A kind of ink composition with high heat resistance and high light transmittance and its application

A technology of ink composition and high light transmittance, which can be used in inks, applications, household appliances, etc., can solve the problems of low light transmittance, air permeability, heat resistance, etc., and achieve low water vapor transmission rate and low oxygen transmission rate , the effect of reducing shrinkage volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0074] The preparation of the inorganic barrier layer can deposit a layer of SiNx by PECVD, with a thickness ranging from 0.1 μm to 20 μm.

[0075] In addition, there are many options for physical property testing. For example, some implementation methods of cured films have Fourier Transform Infrared (FT-IR) real-time spectroscopy to measure the degree of curing or a weighing method to measure the degree of curing.

[0076] The organic thin film ink composition of the present application can be used for encapsulation of flexible OLED display devices. The flexible OLED device mainly comprises: an organic light-emitting diode, an inorganic layer for encapsulation, and an organic layer stacked together. The OLED device device includes a substrate ITO, a device (organic light-emitting diode) for the device formed on the substrate, and a package member formed on the package member and including an inorganic barrier layer SiN x , organic barrier layer, inorganic barrier layer SiN ...

Embodiment 1

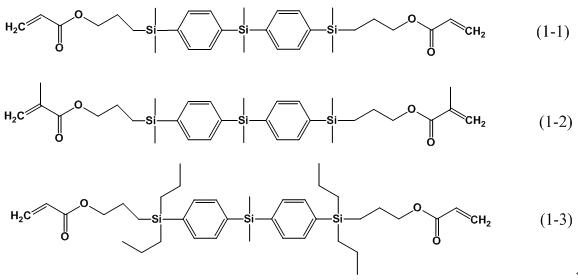

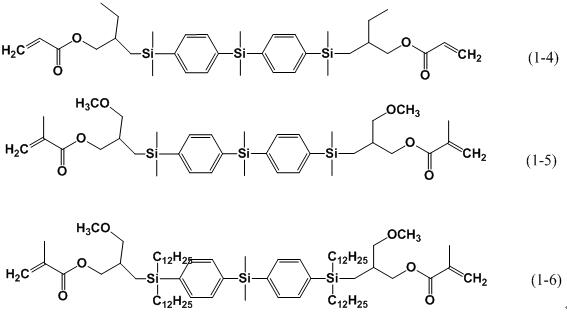

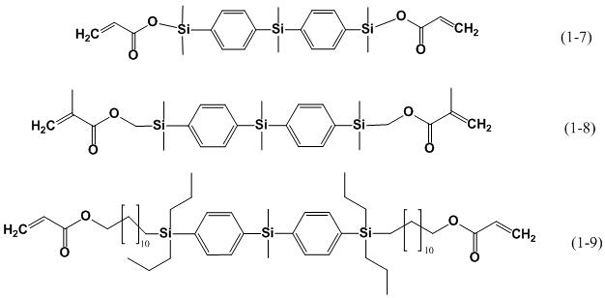

[0079] Embodiment 1: Preparation of silicon-containing monomer 1-1

[0080] Silicon-containing monomer 1-1 is prepared according to the following reaction formula:

[0081]

[0082] 1.1. Synthesis of TM-1

[0083] Add 4.8g (0.2mol) magnesium chips in a 250mL three-necked flask equipped with a constant pressure dropping funnel, an electric stirrer and a condenser, and use high-purity N 2 permutation three times, at N 2 Under protection, add 40mL of tetrahydrofuran to cover the magnesium chips, drop a small amount of mixed solution prepared by 47g (0.2moL) p-dibromobenzene and 100mL tetrahydrofuran at room temperature to initiate the reaction, and then slowly add the mixed solution to maintain the reaction under slight reflux , Dropped within 1h, and when there is no reflux, use an oil bath to heat and reflux for 1h. After cooling to room temperature, 11.6 g (0.09 moL) of dichlorodimethylsilane was added dropwise in a cold water bath at about 10°C. After the drop was compl...

Embodiment 2

[0091] Embodiment 2: Preparation of silicon-containing monomer 1-2

[0092] Silicon-containing monomer 1-2 is prepared according to the following reaction formula:

[0093]

[0094] Add 250ml ethyl acetate, 16g (0.05moL) bis(p-bromophenylsilyl) dimethyl silicon and 6g (0.1moL) Allyl alcohol, with high purity N 2 permutation three times, at N 2 Under protection, 4.8 g of palladium carbon (5% content) was added to maintain the reaction (80° C.) under a slight reflux state for 4 hours.

[0095] Ethyl acetate was evaporated to obtain 22g of crude product, 100mL of dichloromethane and 12mL of triethylamine were added, the reaction solution was cooled to 0°C, 20g (0.2mol) of 2-methacryloyl chloride was slowly added dropwise, and the reaction was kept at 0°C overnight. Residual solvent was removed by distillation and purified by column chromatography to obtain 20.88g of product with a yield of 72%, purity: 99.3%, M / e: 580.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com