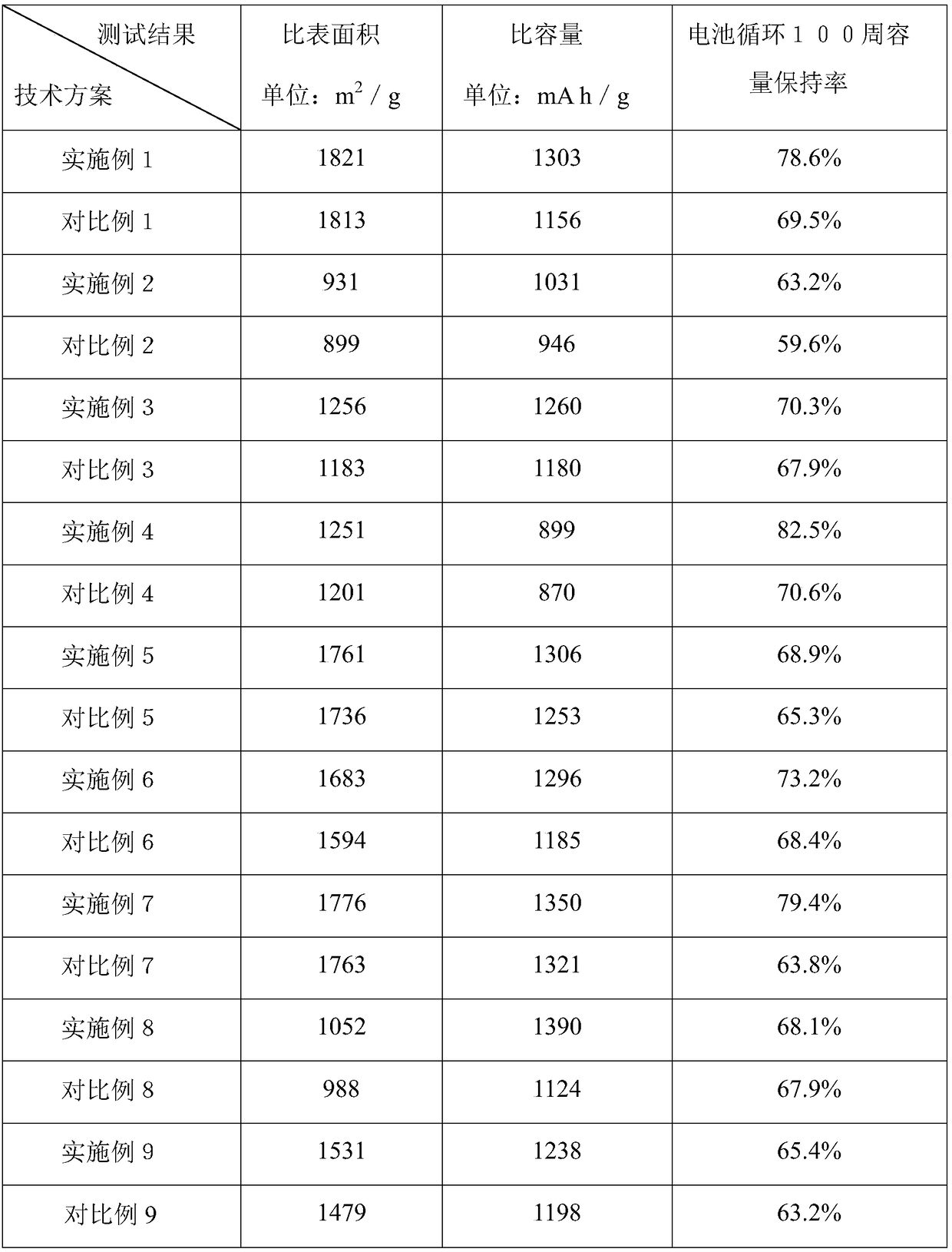

Examples

Embodiment 1

[0032] A method for preparing a positive electrode sulfur-carrying material for a polar lithium-sulfur battery, the steps are as follows:

[0033] Step 1: Heat and stir the metal elemental sodium and the N-methylpyrrolidone dispersion of carbon nanotubes with a solid content of 5% in a mass ratio of 1:3 in an oil bath at 160°C for 2 hours, then dry at 240°C for 4 hours Obtain solid A;

[0034] Step 2: the resulting solid A is placed in a tube furnace, N 2 Calcination at 800°C for 2-4 hours under atmosphere to obtain carbonized product B;

[0035]Step 3: Washing the carbonized product B with 2mol / L dilute hydrochloric acid, and then washing with deionized water;

[0036] Step 4: drying the washed product in a vacuum drying oven at 80° C. for 24 hours to obtain a nitrogen-doped porous carbon nanotube composite C with a high specific surface area;

[0037] Step 5: After mixing the above-mentioned compound C and sulfur powder at a mass ratio of 1:3, first keep warm at 155°C for...

Embodiment 2

[0042] A method for preparing a positive electrode sulfur-carrying material for a polar lithium-sulfur battery, the steps are as follows:

[0043] Step 1: Heat and stir the metal elemental sodium and the N-methylpyrrolidone dispersion of carbon nanotubes with a solid content of 5% in a mass ratio of 1:5 in an oil bath at 160°C for 2 hours, then dry at 240°C for 4 hours Obtain solid A;

[0044] Step 2: the resulting solid A is placed in a tube furnace, N 2 Calcination at 500°C for 2-4 hours under atmosphere to obtain carbonized product B;

[0045] Step 3: Wash the carbonized product B with 0.5mol / L dilute hydrochloric acid, and then with deionized water;

[0046] Step 4: drying the washed product in a vacuum drying oven at 80° C. for 24 hours to obtain a nitrogen-doped porous carbon nanotube composite C with a high specific surface area;

[0047] Step 5: After mixing the above-mentioned compound C and sulfur powder at a mass ratio of 1:3, first keep warm at 155°C for 10h, th...

Embodiment 3

[0051] A method for preparing a positive electrode sulfur-carrying material for a polar lithium-sulfur battery, the steps are as follows:

[0052] Step 1: Heat and stir the metal elemental lithium and the N-methylpyrrolidone dispersion of carbon nanotubes with a solid content of 5% in a mass ratio of 1:4 in an oil bath at 180°C for 2 hours, then dry at 240°C for 4 hours Obtain solid A;

[0053] Step 2: Place the obtained solid A in a tube furnace, and calcinate at 800°C for 2-4 hours under N2 atmosphere to obtain carbonized product B;

[0054] Step 3: Washing the carbonized product B with 1mol / L dilute hydrochloric acid, and then washing with deionized water;

[0055] Step 4: drying the washed product in a vacuum drying oven at 80° C. for 24 hours to obtain a nitrogen-doped porous carbon nanotube composite C with a high specific surface area;

[0056] Step 5: After mixing the above-mentioned compound C and sulfur powder at a mass ratio of 1:3, first keep warm at 155°C for 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com