Oxygen vacancy-contained VOCs eliminating catalyst and preparation method thereof

An oxygen deficiency, catalyst technology, applied in catalyst activation/preparation, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as poor activity and low light-off temperature, and achieve improved combustion. The effect of activity, small particle size and abundant raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] (1) Weigh 2.125g Co(NO 3 ) 2 ·6H 2 O, 2.364g Ce(NO 3 ) 3 ·6H 2 O and 4.2g urea are added into the water of 225ml and stirred to dissolve evenly, then add 3% dilute nitric acid dropwise to adjust the pH to be 2.5;

[0052] (2) Measure 22.4ml Si(OC 2 h 5 ) 4 and 40ml CH 3 CH 2 Add OH into the beaker, stir, and sonicate for 20 minutes to form a uniform and stable solution;

[0053] (3) Add the solution prepared in step 2 dropwise to the solution obtained in step 1 under stirring, and then stir for 4 hours;

[0054] (4) Put the solution prepared in step 3 into an oil bath at 90°C and heat it at a speed of 100 rad / min, while preventing water loss;

[0055] (5) After heating for 40 hours, the pH rises to about 8, and the solution becomes a gel state;

[0056] (6) Rinse the obtained gel three times with ethanol and deionized water respectively, put it in an oven at 80°C and dry it for 10 hours, grind the obtained solid and sieve it with an 80-mesh sieve;

[0057] ...

Embodiment 2

[0063] Except that the reduction time in step (7) in Example 1 is set to 0.5h, other experimental steps are carried out using the method of Example 1 to obtain a supported catalyst CoO containing certain oxygen defects. x -CeO x / SiO 2 .

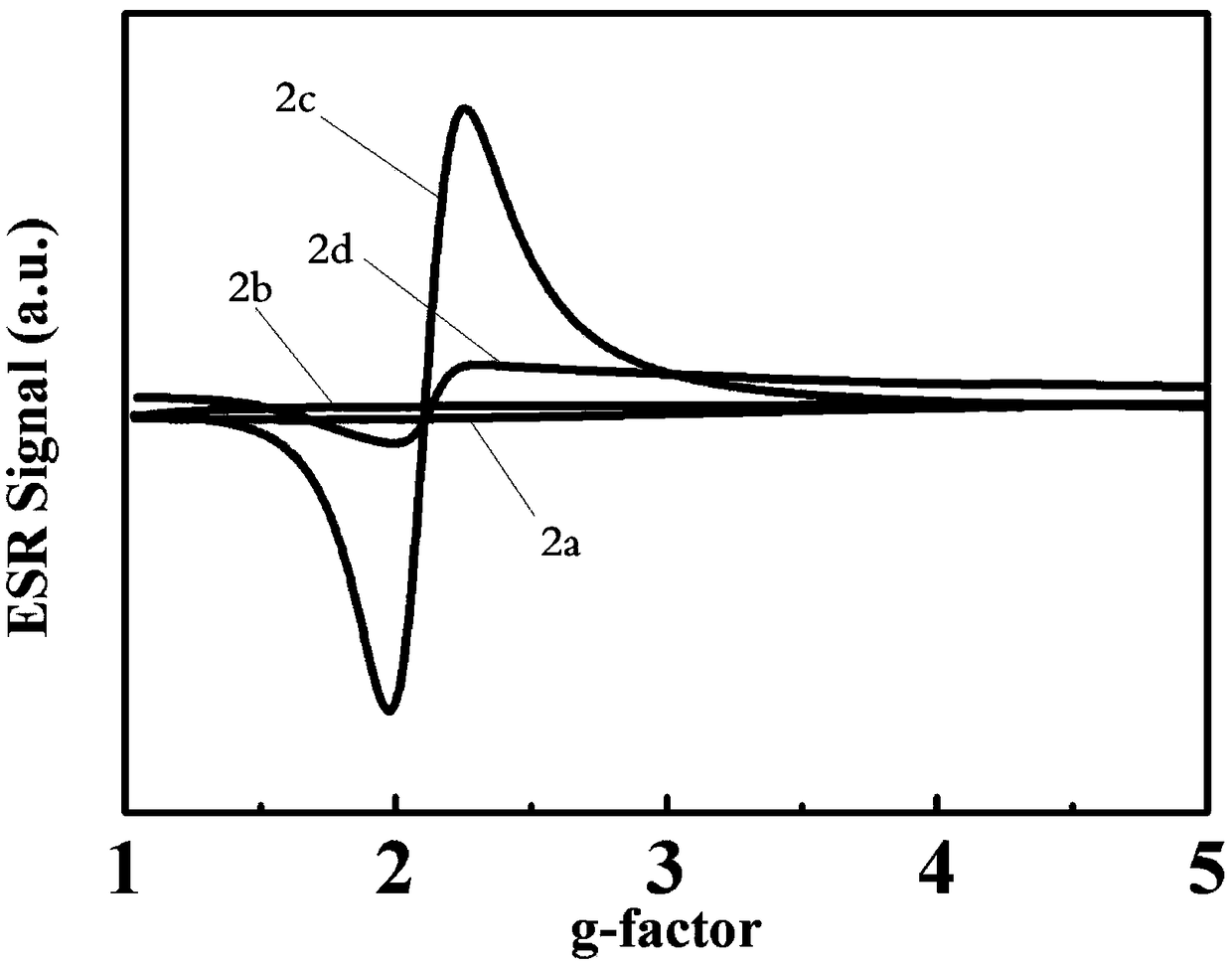

[0064] Test the concentration of oxygen vacancies in the catalyst by ESR (Electron Spin Resonance), see the test results figure 2 , figure 2 The ESR figure of the catalyst prepared for the embodiments of the present invention and comparative examples, figure 2 Among them, curve 2a is the ESR figure of the supported catalyst containing oxygen deficiency prepared in Comparative Example 1, curve 2b is the ESR figure of the supported catalyst containing oxygen deficiency prepared in Comparative Example 2, and curve 2c is the supported catalyst prepared in Example 1 The ESR figure of catalyst, curve 2d is the ESR figure of the supported catalyst prepared in embodiment 2; By figure 2 It can be seen that the catalyst prepared by the presen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com