A kind of synthesis technique of chiral catalyst

A synthesis process, chiral technology, applied in the field of low-cost and high-efficiency synthesis process, can solve problems such as difficulty in realization, high energy consumption at low temperature control, and strong odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

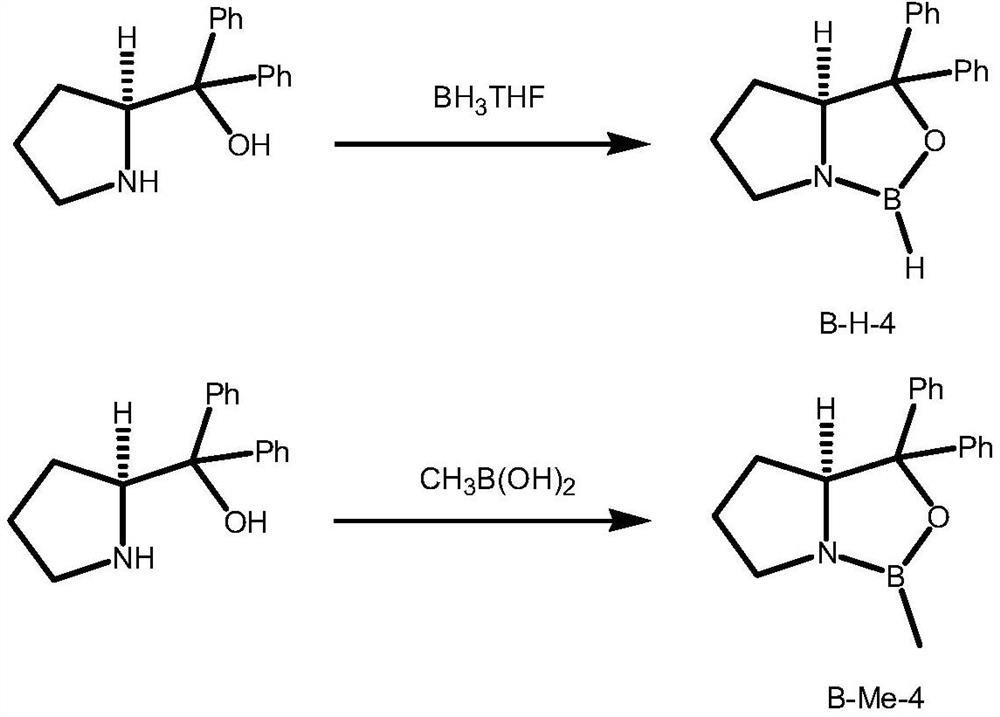

Method used

Image

Examples

Embodiment 1

[0077] The industrialized production of embodiment 1 (R)-diphenylprolinol hydrochloride

[0078]

[0079] 1. A 100-liter reactor was pumped into 22.0 kilograms of anhydrous methanol under nitrogen protection. Control the internal temperature of the reactor below 30°C. 7.0 kg of concentrated sulfuric acid (mass concentration 98%) is slowly pumped into the reactor. Open the lid of the reaction kettle, and quickly add 8.0 kg of D-proline. After the addition, adjust the inner temperature of the reaction kettle to 25-30° C., and continue stirring for 7 hours. The solvent was distilled off under reduced pressure at 55°C.

[0080] 2. Pump 35.0 kg of dichloromethane into the reactor. Cool down to 15°C, add 14.8 kg of sodium carbonate in batches, keep the temperature below 20°C during the addition, and continue stirring for 30 minutes after the addition. Pump the dichloromethane (11.2 kg) solution of di-tert-butyl dicarbonate (16.1 kg) into the supporting dropping tank of the re...

Embodiment 2

[0085] The industrialized production of embodiment 2 (R)-diphenylprolinol hydrochloride

[0086] 1. A 100-liter reactor was pumped into 22.0 kilograms of anhydrous methanol under nitrogen protection. Control the internal temperature of the reactor below 30°C. Slowly pump 7.0 kg of concentrated sulfuric acid into the reactor. Open the lid of the reaction kettle, and quickly add 8.0 kg of D-proline. After the addition, adjust the inner temperature of the reaction kettle to 25-30° C., and continue stirring for 7 hours. The solvent was distilled off under reduced pressure at 55°C.

[0087] 2. 34.3 kg of tetrahydrofuran was pumped into the reaction kettle. Cool down to 15°C, add 19.2 kg of potassium carbonate in batches, keep the temperature below 20°C during the addition, and continue stirring for 30 minutes after the addition. Pump the dichloromethane (11.2 kg) solution of di-tert-butyl dicarbonate (16.1 kg) into the supporting dropping tank of the reaction kettle, add dropwi...

Embodiment 3

[0090] The industrialized production of embodiment 3 (S)-diphenylprolinol hydrochloride

[0091]

[0092] 1. A 100-liter reactor was pumped into 22.0 kilograms of anhydrous methanol under nitrogen protection. Control the internal temperature of the reactor below 30°C. Slowly pump 7.0 kg of concentrated sulfuric acid into the reactor. Open the lid of the reaction kettle, and quickly add 8.0 kg of L-proline. After the addition, adjust the inner temperature of the reaction kettle to 25-30° C., and continue stirring for 7 hours. The solvent was distilled off under reduced pressure at 55°C.

[0093] 2. Pump 35.0 kg of dichloromethane into the reactor. Cool down to 15°C, add 14.8 kg of sodium carbonate in batches, keep the temperature below 20°C during the addition, and continue stirring for 30 minutes after the addition. Pump the dichloromethane (11.2 kg) solution of di-tert-butyl dicarbonate (16.1 kg) into the supporting dropping tank of the reaction kettle, add dropwise at...

PUM

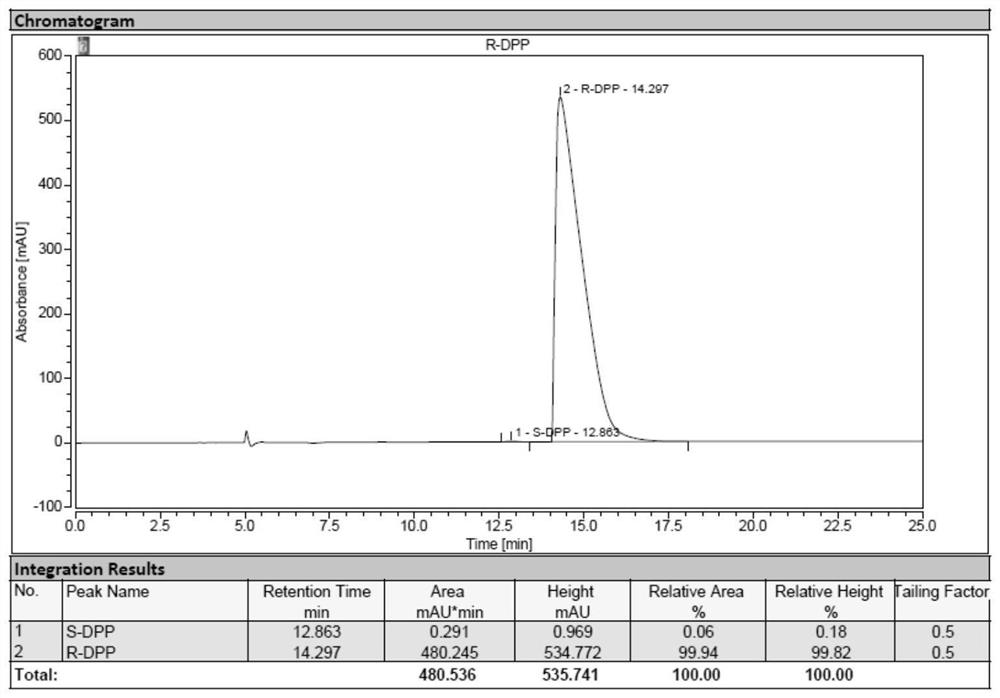

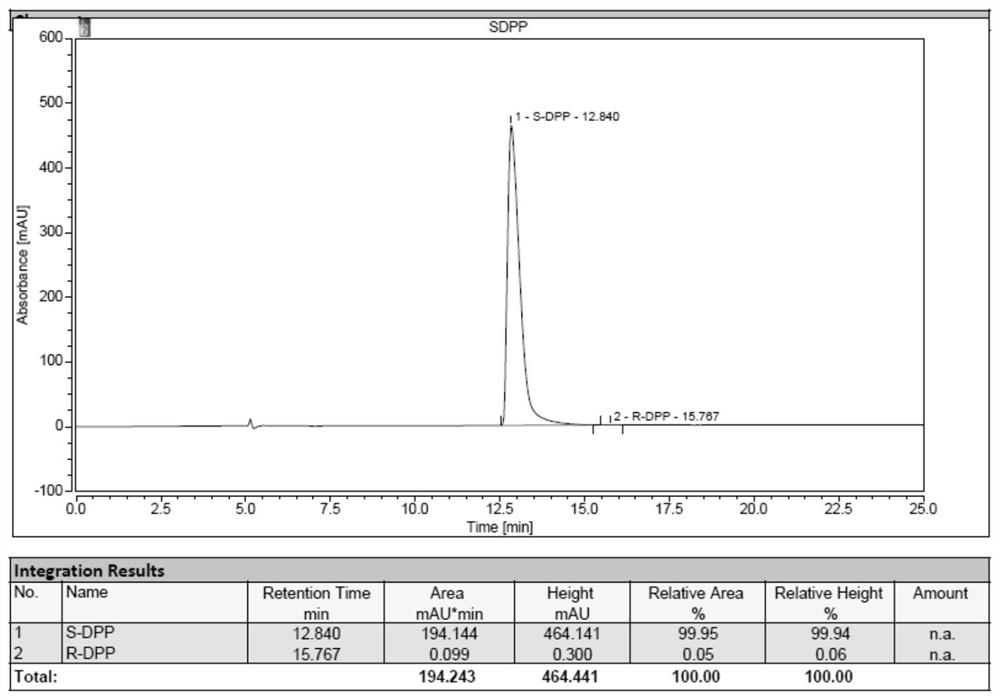

| Property | Measurement | Unit |

|---|---|---|

| enantiomeric excess | aaaaa | aaaaa |

| enantiomeric excess | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com