Method for grinding zirconia ceramics

A zirconia ceramic and grinding method technology, which is applied in chemical instruments and methods, grinding devices, grinding machine tools, etc., can solve the problems of low yield and low efficiency of processed products, achieve high yield, reduce processing difficulty, and improve processing efficiency. effect of time reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

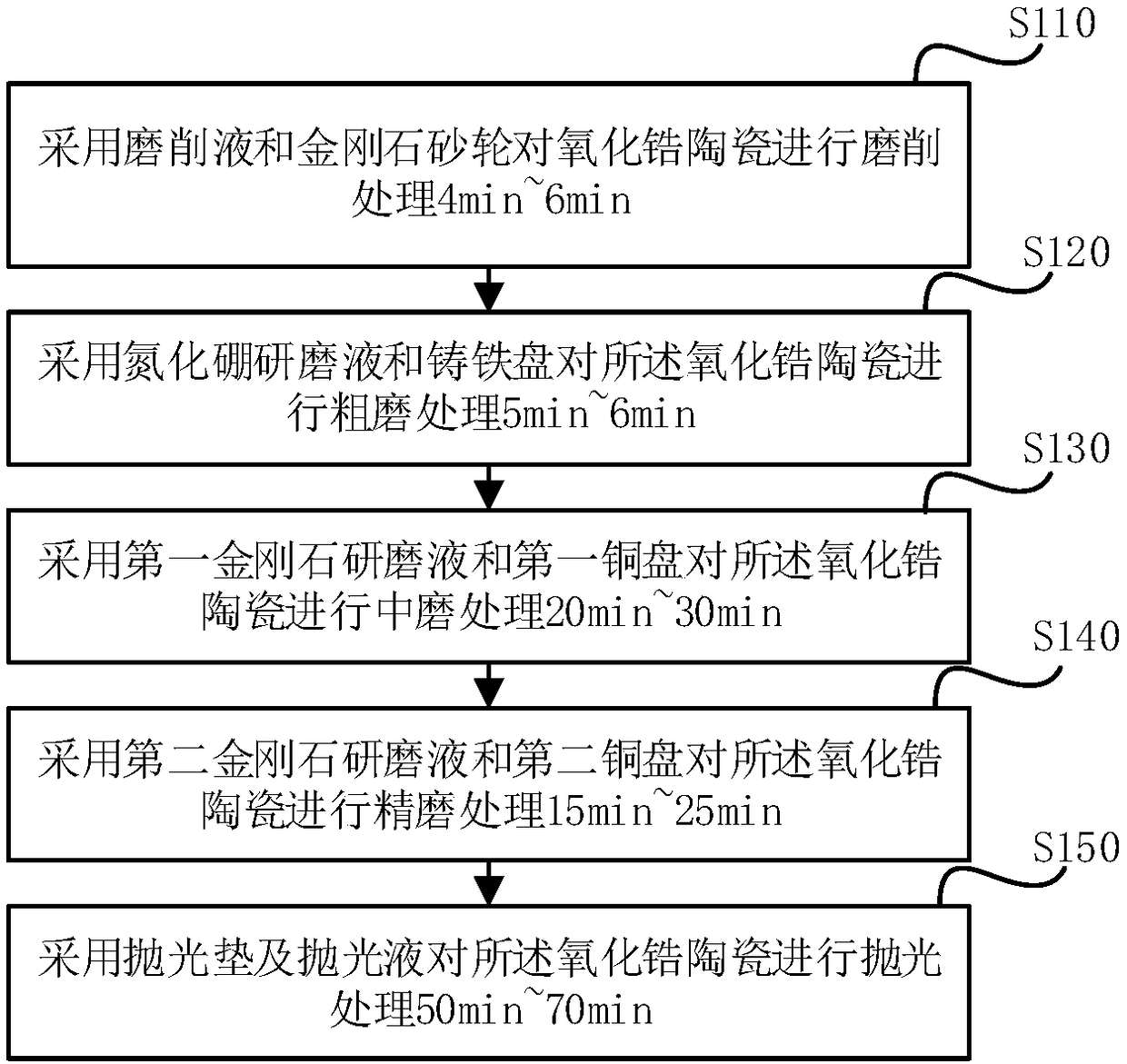

Method used

Image

Examples

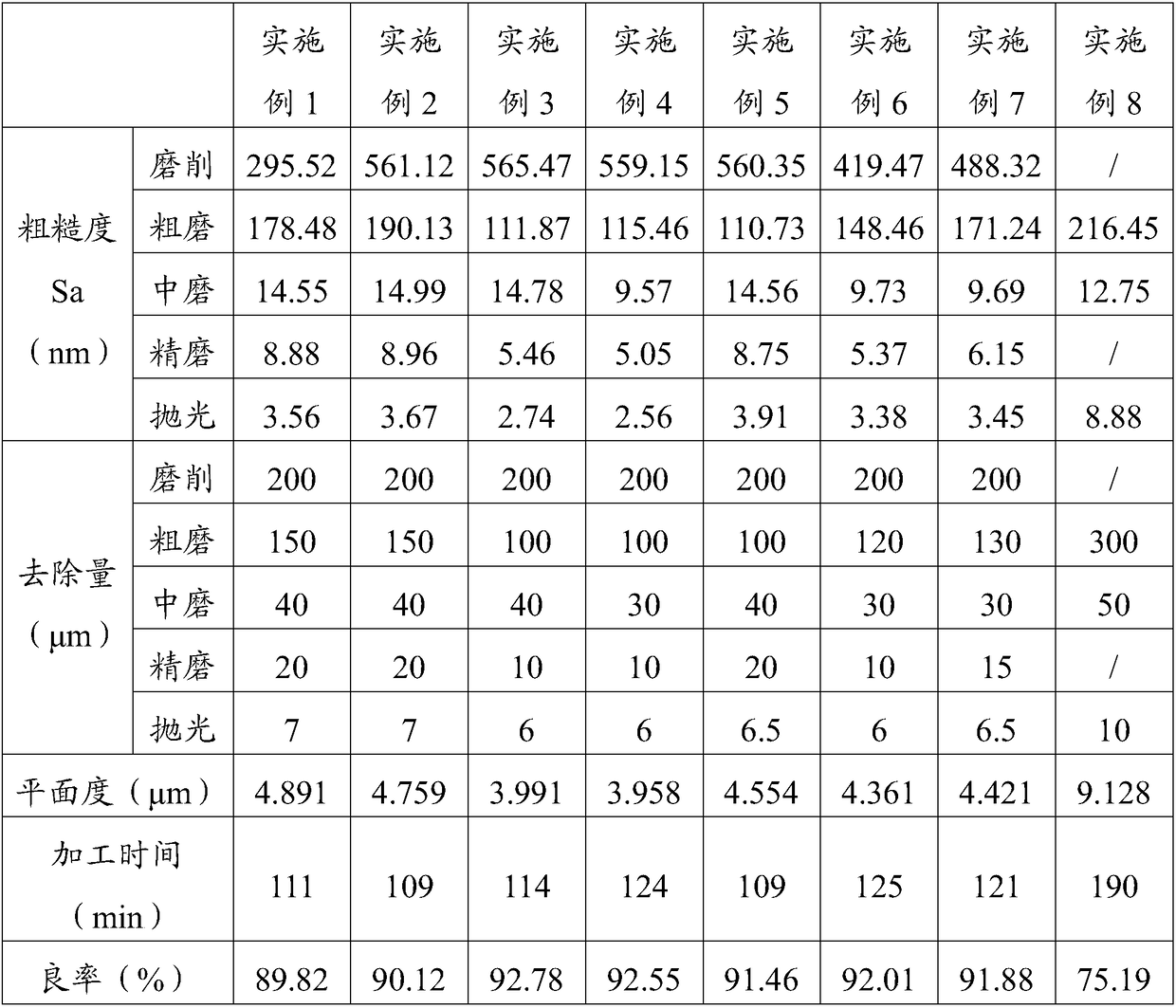

Embodiment 1

[0106] (1) Grinding treatment of zirconia ceramics with grinding fluid and diamond grinding wheel. Among them, the particle size of the diamond abrasive used to prepare the diamond grinding wheel is 80 μm; the linear speed of the diamond grinding wheel is 35 m / s, the spindle speed is 1100 r / min, and the back cutting amount is 0.015 mm; the time for grinding is 6 min.

[0107] (2) The ground zirconia ceramics were roughly ground with boron nitride grinding liquid and cast iron disk. Among them, the boron nitride grinding liquid includes 30g of boron nitride fine powder, 2g of dispersant polyoxyethylene ether, 1g of suspending agent polyacrylamide, 1g of antirust agent dimethylformamide and 90g of water, boron nitride The particle size of the micropowder is 65μm, and the material of the cast iron disc is ductile iron; during rough grinding, the rotational speed of the cast iron disc is 30r / min; the processing pressure is 100g / cm 2 , the flow rate of the boron nitride grinding l...

Embodiment 2

[0112] (1) Grinding treatment of zirconia ceramics with grinding fluid and diamond grinding wheel. Wherein, the particle size of the diamond abrasive for preparing the diamond grinding wheel is 180 μm; the linear speed of the diamond grinding wheel is 35m / s, the spindle speed is 1100r / min, and the back cutting amount is 0.02mm; the removal amount of the grinding process is 0.2mm; The grinding time is 4min.

[0113] (2) The ground zirconia ceramics were roughly ground with boron nitride grinding liquid and cast iron disk. Among them, the boron nitride grinding liquid includes 5g of boron nitride fine powder, 1g of dispersant nonylphenol polyoxyethylene ether, 0.1g of suspending agent sodium polyacrylate, 0.1g of antirust agent nitrogen nitrogen dimethylacetamide and 50g of water, the particle size of boron nitride micropowder is 65μm, and the material of the cast iron disc is gray cast iron; during rough grinding, the rotational speed of the cast iron disc is 30r / min; the proc...

Embodiment 3

[0118] (1) Grinding treatment of zirconia ceramics with grinding fluid and diamond grinding wheel. Wherein, the particle size of the diamond abrasive for preparing the diamond grinding wheel is 180 μm; the linear speed of the diamond grinding wheel is 35m / s, the spindle speed is 1100r / min, and the back cutting amount is 0.02mm; the removal amount of the grinding process is 0.2mm; The grinding time is 4min.

[0119] (2) The ground zirconia ceramics were roughly ground with boron nitride grinding liquid and cast iron disk. Wherein, the boron nitride grinding liquid includes 20g of boron nitride micropowder, 2g of dispersant triethanolamine, 1g of suspending agent sodium polyacrylate, 1g of antirust agent nitrogen nitrogen dimethylethanolamine and 80g of water, boron nitride micropowder The particle size of the cast iron disc is 45 μm, and the material of the cast iron disc is nodular cast iron; during rough grinding, the rotational speed of the cast iron disc is 40r / min; the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com