High-damping high-strength polyurethane foam

A polyurethane foam, high-strength technology, applied in the field of foam materials, can solve the problems of poor anti-seismic effect, low mechanical strength, low damping coefficient, etc., and achieve the effects of improved damping effect, simple synthesis steps and high damping coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

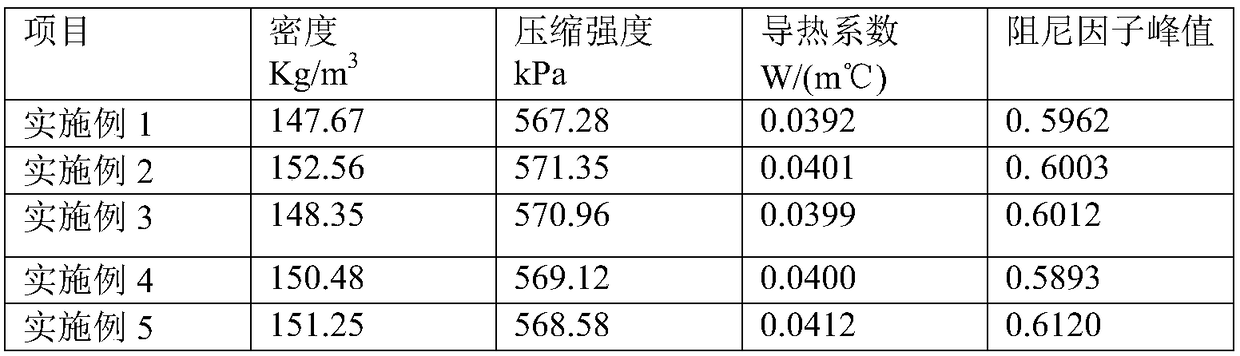

Examples

Embodiment 1

[0032] A high-damping high-strength polyurethane foam, said polyurethane foam comprises the following components in parts by weight: 50 parts of polyethylene glycol 400, 20 parts of polyester polyol, 5 parts of hydroxyfluorosilicone oil, dimethylene benzene 80 parts of diisocyanate, 20 parts of boron-titanium-magnesium whiskers, 10 parts of ammonium polyphosphate, 1 part of triethylenediamine, 0.5 part of water, 0.05 part of dibutyltin dilaurate, wherein the polyester polyol is aromatic The relative molecular weight range of the polyol is 2500g / mol, the viscosity of the hydroxyfluorosilicone oil is 250MPa·S, the refractive index is 1.39, and the fluorine content is 5%.

[0033] The preparation method of described boron titanium magnesium whisker is as follows:

[0034] (1) Precursor preparation: Add 10 parts of magnesium chloride, 10 parts of boric acid, 5 parts of water and 0.5 parts of polyvinylpyrrolidone into the reaction kettle according to parts by weight and stir to for...

Embodiment 2

[0038] A high-damping high-strength polyurethane foam, said polyurethane foam comprises the following components in parts by weight: 50 parts of polyethylene glycol 400, 30 parts of polyester polyol, 10 parts of hydroxyfluorosilicone oil, 1,4-cyclo 100 parts of hexane diisocyanate, 35 parts of boron titanium magnesium whiskers, 25 parts of ammonium polyphosphate, 3 parts of triethylenediamine, 3 parts of water, 0.25 parts of dibutyltin dilaurate, wherein the polyester polyol It is an aromatic polyol with a relative molecular weight range of 25,000 g / mol. The hydroxyfluorosilicone oil has a viscosity of 750 MPa·S, a refractive index of 1.42, and a fluorine content of 35%.

[0039] The preparation method of described boron titanium magnesium whisker is as follows:

[0040] (1) Precursor preparation: Add 10 parts of magnesium chloride, 20 parts of boric acid, 5 parts of water and 2 parts of polyvinylpyrrolidone into the reaction kettle according to parts by weight and stir to for...

Embodiment 3

[0044] A high-damping high-strength polyurethane foam, said polyurethane foam comprises the following components in parts by weight: 50 parts of polyethylene glycol 400, 25 parts of polyester polyol, 5 parts of hydroxyfluorosilicone oil, methyl-2, 85 parts of 4-diisocyanate, 26 parts of boron-titanium-magnesium whiskers, 16 parts of ammonium polyphosphate, 1 part of triethylenediamine, 0.5 part of water, 0.05 part of dibutyltin dilaurate, wherein the polyester polyol It is an aromatic polyhydric alcohol with a relative molecular weight range of 15000 g / mol. The viscosity of the hydroxyfluorosilicone oil is 550 MPa·S, the refractive index is 1.40, and the fluorine content is 25%.

[0045] The preparation method of described boron-titanium-magnesium whiskers is as follows:

[0046] (1) Precursor preparation: Add 10 parts of magnesium chloride, 15 parts of boric acid, 5 parts of water and 1 part of polyvinylpyrrolidone into the reaction kettle according to parts by weight and sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com